Array substrate, display panel and array substrate manufacturing method

An array substrate and manufacturing method technology, applied in the field of thin-film transistor liquid crystal display, can solve the problems of cumbersome array substrate manufacturing process and difficulty in improving production capacity, and achieve the effects of reducing product defects, increasing production capacity, and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

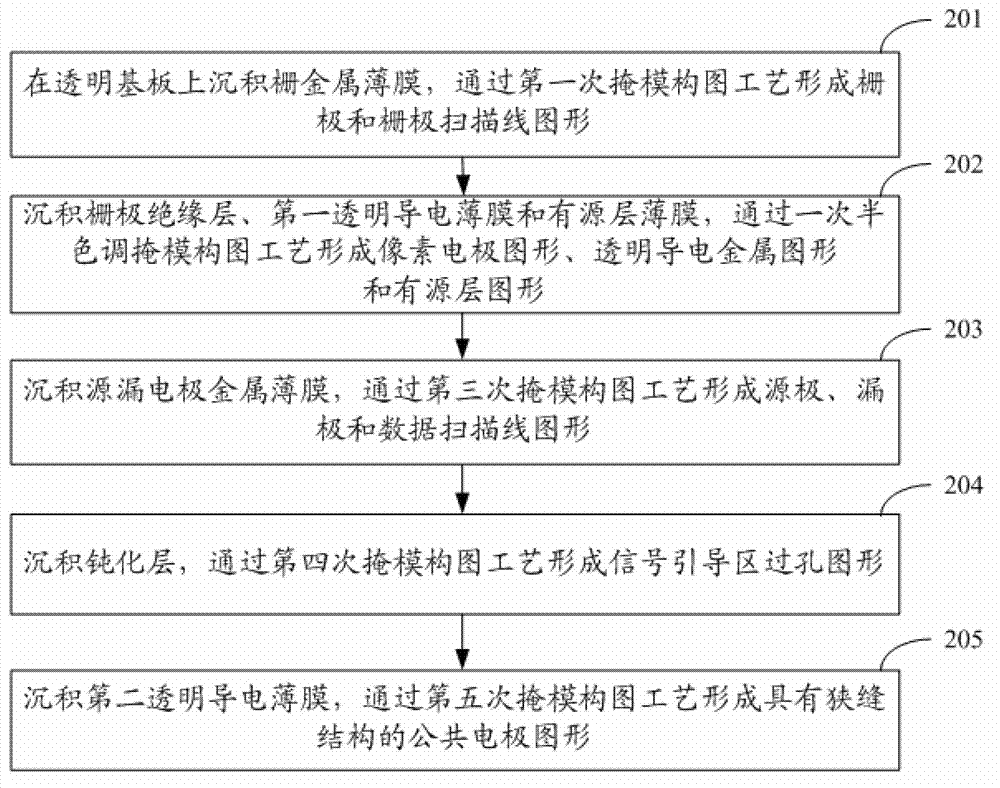

[0032] In order to solve the technical problems in the prior art that the manufacturing process of the array substrate is relatively cumbersome and the production capacity is difficult to increase, an embodiment of the present invention provides an array substrate, a display panel and a method for manufacturing the array substrate.

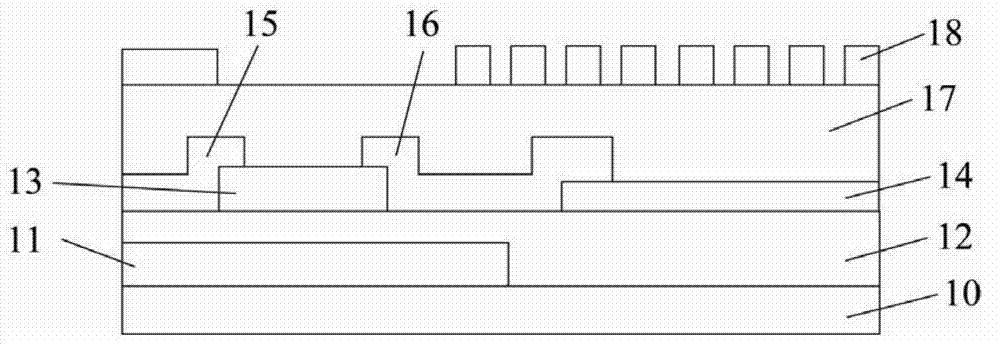

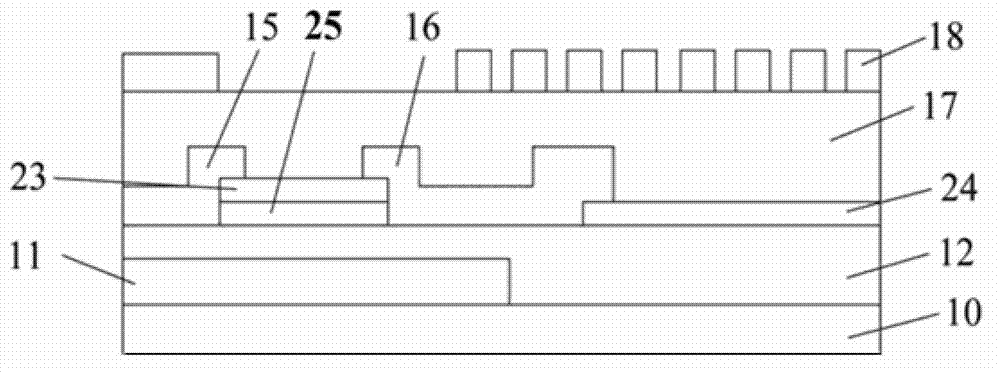

[0033] Such as Figure 6 In the illustrated embodiment, the array substrate of the present invention includes a plurality of pixel units (a cross section of a pixel unit is taken as an example in the figure), each pixel unit includes a thin film transistor, a transparent conductive metal layer 25 and a pixel electrode 24, and the thin film transistor Including gate 11, active layer 23, source 15 and drain 16, wherein,

[0034] The active layer 23 is located above or below the gate 11;

[0035] The transparent conductive metal layer 25 is in stacked contact with the active layer 23;

[0036] The source 15 and the drain 16 form a channel of the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com