Domestic garbage incinerator

A domestic waste incineration and furnace body technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of large equipment investment, high operating costs, and heavy workload, and achieve a high degree of automation, reduce incineration costs, and equipment The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

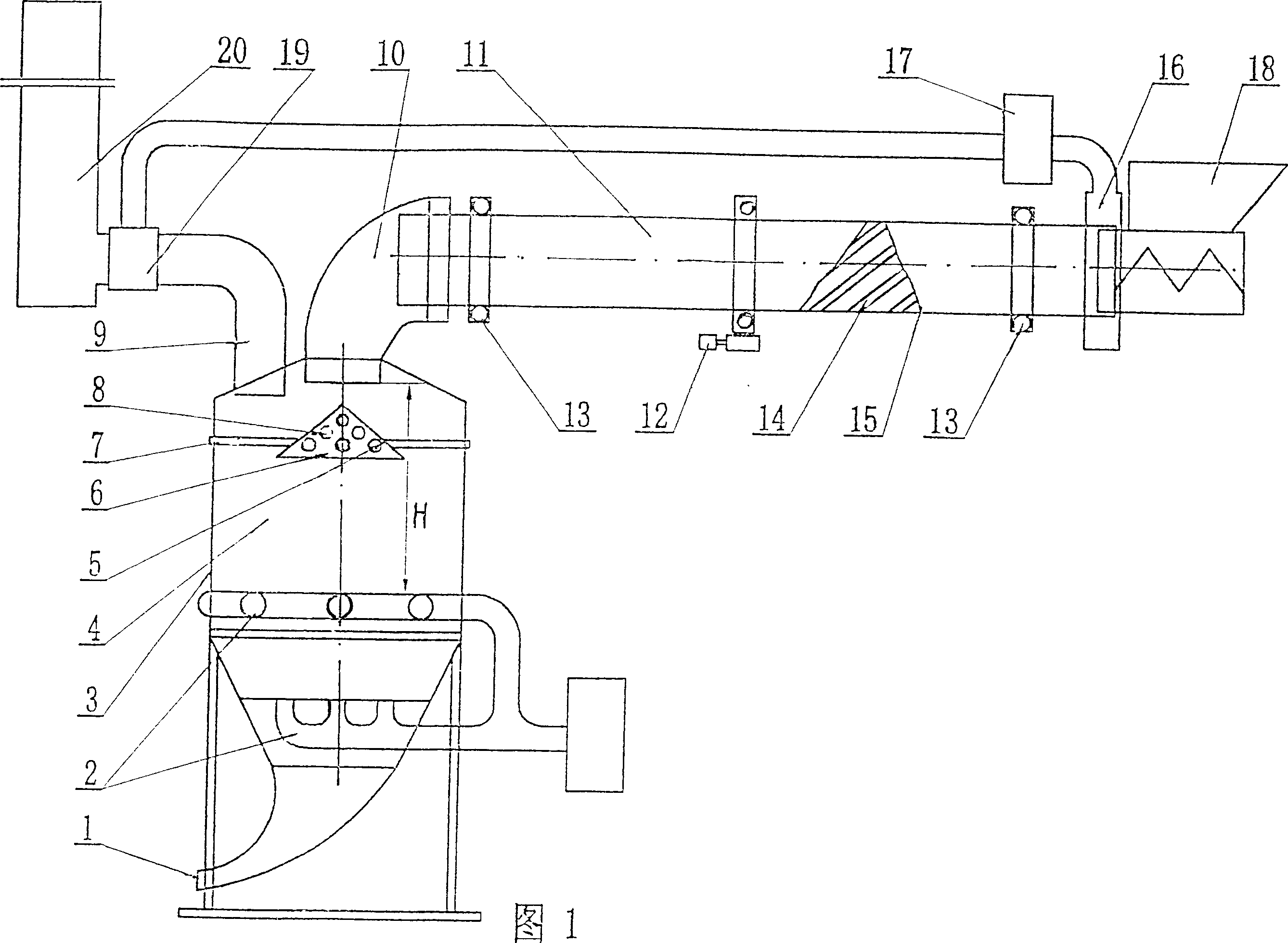

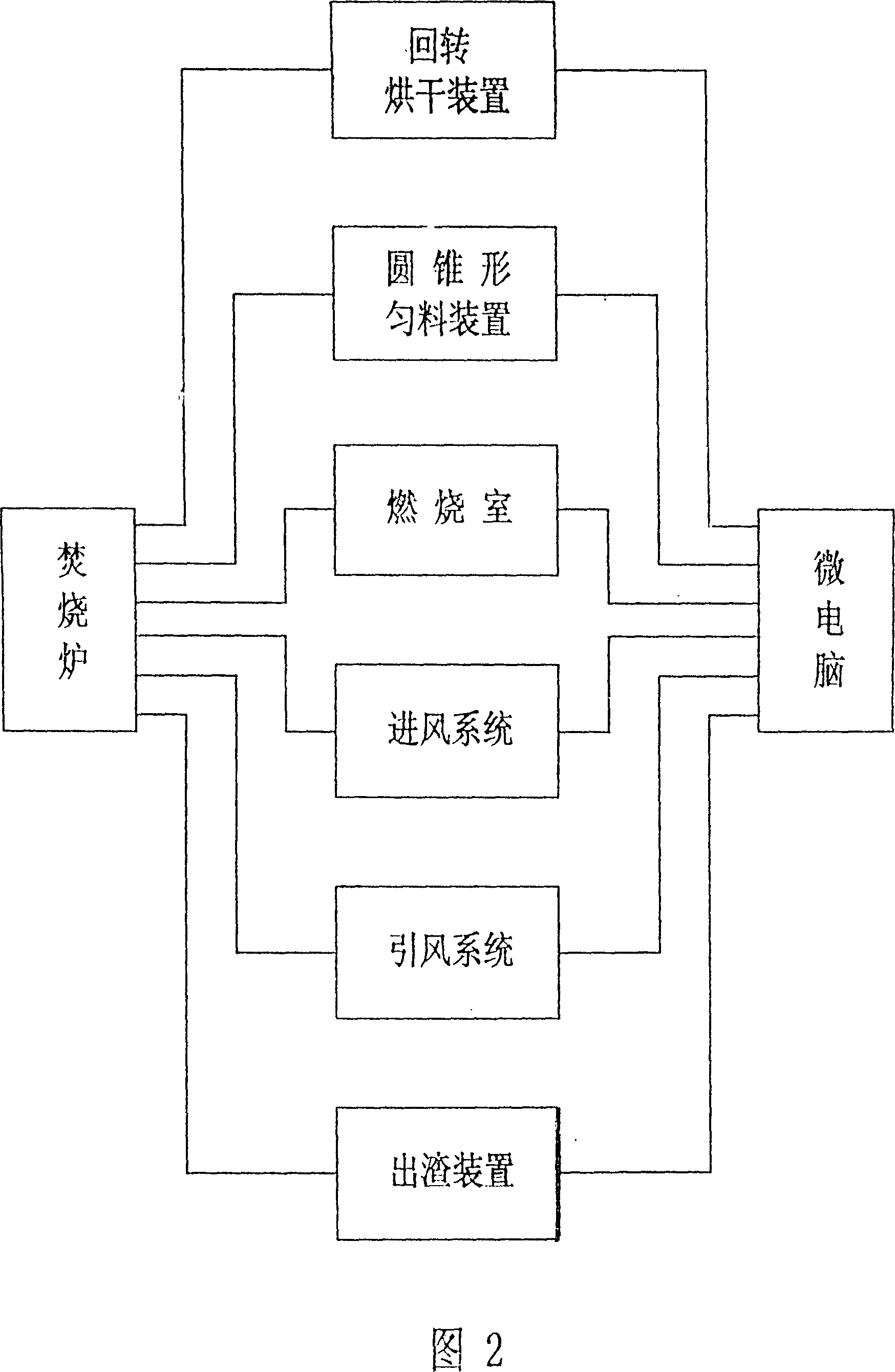

[0013] As shown in Figure 1: the present invention has a furnace body 3, a rotary drying device 11, a drying cylinder 15, a spiral bar 14, a bearing seat 13, a speed regulating motor 12, a flue gas outlet pipe 16, a feeding hopper 18, Blanking elbow 10, air induction system 17, conical material leveling device 5, conical material leveling cylinder 6, power rod 7, combustion chamber 4, smoke outlet 9, slag discharge device 1, air inlet system 2, round hole 8. Composed of a flue gas treatment device 19, a chimney 20 and a microcomputer. The middle of the furnace body 3 is a combustion chamber 4, and the upper part of the furnace body has a smoke outlet 9, which is connected to the chimney 20 after passing through a flue gas treatment device 19. wind system 2. A rotary drying device 11 is arranged on the furnace body. In the middle of the drying device is a drying cylinder 15, in which there is provided a spiral bar 14 that advances spirally from the feed hopper 18 to the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com