Composite hole laser punching method based on tip bright point guide

A laser drilling and composite hole technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult center positioning of the tip, unfavorable secondary drilling processing, and finding the tip of the taper hole, etc., to achieve The effect of solving positioning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

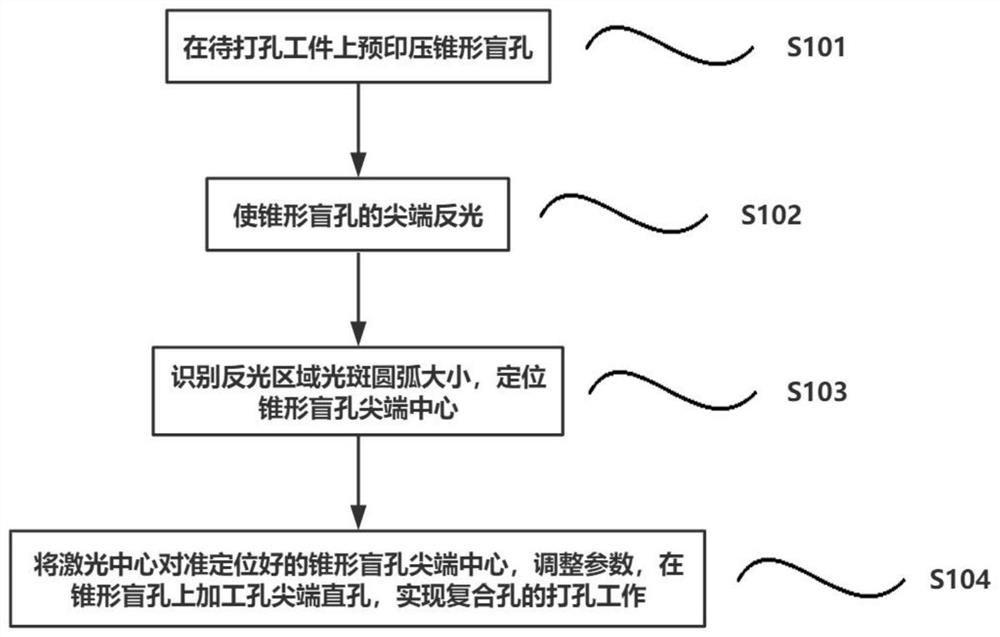

[0020] as attached figure 1 As shown, an embodiment of the present invention provides a laser drilling method for composite holes based on tip bright spot guidance, and the laser drilling method for composite holes includes the following steps:

[0021] S101, using a diamond-made conical indenter to press the metal sheet to form a tapered blind hole on the metal sheet; the tapered blind hole is also called a quasi-preformed tapered hole;

[0022] S102, irradiating the tapered blind hole with ordinary lighting light, so that the tip of the tapered blind hole reflects light;

[0023] S103, according to the image processing function of the positioning CCD, through high-precision contour extraction, arc fitting, and center extraction image processing algorithms, identify the arc size of the light spot in the reflective area, and locate the geometric center of the light spot; the geometric center of the light spot is is the tip center of the tapered blind hole;

[0024] S104, ali...

Embodiment 2

[0027] as attached figure 1 As shown, an embodiment of the present invention provides a laser drilling method for composite holes based on tip bright spot guidance, and the laser drilling method for composite holes includes the following steps:

[0028] S101, using a sapphire conical indenter to press the metal sheet to form a tapered blind hole on the metal sheet; the tapered blind hole is also called a quasi-preformed tapered hole;

[0029] S102, irradiating the tapered blind hole with ordinary lighting light, so that the tip of the tapered blind hole reflects light;

[0030] S103, according to the image processing function of the positioning CCD, through high-precision contour extraction, arc fitting, and center extraction image processing algorithms, identify the arc size of the light spot in the reflective area, and locate the geometric center of the light spot; the geometric center of the light spot is is the tip center of the tapered blind hole;

[0031] S104, align t...

Embodiment 3

[0034] as attached figure 1 As shown, an embodiment of the present invention provides a laser drilling method for composite holes based on tip bright spot guidance, and the laser drilling method for composite holes includes the following steps:

[0035] S101, using a diamond-made conical indenter to press the steel plate to form a tapered blind hole on the steel plate; the tapered blind hole is also called a quasi-preformed tapered hole;

[0036] S102, irradiating the tapered blind hole with ordinary lighting light, so that the tip of the tapered blind hole reflects light;

[0037] S103, according to the image processing function of the positioning CCD, through high-precision contour extraction, arc fitting, and center extraction image processing algorithms, identify the arc size of the light spot in the reflective area, and locate the geometric center of the light spot; the geometric center of the light spot is is the tip center of the tapered blind hole;

[0038] S104, ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com