Garbage incinerator

A waste incinerator and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as insufficient internal combustion of waste, waste of resources, and reduce economic benefits of waste incineration, so as to reduce incineration costs and timely The effect of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

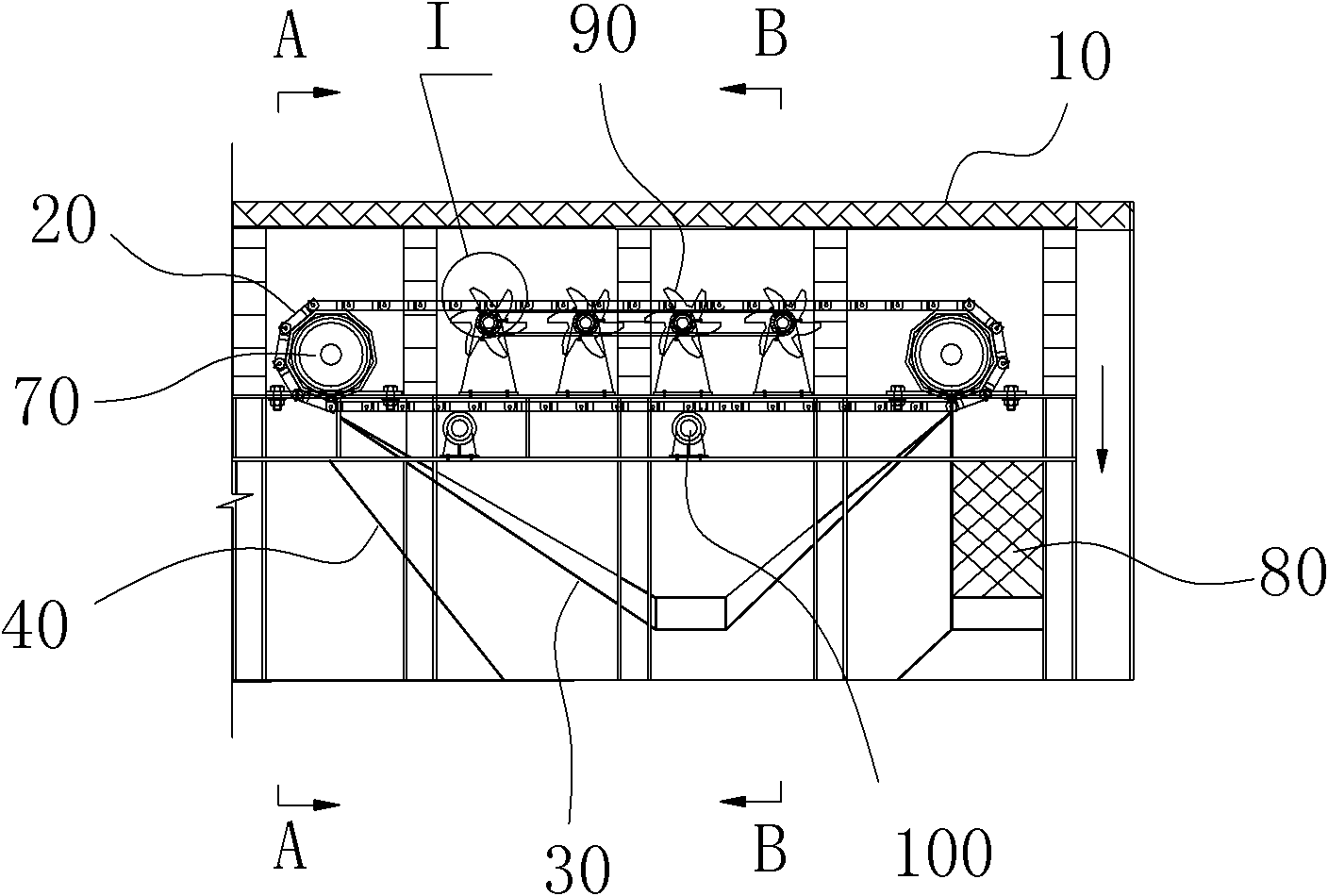

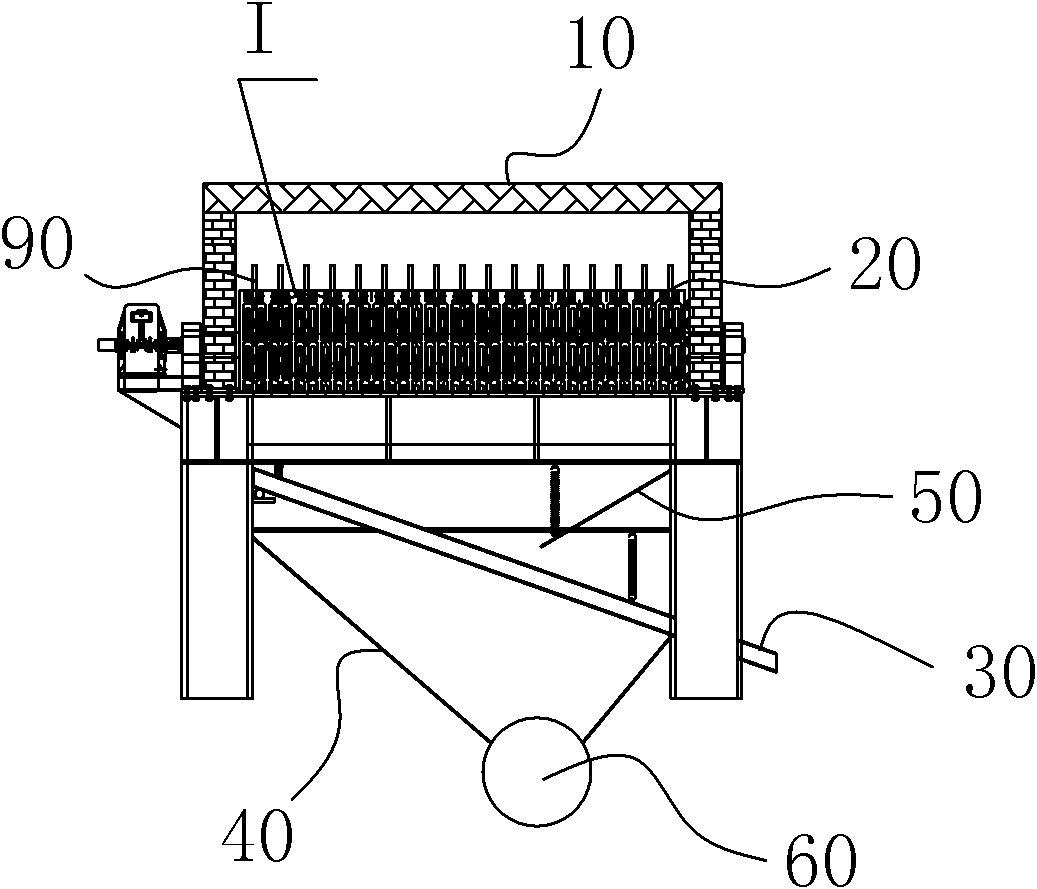

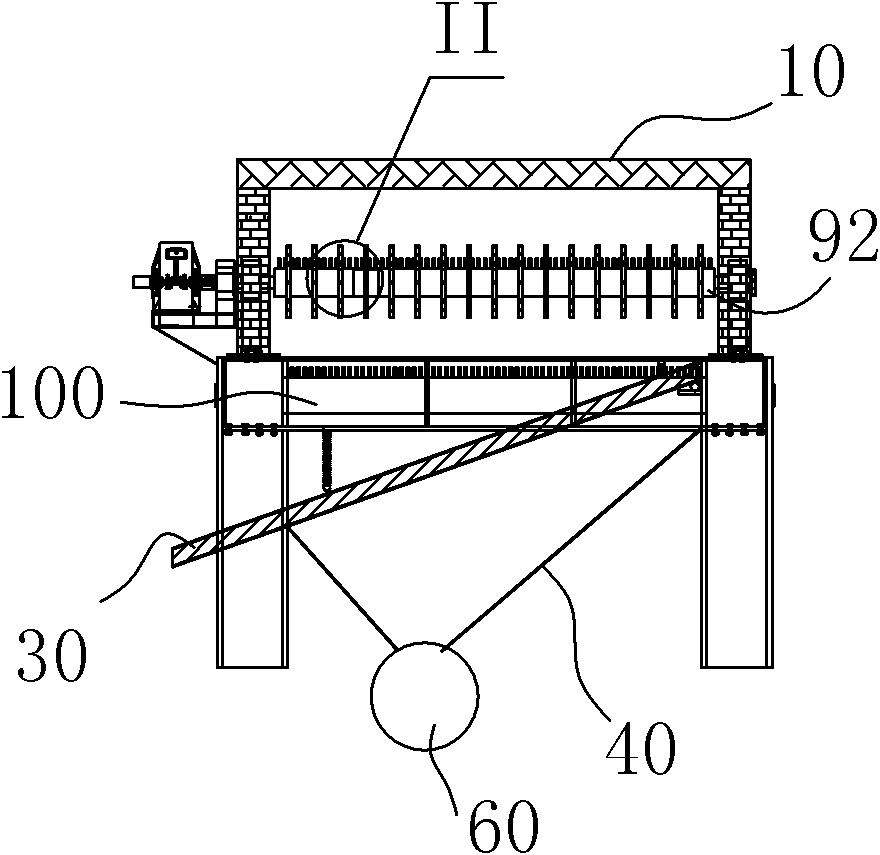

[0015] A garbage incinerator, comprising a furnace body 10 and an air duct, the incinerator also includes an incineration belt 20 for incinerating garbage, the incineration belt 20 is located inside the furnace body 10, and the incineration belt 20 is provided with a device for removing slag and ash. Falling structure, the underside of the incineration zone 20 is provided with a filter screen 30, such as Figure 1-3 shown.

[0016] As a further preferred solution of the present invention, the filter screen 30 can be a vibrating screen, such as Figure 2-3 , the filter screen 30 is in the shape of a plate mesh and is obliquely arranged in the furnace of the furnace body 10 , and a dust collecting funnel 40 is arranged below the filter screen 30 . In order to prevent the slag on the filter screen 30 from entering the ash collection funnel 40 , the lowest part of the plate mesh filter screen 30 extends beyond the upper funnel mouth of the ash collection funnel 40 .

[0017] lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com