High-strength compression dehydration garbage station

A garbage station, high-strength technology, applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of not particularly considerable economic benefits, achieve the effect of ingenious design, reduce incineration costs, and reduce freight costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

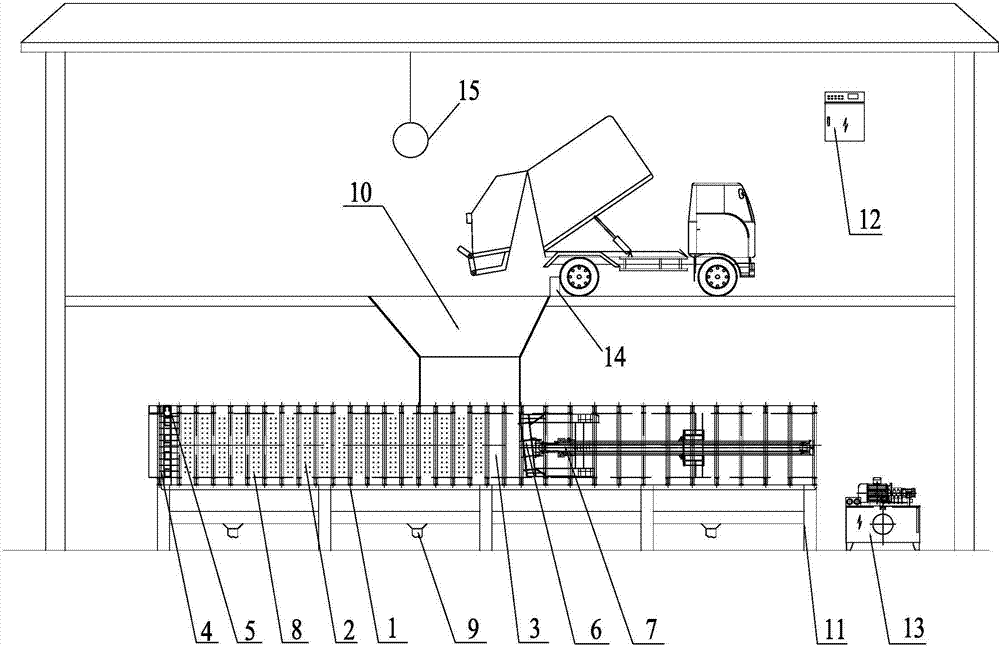

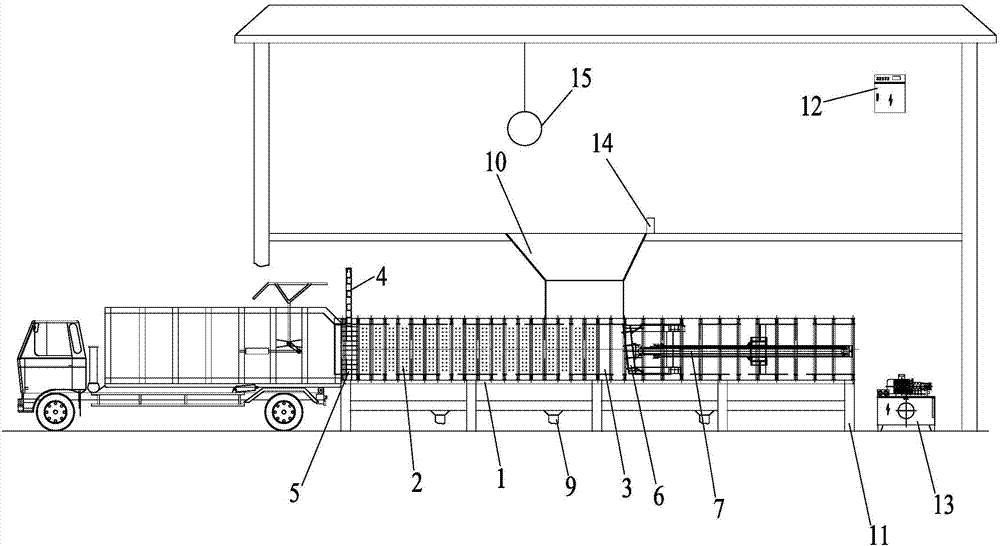

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] figure 1 , 2 Among them, it includes box body 1, compression chamber 2, garbage bin 3, front gate 4, front gate cylinder 5, push head 6, main cylinder 7, drainage channel 8, drainage pipe 9, garbage hopper 10, frame 11, Remote control room 12, hydraulic station 13, limit column 14, infrared probe 15, etc.

[0016] Such as figure 1 , 2 As shown, the present invention is a high-strength compression dehydration garbage station, including a frame 11 placed on the first floor of the garbage station, a box body 1 is arranged on the frame 11, and a compression chamber 2 communicating with each other is arranged on the box body 1 And the garbage bin 3, the top of the box body 1 is provided with a garbage bin 10, the garbage bin 10 is connected to the garbage bin 3, the push head 6 is arranged in the cavity of the box body 1, and the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com