Product defect detection and location method, device and equipment and computer readable medium

A technology of product defect and positioning method, applied in the field of artificial intelligence, to achieve the effect of standardization and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

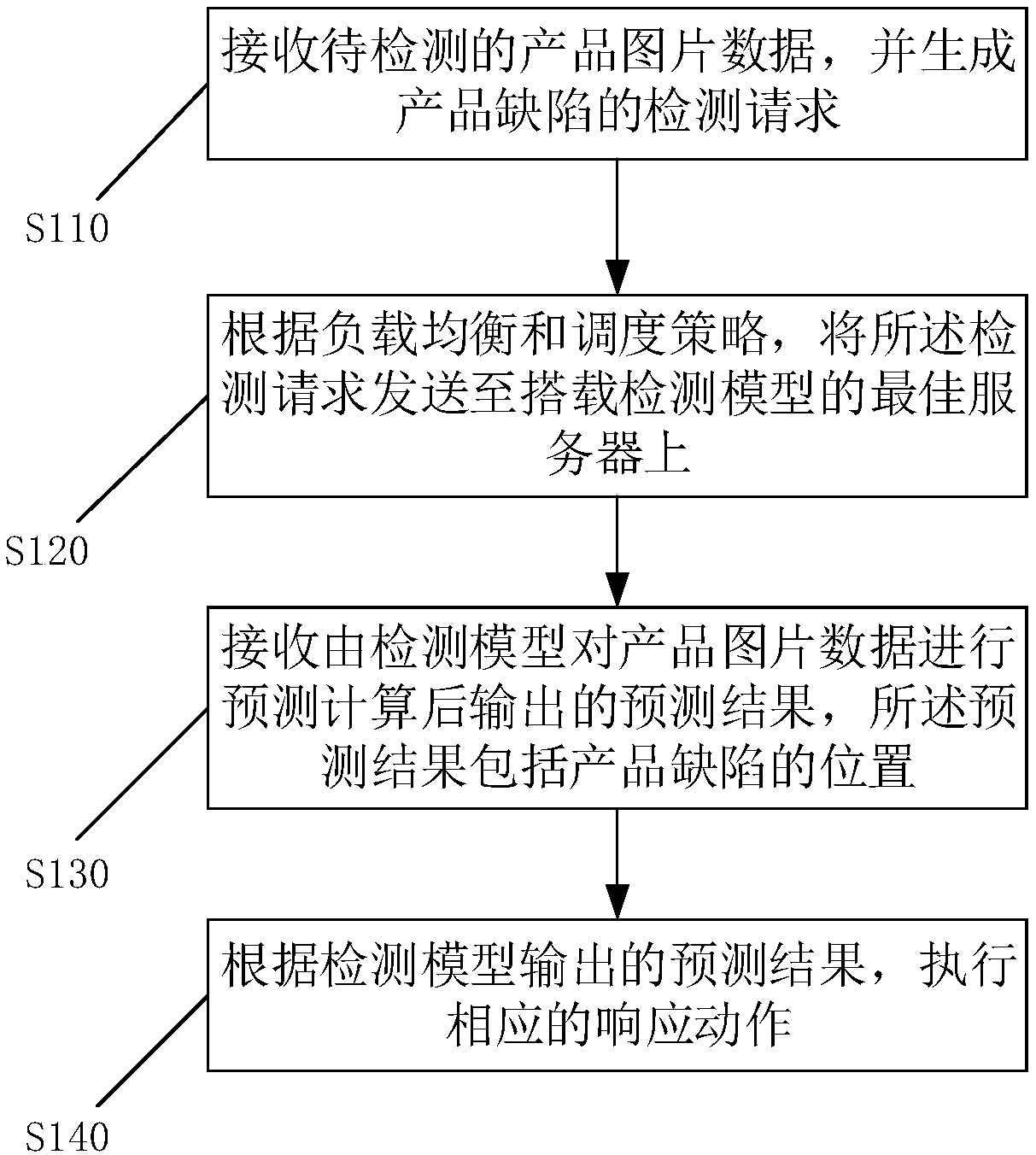

[0067] see figure 1 , which is a flowchart of the steps of the method for detecting and locating product defects in Embodiment 1 of the present invention. Embodiment 1 provides a method for detecting and locating product defects, including the following steps:

[0068] S110: Receive product image data to be detected, and generate a product defect detection request.

[0069] When it is necessary to detect the surface defect of the product, the image of the product surface can be collected first, for example, it can be collected by a camera and other equipment. Then, after the image information of the corresponding product is collected, a detection request is generated to detect surface defects of the product.

[0070] S120: Send the product image data and the detection request to the optimal server equipped with the detection model according to the load balancing and scheduling strategy.

[0071] Before sending the detection request, first monitor the deployment of the detec...

Embodiment 2

[0081] The difference from Embodiment 1 is that this Embodiment 2 also updates the detection model on the basis of Embodiment 1. The specific scheme is as follows:

[0082] see Figure 4 , which is a flow chart of the steps of the method for detecting and locating product defects in the second embodiment. Embodiment 2 provides a method for detecting and locating product defects, including the following steps:

[0083] S210: Receive product image data to be detected, and generate a product defect detection request.

[0084] S220: Send the product picture data and the detection request to the best server equipped with the detection model according to the load balancing and scheduling strategy.

[0085] S230: Receive a prediction result output after the detection model predicts and calculates the product image data, the prediction result includes the position of the product defect.

[0086] S240: Execute a corresponding response action according to the prediction result output...

Embodiment 3

[0091] see Figure 5 , which is a flow chart of the steps of the method for detecting and locating product defects in the third embodiment. Embodiment 3 provides a method for detecting and locating product defects, including the following steps:

[0092] S310: Receive product image data and a detection request for product defects.

[0093] S320: Carry out a prediction calculation of product defect on the image data of the product through the detection model and output a prediction result, the prediction result including the position of the product defect.

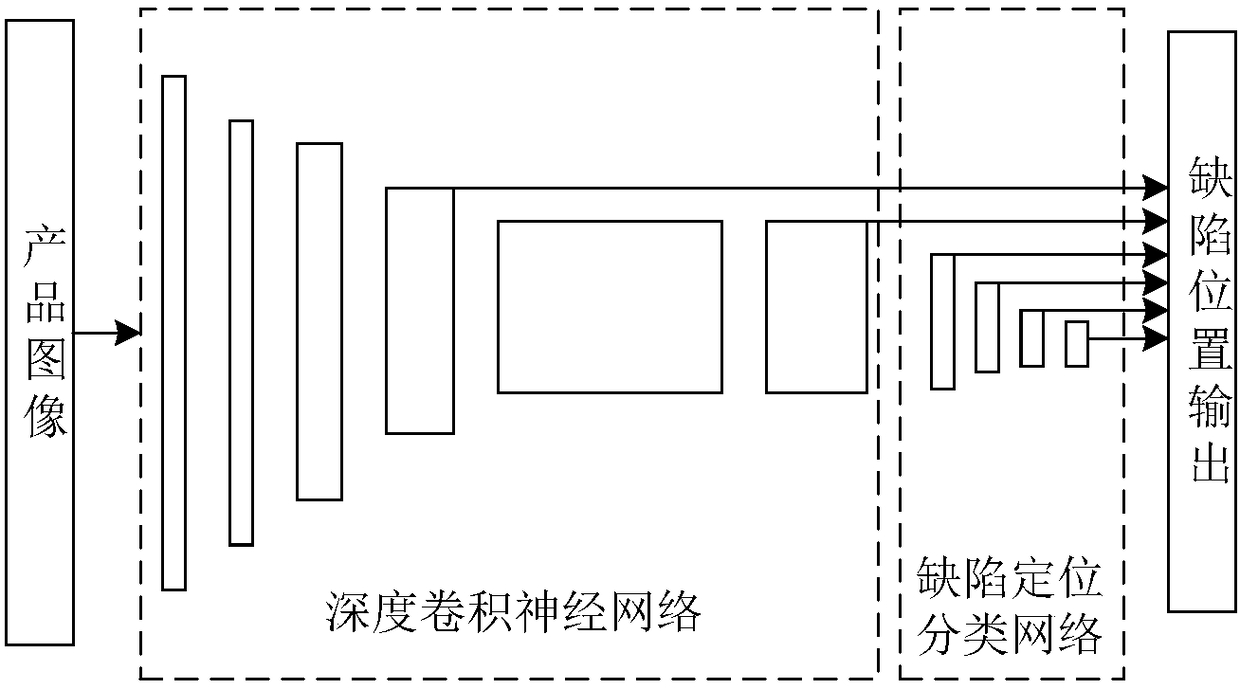

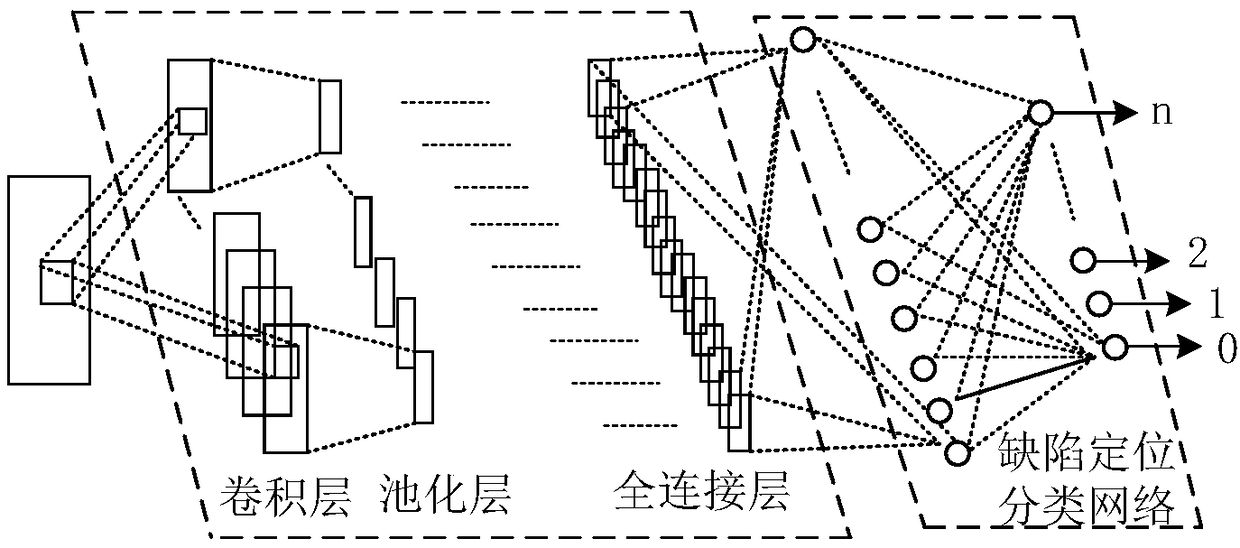

[0094] Wherein, the detection model includes: a deep convolutional neural network and a defect location and classification network.

[0095] The deep convolutional neural network is used to extract features of product images, and the features are input into the defect location and classification network.

[0096] The defect location classification network is used to judge whether there is a defect in the features extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com