Hole punching device and method for efficiently manufacturing plant leaf discs

A technology of punching device and plant leaves, which is applied in metal processing and other directions, can solve the problems of easily contaminated and sterile leaf discs, easy adhesion of leaf discs, and difficulty in dividing into a single tile for cultivation, etc., and achieves the effect of not easy pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are only used to illustrate the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased.

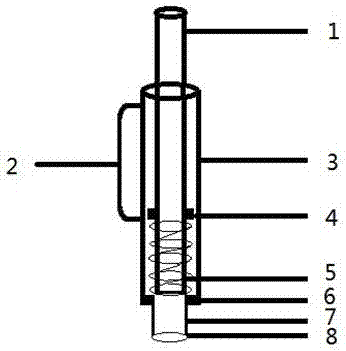

[0019] As shown in Figure 1, the punching device for efficiently making plant leaf discs of the present invention is composed of an operating rod 1 and a casing 3, and the spring 5 is put into the cavity of the casing 3, and the lower spring bayonet 6 at the bottom of the casing 3 Clamp the spring, put the operating rod 1 into the casing 3 and pass through the spring 5, the upper spring bayonet 4 clamps the operating rod, hold the operating handle 2 during use, and use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com