Municipal sludge incinerating system using rubbish landfill gas as auxiliary fuel

A technology of landfill gas and municipal sludge, applied in the direction of combustion method, combustion type, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high cost of sludge incineration, multiple auxiliary fuels, etc., and reduce incineration treatment The cost and economic benefits are obvious, and the effect of improving incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

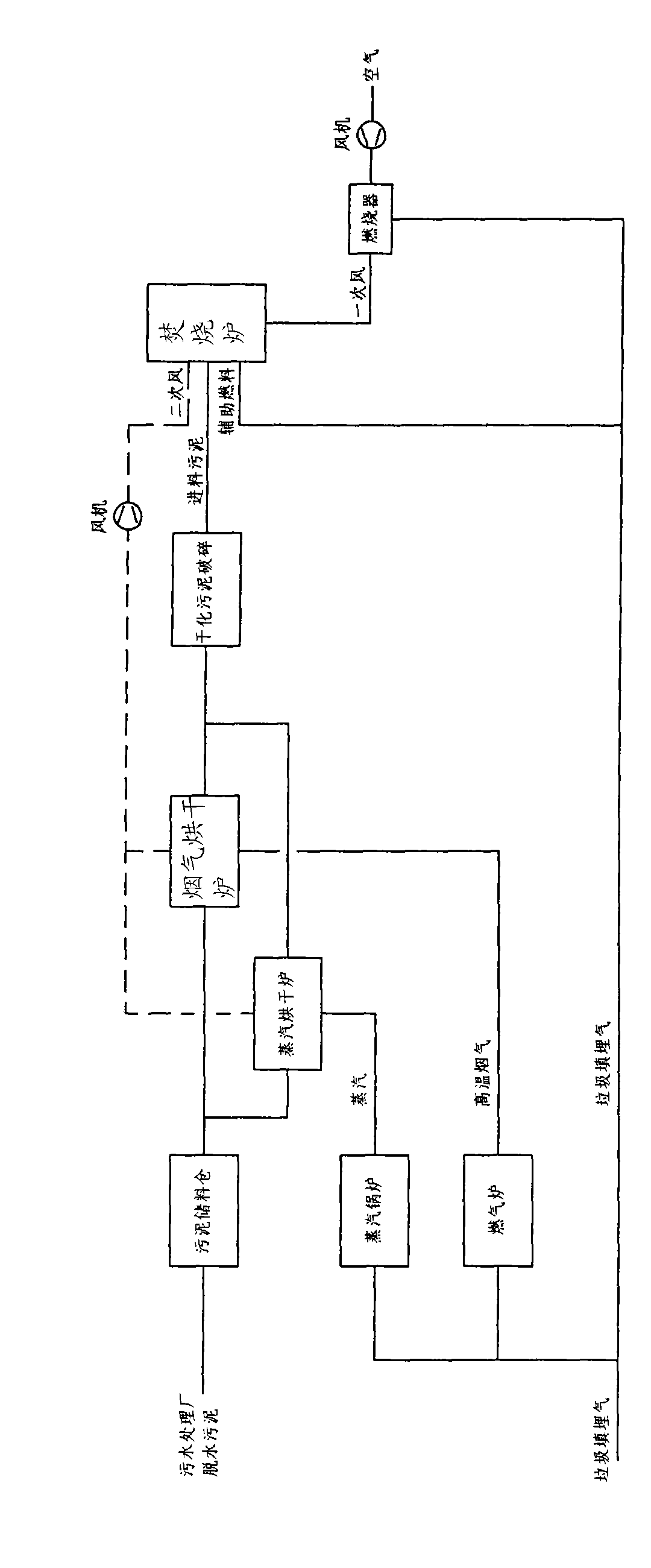

[0012] Such as figure 1 As shown, the municipal sludge with a water content lower than 90% after dehydration in the sewage treatment plant is stored in the sludge storage bin before being dried. Moisture content changes after rain. Municipal sludge is first dried. The thermal energy of the sludge drying equipment comes from landfill gas. The high-temperature steam generated by the steam boiler burning landfill gas can be used to dry the sludge. The steam pressure is 3-10 It can also use gas furnaces to burn landfill gas to generate high-temperature flue gas with a temperature between 220-300 ° C and use it to dry sludge. The exhaust gas produced in the steam drying furnace or flue gas drying furnace is extracted by a fan as the secondary air of the sludge incinerator to reduce the odor generated during the drying process. The moisture content of the dried sludge after dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com