Acrylate production wastewater treatment process method

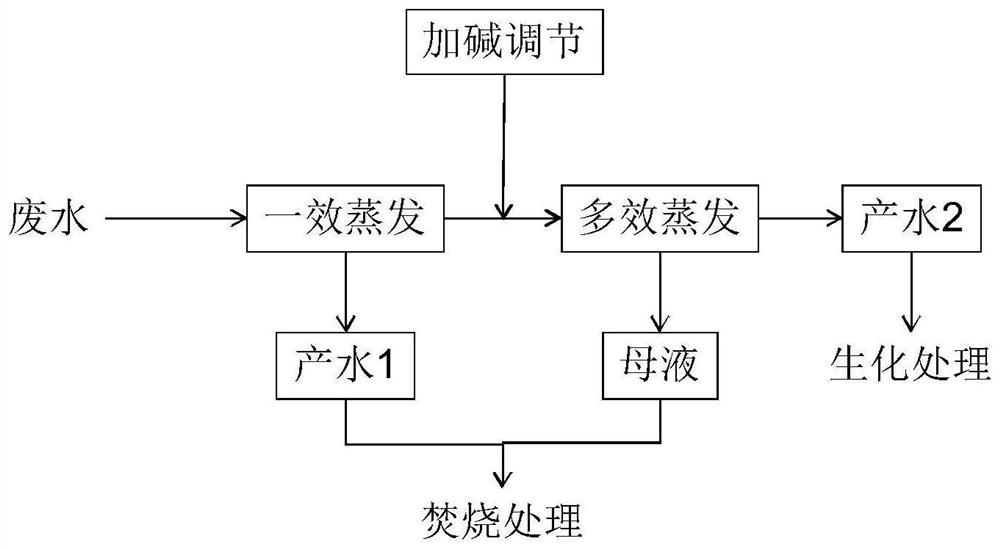

A technology for the production of wastewater and acrylates, applied in multi-stage water treatment, natural water treatment, heating water/sewage treatment, etc. problems, to achieve the effect of reducing the cost of incineration treatment, reducing the content of COD, and reducing the output of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The output of acrylate production process wastewater in a refinery in Guangdong is about 8m 3 / h, COD is 70000-120000mg / L, the original treatment process is incineration treatment technology, and the treatment cost per ton of water is 600-700 yuan, which is extremely high. At present, the company plans to upgrade the existing technology to reduce production and processing costs.

[0026] The wastewater treatment process for acrylate production of the present invention is used to reduce the amount of wastewater, wherein the multi-effect evaporation system is a three-effect evaporation treatment system. The raw water COD was measured to be 89000mg / L, and the raw water inflow was 7.5m 3 / h, the first-effect evaporation water production is 0.9m 3 / h, the COD measurement result of the produced water is 125000mg / L, the pH is adjusted to 8.7 by adding alkali, the amount of alkali added is 132kg / h, and the mother liquor output is 1m 3 / h, the production of water 2 is 5.5m 3...

Embodiment 2

[0028] The above-mentioned acrylate production process wastewater of a refinery in Guangdong was used as raw water. The raw water COD was measured as 97000mg / L, and the raw water inflow was 7.3m 3 / h, the first-effect evaporation water production is 0.8m 3 / h, the COD measurement result of the produced water is 143000mg / L, the pH is adjusted to 8.3 by adding alkali, the amount of alkali added is 136kg / h, and the mother liquor output is 0.8m 3 / h, the production of water 2 is 5.5m 3 / h, the COD content of the product water 2 is 2304mg / L, and the product water 2 enters the biochemical system for treatment.

Embodiment 3

[0030] The above-mentioned acrylate production process wastewater of a refinery in Guangdong was used as raw water. The raw water COD was measured as 125000mg / L, and the raw water inflow was 7.6m 3 / h, the first-effect evaporation water production is 0.8m 3 / h, the COD measurement result of the produced water is 164000mg / L, the pH is adjusted to 8.3 by adding alkali, the amount of alkali added is 143kg / h, and the mother liquor output is 0.8m 3 / h, the yield of product water 2 is 5.6m 3 / h, the COD content of the product water 2 is 2304mg / L, and the product water 2 enters the biochemical system for treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com