Single-side light-entering-type light guide plate defect extraction method

An extraction method and technology for light guide plates, which are used in optical testing of flaws/defects, material analysis by optical means, image data processing, etc., which can solve the problems of difficult quality standards for metrology tools, high mobility of operators, and differences in subjective identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

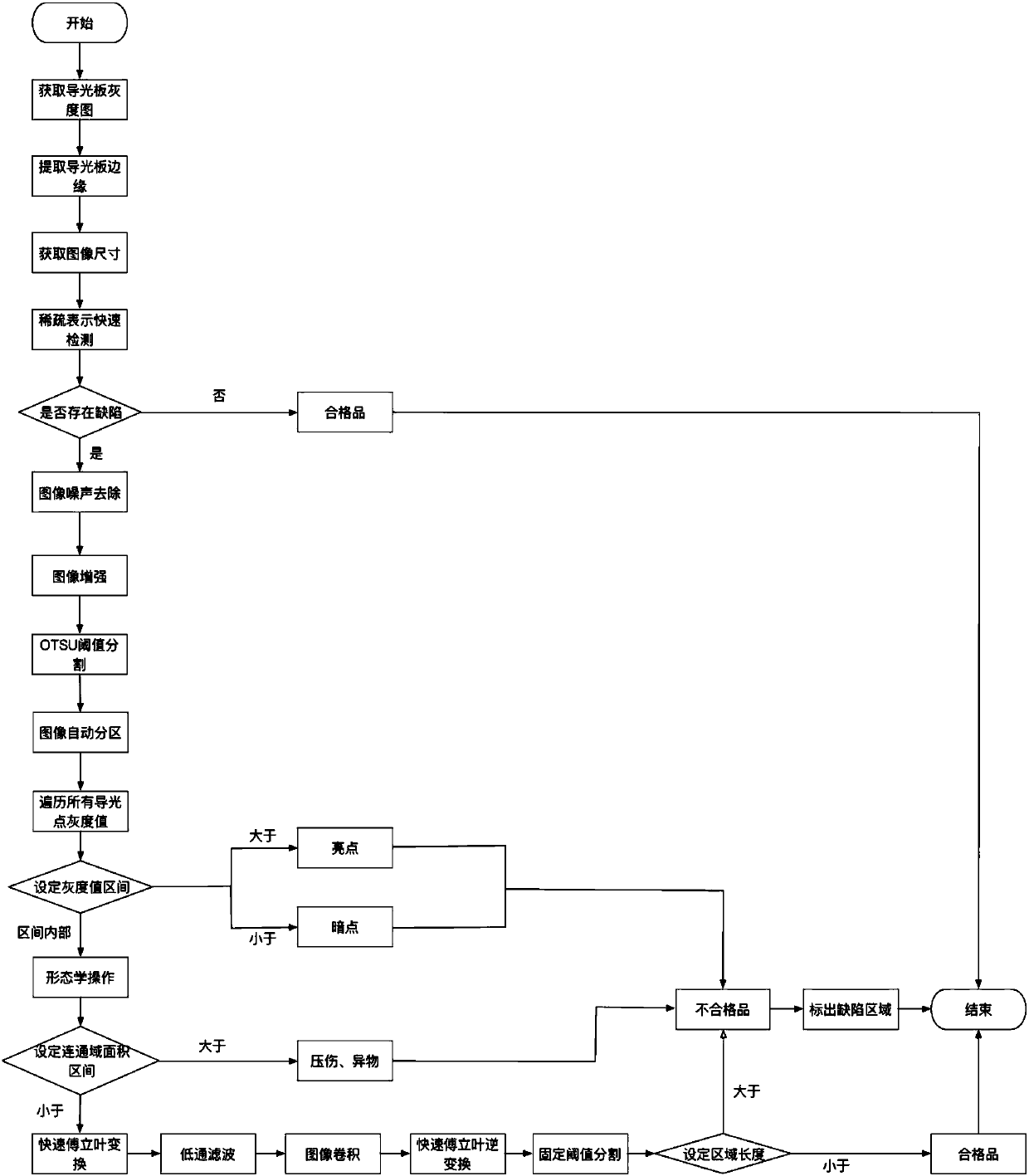

[0084] Embodiment 1. A method for extracting defects from a unilateral side light incident type light guide plate, such as Figure 1-19 as shown,

[0085] (1) Adopt the 16k line scan camera of Dalsa Company to obtain the light guide plate image F of high-precision grayscale; perform step 2;

[0086] After observation, various density and different sizes of light guide points can make the light guide plate emit light evenly. The production accuracy of the light guide plate is relatively high, and the defects of the light guide plate are generally very small. In order to detect the defects of the light guide plate, it is necessary to use a high-resolution line scan camera for imaging.

[0087] (2) Remove the edge interference of the detection workbench and extract the main part of the light guide plate; perform step 3;

[0088] First, the Gaussian filter is used to denoise the light guide plate image F(X, Y), and the smoothed image G(X, Y) is as follows

[0089] G(X,Y)=H(X,Y,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com