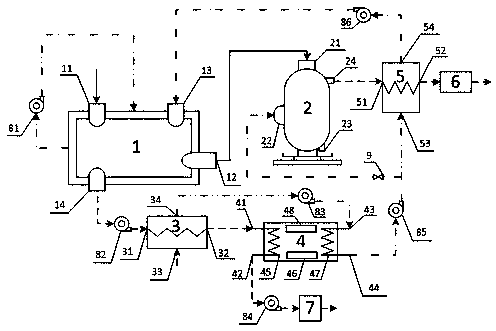

System and method of sludge by using drying incineration heat balance treatment

A sludge drying and treatment system technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as inability to achieve heat balance, achieve the effects of reducing disposal costs, improving conversion efficiency, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The dewatered sludge of a sewage treatment plant has a moisture content of 85%. The oxygen bomb calorimetry is used to measure the low calorific value of the sludge dry base to 3780kcal / kg. The wet sludge is placed in the drying device, and the temperature of the hot air inlet of the drying device is The air temperature is 200°C, and the odor outlet temperature is 75°C; the air temperature is increased by 20°C after preheating, and the air temperature is increased by 25°C after auxiliary heating, and the moisture content of the dried sludge is 30%. Exchange heat with air at 55°C, and the temperature of the hot air after heat exchange is 200°C. The heat generated by incineration and the heat required for drying can reach a heat balance.

Embodiment 2

[0046] The dewatered sludge of a sewage treatment plant has a moisture content of 55%. Part of the sludge is incinerated by oxygen bomb calorimetry to measure the low-level calorific value of the dry base of the sludge to be 1700kcal / kg. The wet sludge is placed in a drying device, and the drying device uses hot air The air inlet temperature is 120°C, and the odor outlet temperature is 55°C; the air temperature is increased by 10°C after preheating, and the air temperature is increased by 25°C after auxiliary heating, and the moisture content of the dried sludge is 10%, and the dried sludge is incinerated , The incineration flue gas exchanges heat with the air at 60°C, and the temperature of the hot air after the heat exchange is 120°C. The heat generated by incineration and the heat required for drying can reach a heat balance.

Embodiment 3

[0048] The dewatered sludge of a sewage treatment plant has a moisture content of 60%. The oxygen bomb calorimetry is used to measure the low-level calorific value of the sludge dry base to 2500kcal / kg. The wet sludge is placed in the drying device, and the temperature of the hot air inlet of the drying device is The air temperature is 200°C, and the temperature of the odor outlet is 70°C; the air temperature is increased by 20°C after preheating, and the air temperature is increased by 25°C after auxiliary heating, and the moisture content of the dried sludge is 20%. Exchange heat with air at 60°C, and the temperature of the hot air after heat exchange is 200°C. After the heat generated by incineration is used for sludge drying, the remaining heat is 1740kJ / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com