Defect detection control system and method for industrial camera

A defect detection, industrial camera technology, used in optical testing flaws/defects, measuring devices, image data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, embodiments of the present invention are described with reference to the drawings.

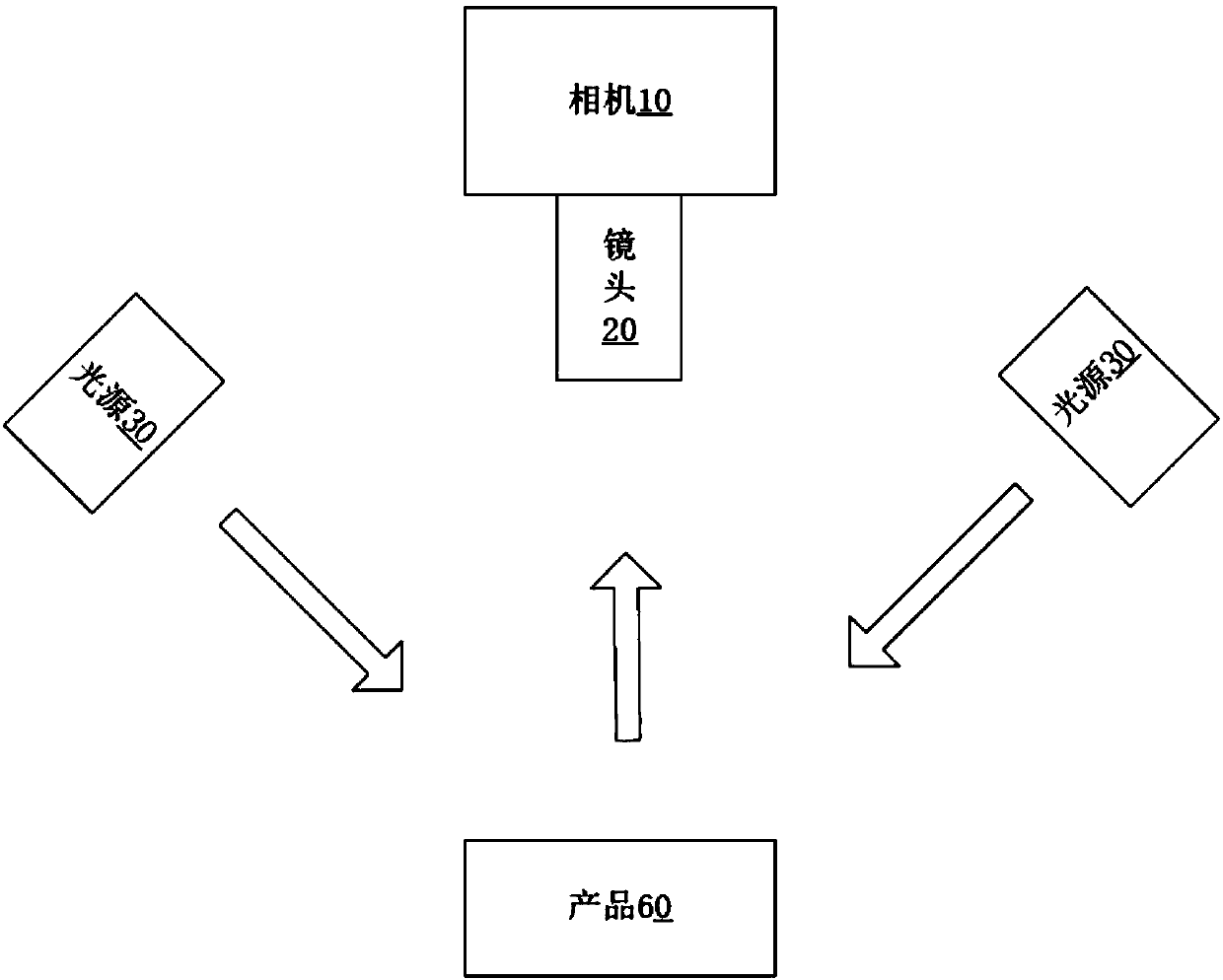

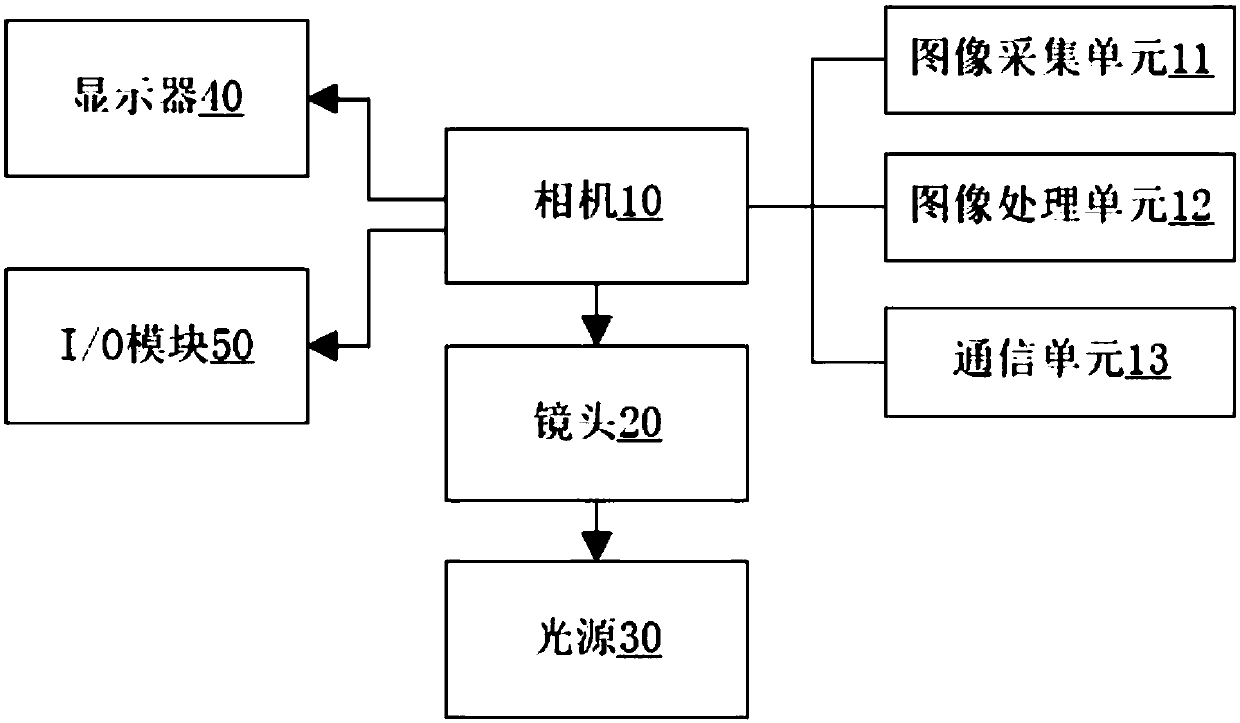

[0024] Such as figure 1 As shown, the defect detection system of an industrial camera includes a camera 10, a lens 20 connected to the camera, and a plurality of light sources 30, wherein the plurality of light sources face the front of the product 60 at different angles, and the main control unit of the camera controls the plurality of light sources The lighting sequence of the camera, and at the same time start the image acquisition unit of the camera to take pictures and generate multiple photos;

[0025] The camera includes an image processing unit, and the image processing unit includes a plurality of fixed modules packaged into algorithms for image processing and comparison of multiple photos;

[0026] The image processing unit has an image synthesis module packaged as a fixed module, a positioning search module, a preprocessing module, a Blob analysis module an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com