Solidification and feeding method for complicated annular thin-wall shell steel casting

A technology for thin-walled shells and steel castings, applied in the field of steel castings, can solve problems such as shrinkage cavities, cracks, and shrinkage porosity, and achieve the effects of low cost, convenient operation, and reduced stress defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

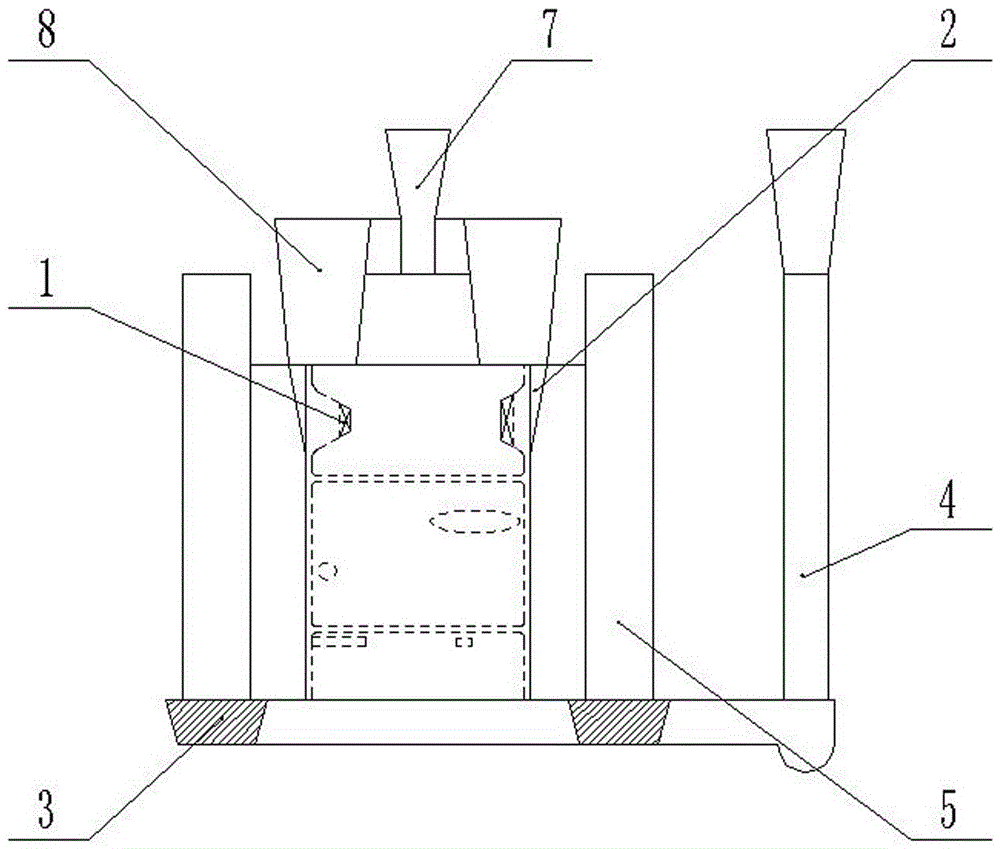

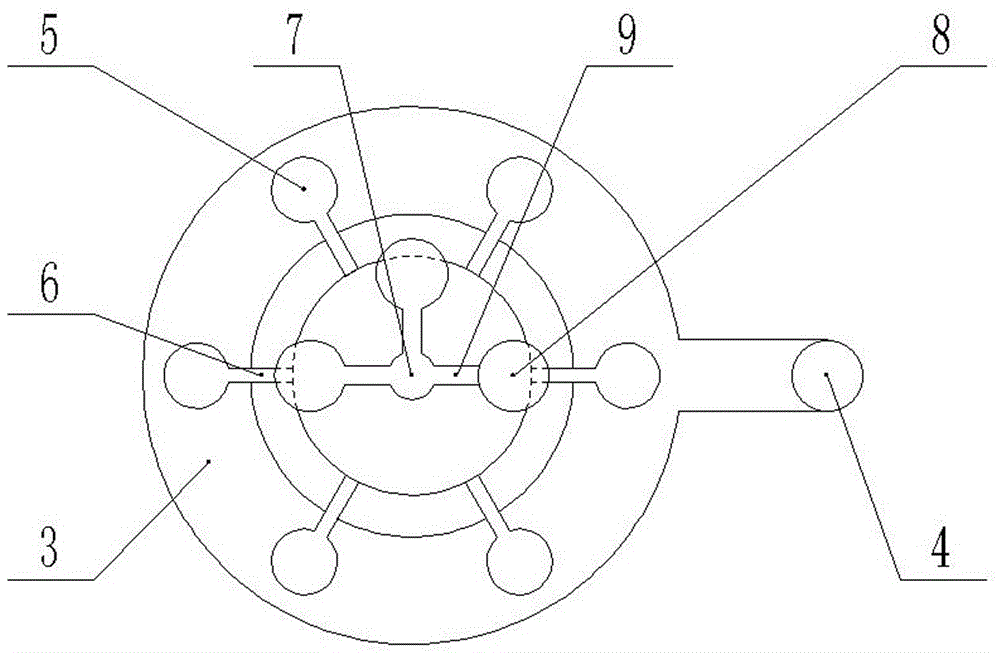

[0014] A solidification and feeding method for complex annular thin-walled shell steel castings, the following steps are adopted: a, making a steel casting sand mold cavity of a complex annular thin-wall shell steel casting, and a part of the inner cavity of the steel casting sand mold cavity Chill iron 1 is set on the hot section of the thick boss, and the inner cavity of the sand mold cavity of the steel casting is subsidized 2 for the boss design near the top; b. The gating system is made on the sand mold cavity of the steel casting, and the gating system includes the The annular runner 3 on the outside of the sand mold cavity, the outer side of the annular runner 3 is provided with a sprue 4 communicating with it, and the upper surface of the annular runner 3 is provided with a number of sand mold cavities connected with it and made of steel castings. The center is the slag collection cylinder 5 which is evenly distributed in the center of the circle. Between each slag coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com