Computer case heat dissipation hole punching device

A punching device and heat dissipation hole technology, which is applied in the direction of punching tools, forming tools, manufacturing tools, etc., can solve the problems of low punching yield, easy punching breakage, small punch spacing, etc., to ensure accuracy and Yield rate, improvement of precision and quality, effect of guaranteeing corresponding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

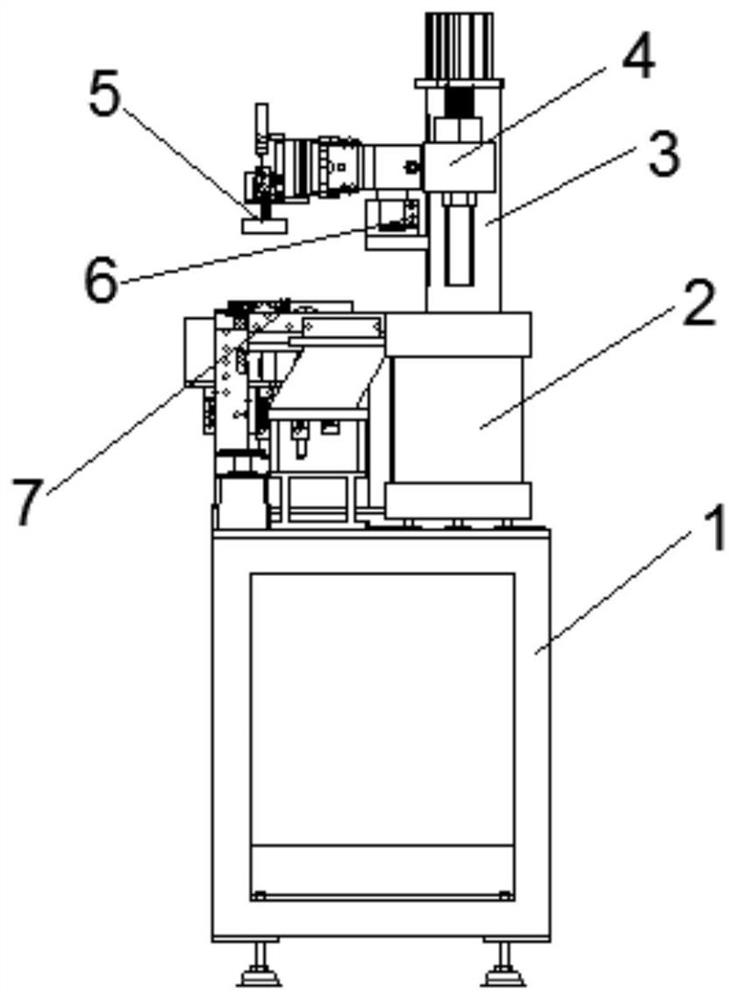

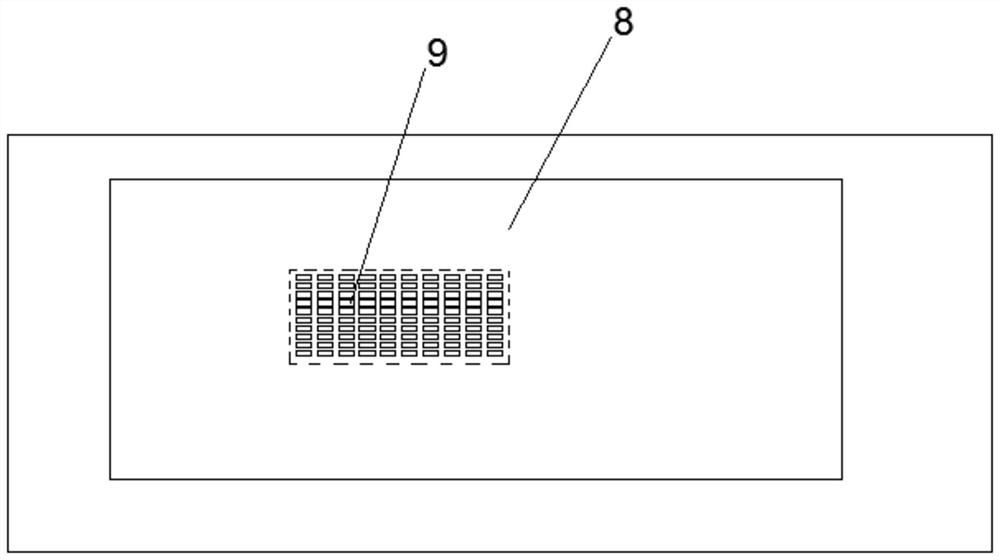

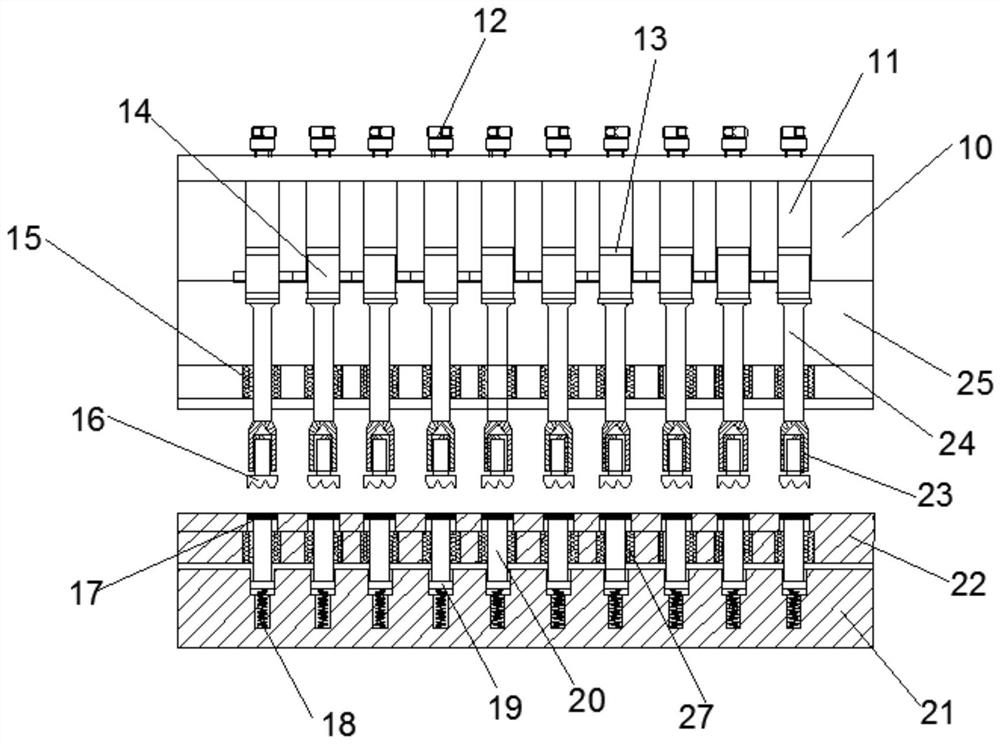

[0021] see Figure 1~4 , in an embodiment of the present invention, the computer case heat dissipation hole punching device includes a machine base 1, a machine table 2, a column 3, a driving slider 4, an auxiliary slide 6, an upper stamping die 5 and a lower stamping die 7, wherein, The top of the machine base is provided with the machine platform, one side of the machine platform is provided with a vertically extending column, and the top of the column is provided with a stamping lifting cylinder, and the column can slide up and down. The driving slider driven by the stamping lift cylinder is provided with a horizontally extending beam on the driving slider, and the auxiliary sliding seat is also provided between the beam and the side wall of the column. The beam The end of the upper stamping die 5 is provided, and the other side of the machine is provided with the lower stamping die 7 positioned below the upper stamping die. During the operation, first utilize the mutual p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com