Intelligent detecting device for detecting defects of multi-type irregularly shaped product

A defect detection and intelligent detection technology, which is applied in the direction of measuring devices, optical devices, and material analysis through optical means, can solve problems such as lack of intelligence, achieve good shooting effects, realize automation and intelligence, and save manpower Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

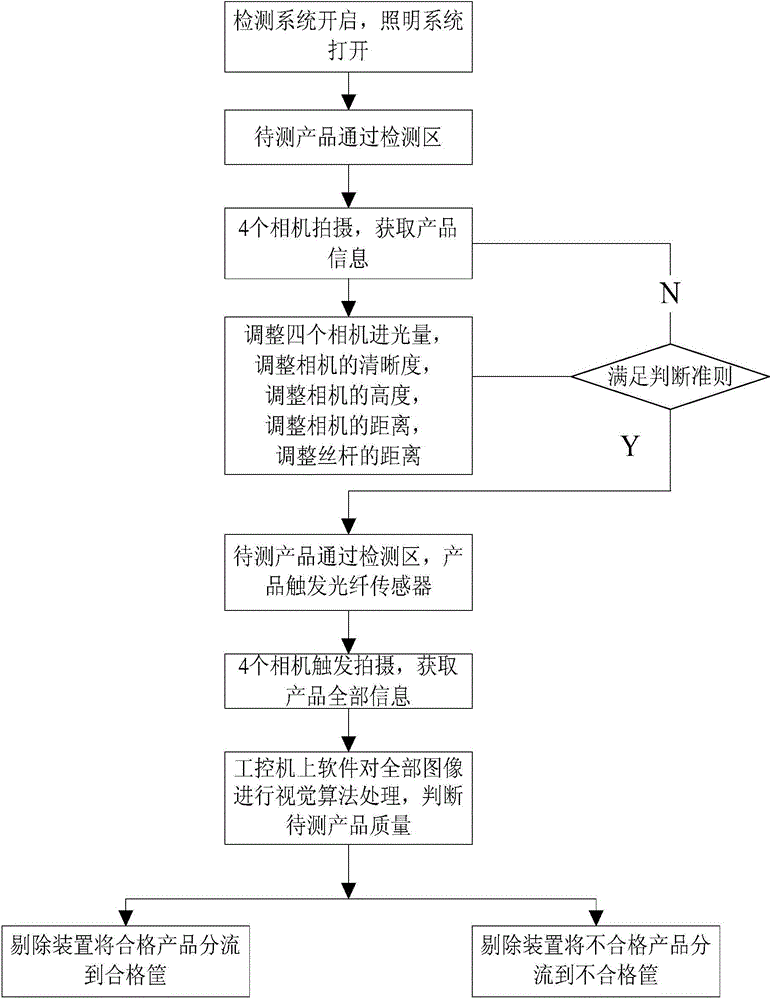

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

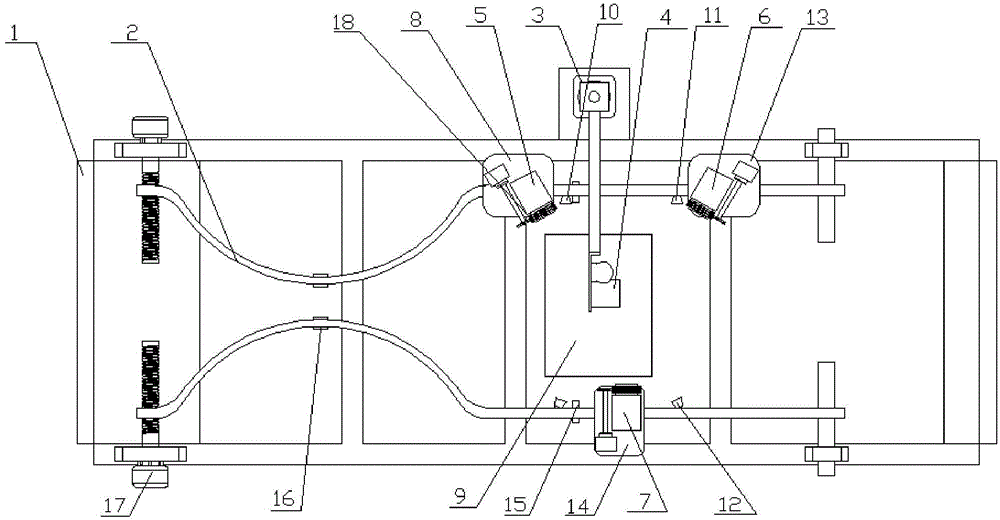

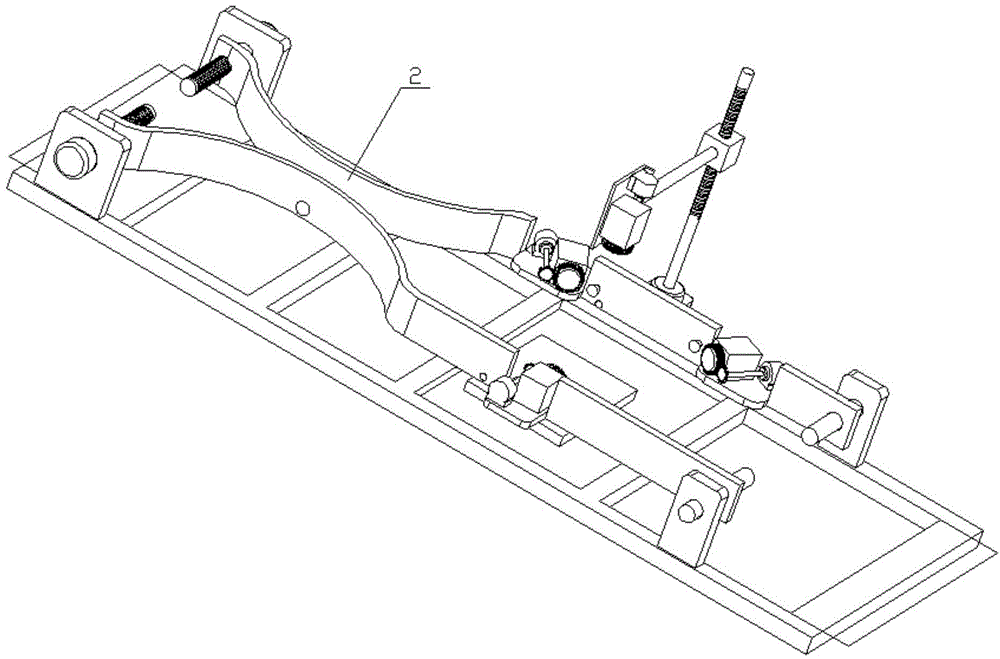

[0023] like figure 1 , figure 2 Shown is an intelligent detection device capable of detecting defects of multi-model irregular-shaped products, including a glass slide table 1, a bottleneck feeding mechanism, an image acquisition system, and an industrial computer.

[0024] The glass slide 1 is installed on the frame with an inclination angle of 30° relative to the horizontal plane. A vertical plane S is defined in the direction of the slope of the glass slide 1, and the vertical plane S divides the glass slide 1 into two left and right sides. area.

[0025] The bottleneck feeding mechanism includes two scoop-shaped baffles 2 with the same structural size. The spoon openings of the two scoop-shaped baffles 2 are set opposite to and symmetrical to the vertical plane S. The scoop-shaped baffles 2 are arranged on the glass slide 1 above, to limit the movement area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com