Electronic equipment stamping hardware piece and production process thereof

A technology for electronic equipment and production process, applied in the field of electronic equipment stamping hardware and its production process, can solve the problems of insufficient strength and low heat dissipation efficiency of heat sinks, and achieve the effects of increasing strength, good heat dissipation, and ensuring heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

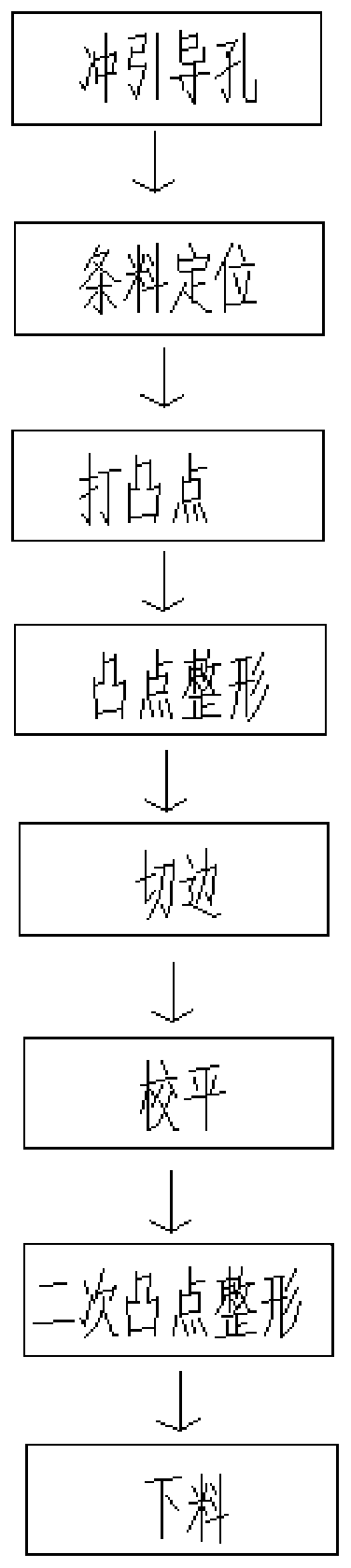

[0030] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

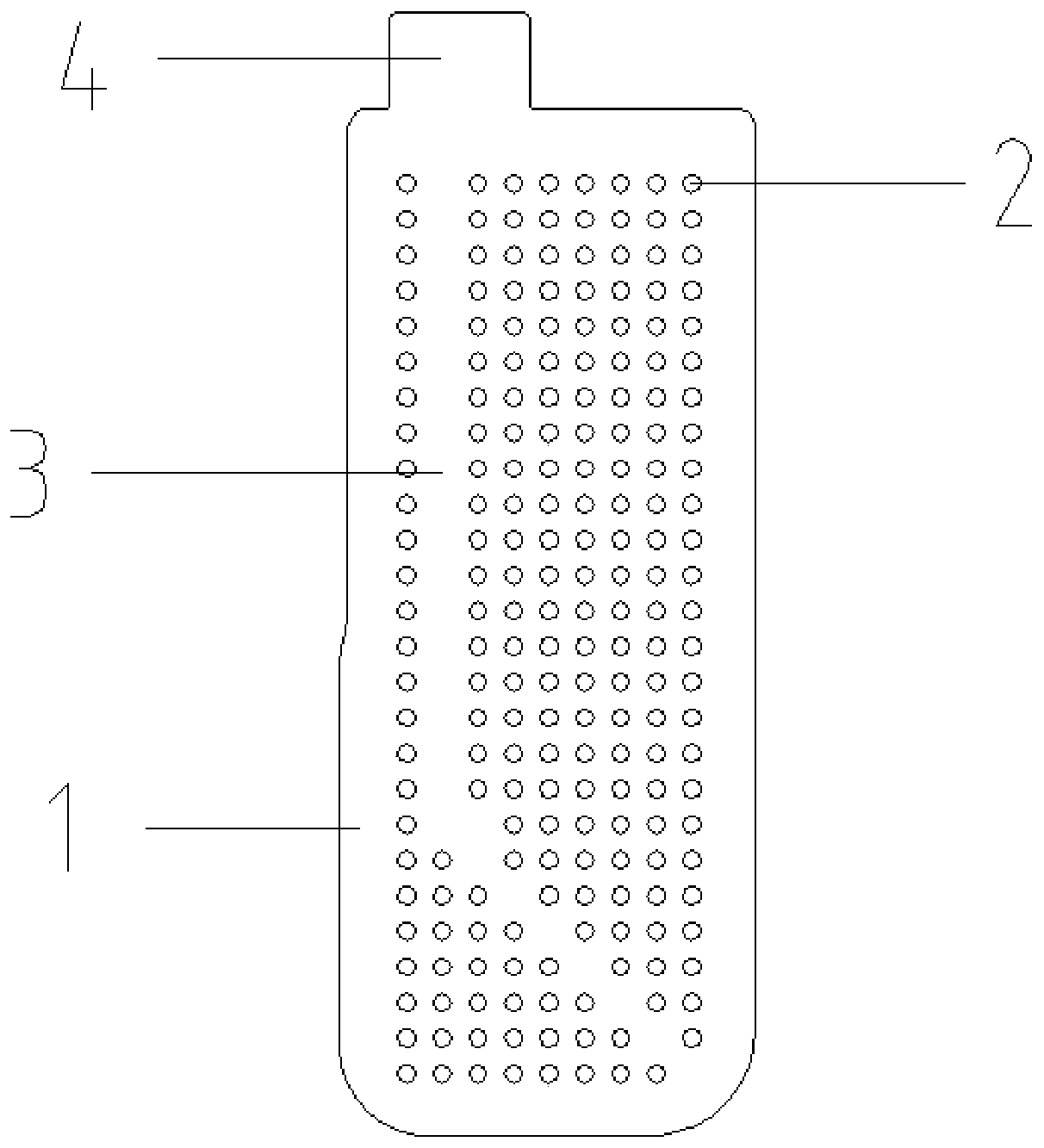

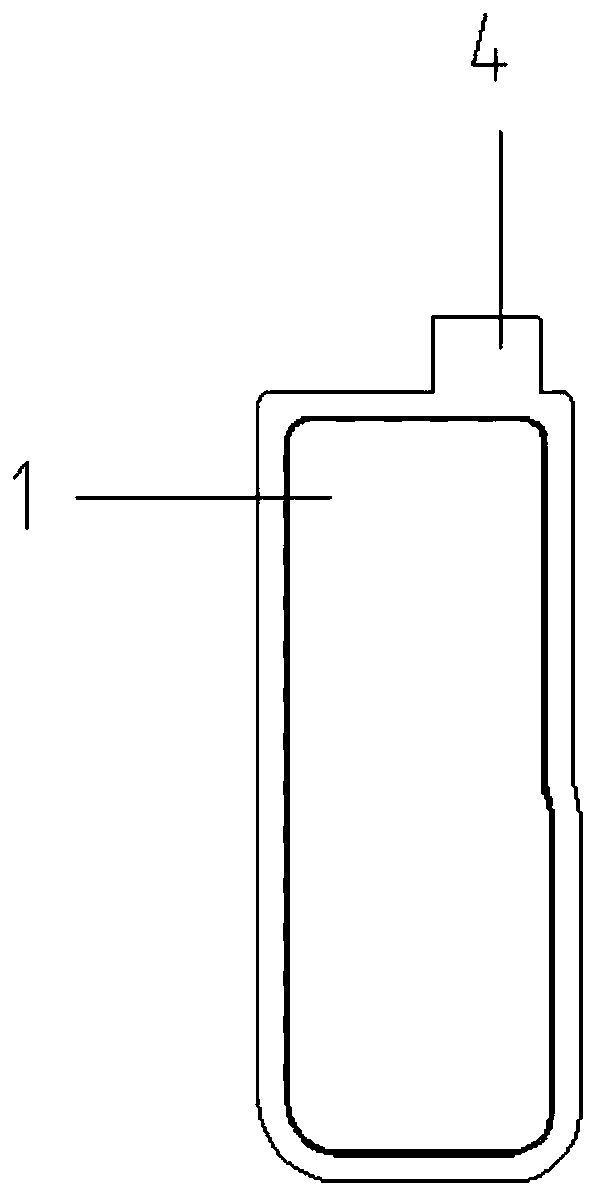

[0031] Such as Figure 1-2 As shown, this embodiment provides a stamping hardware for electronic equipment, the hardware is a sheet-like structure, one side of the sheet 1 is a smooth plane, and the other side of the sheet 1 is evenly distributed with outwardly protruding bumps 2 . The bumps include but not limited to bumps, bumps or ribs.

[0032] Further, the cut-off surface of each bump 2 includes but not limited to arc, circle and elongated shape, and the design of the bumps on the back increases the heat dissipation area, and at the same time strengthens the load-bearing strength and anti-pressure of the sheet ability.

[0033] Further, the thickness of the sheet 1 is 0.04mm-1mm, and the sheet material is a metal sheet or a non-metal sheet for heat transfer. The thickness of the heat sink is greatly reduced compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com