Garbage incinerator

A technology for waste incinerators and furnace bodies, which is applied to incinerators, combustion types, combustion methods, etc., can solve the problems of incomplete incineration of waste, unstable temperature in the furnace, and easily extinguished flames, so as to accelerate waste incineration efficiency, The effect of saving incineration cost and reducing labor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

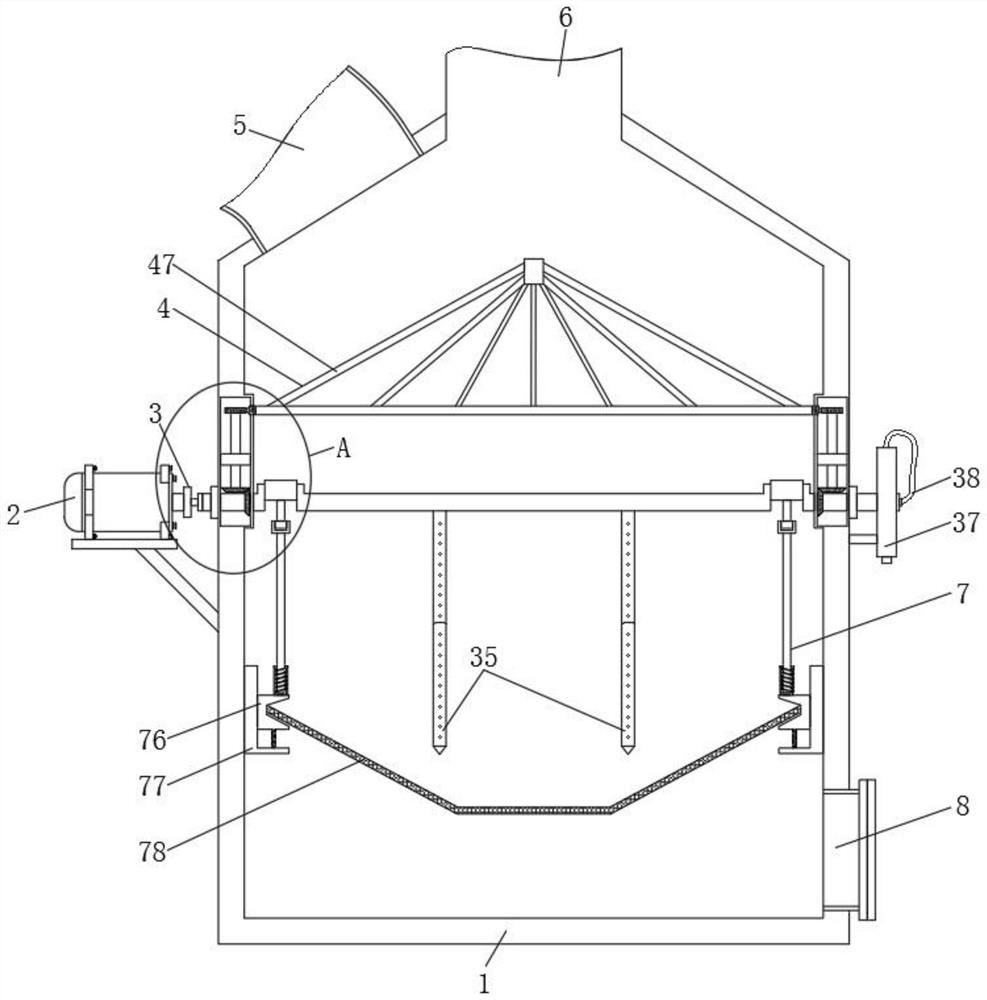

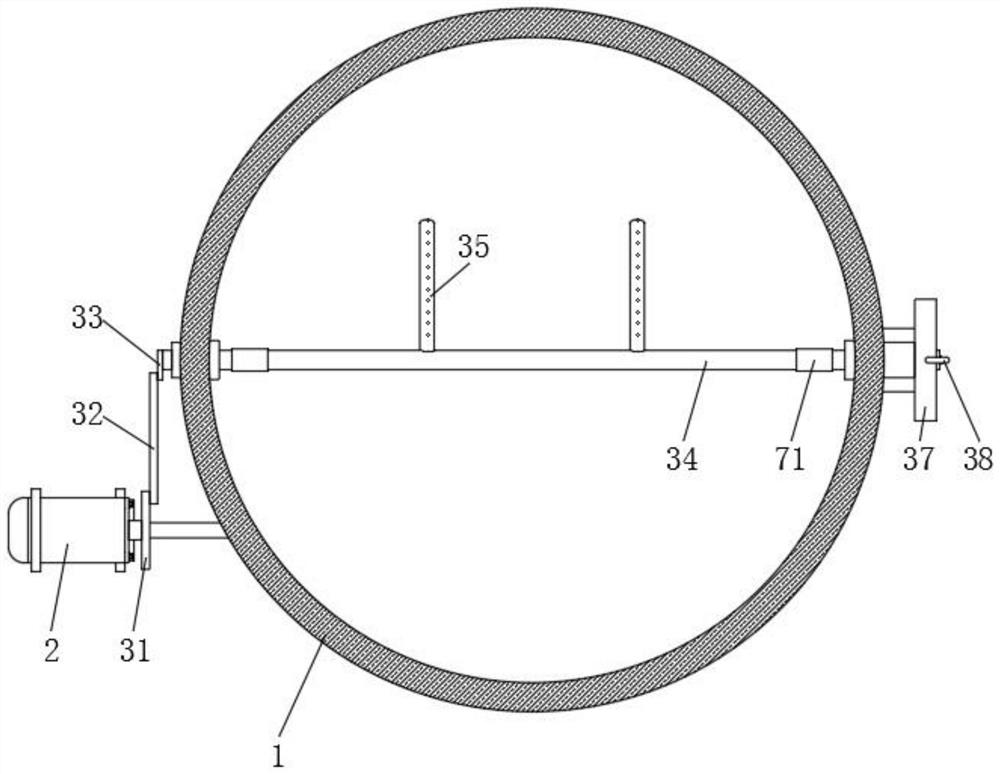

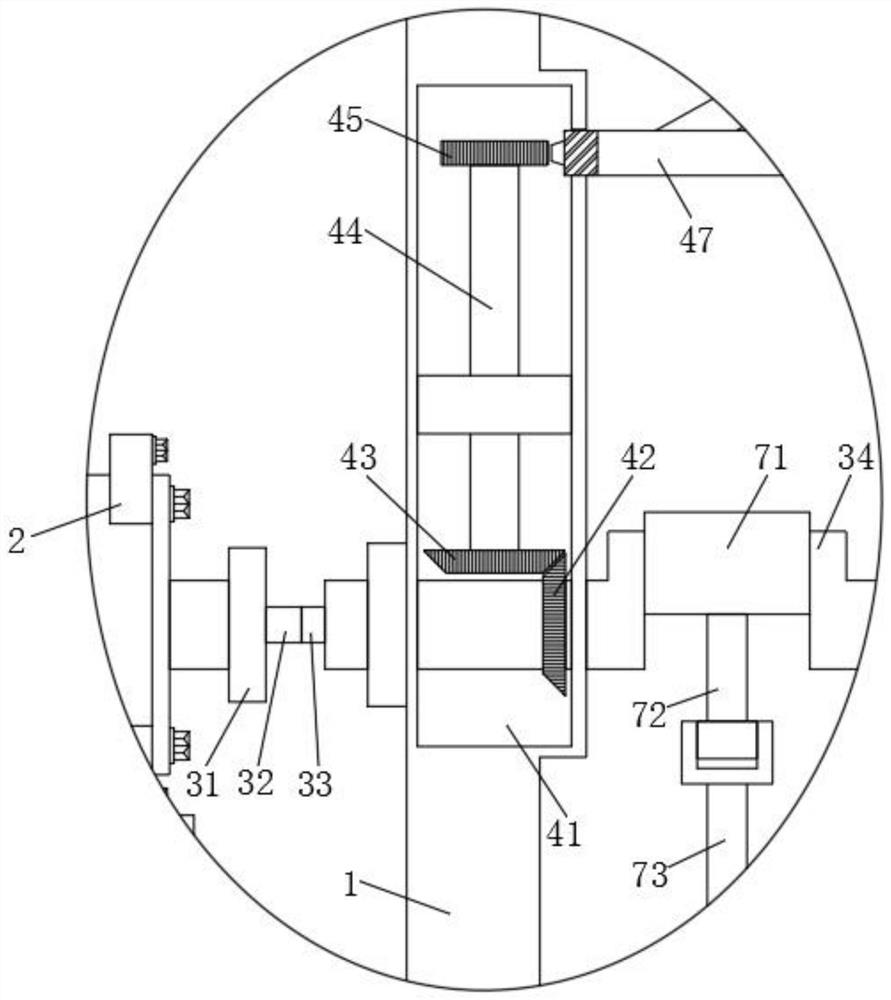

[0028] see Figure 1-3 , Figure 5-7 , a waste incinerator, comprising a furnace body 1, a motor 2 is fixedly installed in the middle position of the left side of the furnace body 1, a turning mechanism 3 is fixedly connected with the motor 2, and the turning mechanism 3 includes a turntable 31 fixedly connected with the motor 2, and the turntable 31 One side is rotatably connected with a connecting rod 32, one side of the connecting rod 32 is rotatably connected with a short rod 33, one side of the short rod 33 is fixedly connected with a rotating shaft 34, and the middle position of the rotating shaft 34 is fixedly connected with a turning rod 35, and the turning rod 35 is set as C The outer part of the right end of the rotating shaft 34 is sleeved with a fan blade 36, and the outer part of the fan blade 36 is provided with a sealing box 37, the sealing box 37 has air tightness, and the upper end of the sealing box 37 is inserted There is a trachea 38, the bottom end of the...

Embodiment 2

[0032] see Figure 1-7 , a waste incinerator, comprising a furnace body 1, a motor 2 is fixedly installed in the middle position of the left side of the furnace body 1, a turning mechanism 3 is fixedly connected with the motor 2, and the turning mechanism 3 includes a turntable 31 fixedly connected with the motor 2, and the turntable 31 One side is rotatably connected with a connecting rod 32, one side of the connecting rod 32 is rotatably connected with a short rod 33, one side of the short rod 33 is fixedly connected with a rotating shaft 34, and the middle position of the rotating shaft 34 is fixedly connected with a turning rod 35, and the turning rod 35 is set as C The outer part of the right end of the rotating shaft 34 is sleeved with a fan blade 36, and the outer part of the fan blade 36 is provided with a sealing box 37, the sealing box 37 has air tightness, and the upper end of the sealing box 37 is inserted There is a trachea 38, the bottom end of the trachea 38 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com