Novel hole puncher

A punching machine, a new type of technology, is applied in the direction of paper/cardboard containers, containers, bag making operations, etc. It can solve the problems of inconvenient adjustment, time-consuming and laborious, etc., and achieve the effect of ensuring the quality of punching, simple operation, and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

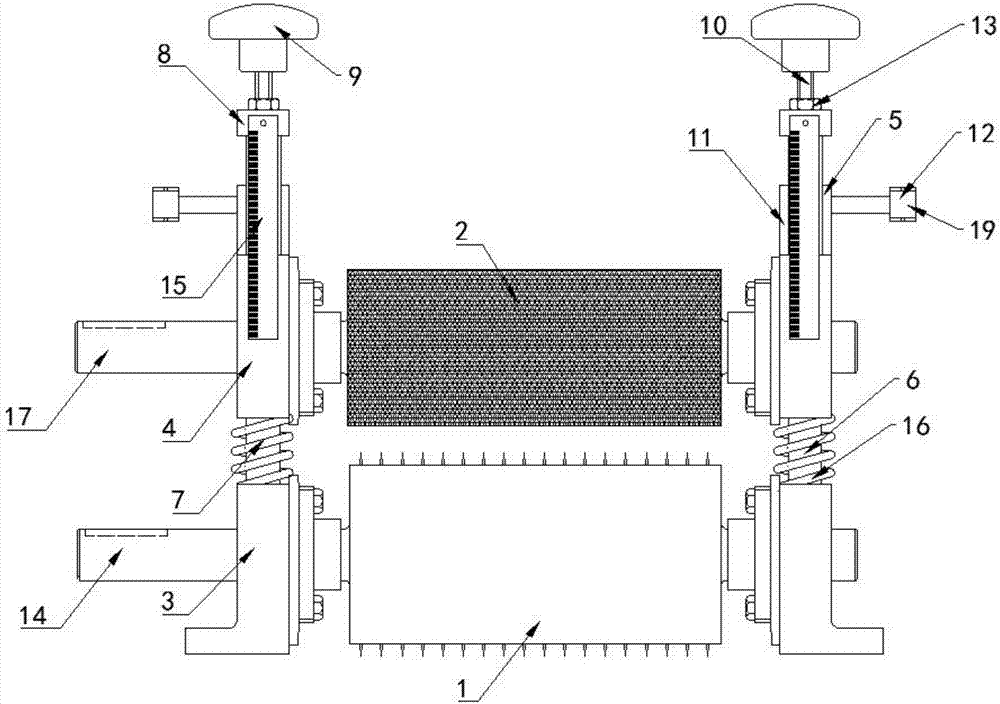

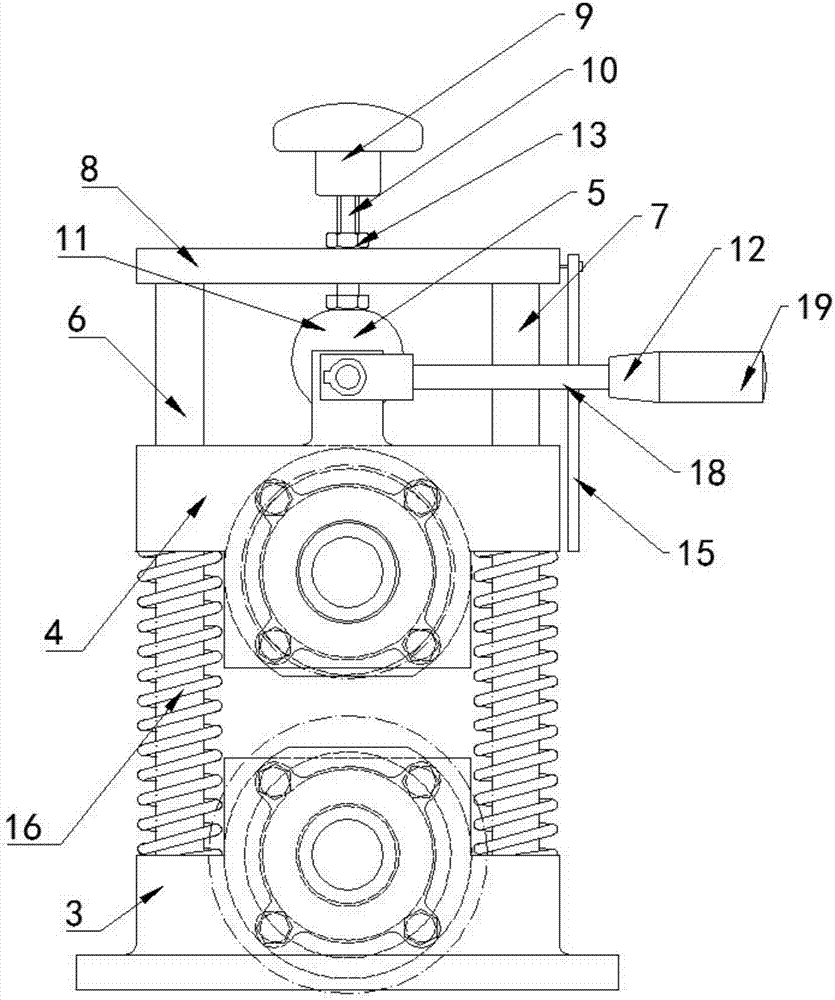

[0033] A new type of puncture machine, which is characterized in that it includes a cold puncture roller 1, a rubber roller 2, a lower bearing seat 3 symmetrically arranged at both ends of the cold puncture roller 1, an upper bearing seat 4 symmetrically arranged at both ends of the rubber roller 2, and a symmetrical arrangement A height adjustment device 5 that drives the upper bearing seat 4 to move in the vertical direction above the upper bearing seat 4;

[0034] A vertical shaft group 6 is symmetrically provided at both ends of the lower bearing seat 3. The vertical shaft group 6 includes two vertical shafts 7 arranged in parallel. Both ends of the upper bearing seat 4 are sleeved on the vertical shaft 7, and the upper bearing seat 4 and The lower bearing seat 3 is connected; a spring 16 for supporting the upper bearing seat 4 is arranged between the upper bearing seat 4 and the lower bearing seat 3, and the spring 16 is sleeved on the vertical shaft 7;

[0035] A top plate 8 ...

Embodiment 2

[0037] This embodiment is further optimized based on embodiment 1. A scale 15 is vertically arranged on one side of the top plate 8 so that the displacement of the rubber roller 2 in the vertical direction can be conveniently observed, so as to accurately control the rubber roller 2 and the cold puncture The gap between the rollers 1 ensures the puncture quality of the present invention.

Embodiment 3

[0039] This embodiment is further optimized based on embodiment 1. A second motor 17 is provided at one end of the upper bearing housing 4 to drive the rubber roller 2 to rotate. When the first motor 14 fails or is damaged, the second motor 17 can be used to drive the rubber The roller 2 rotates so that the present invention can still be used normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com