Pulverized coal combustion method and device with function of capturing CO2

A pulverized coal combustion and functional technology, applied in heating devices, using non-combustion exothermic chemical reactions to generate heat, heating fuel, etc., can solve incomplete reaction between coal and oxygen carrier, low reaction rate, separation difficulties, etc. problems, achieve far-reaching social significance and economic value, reduce the level of CO2 concentration, and prevent a sharp increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

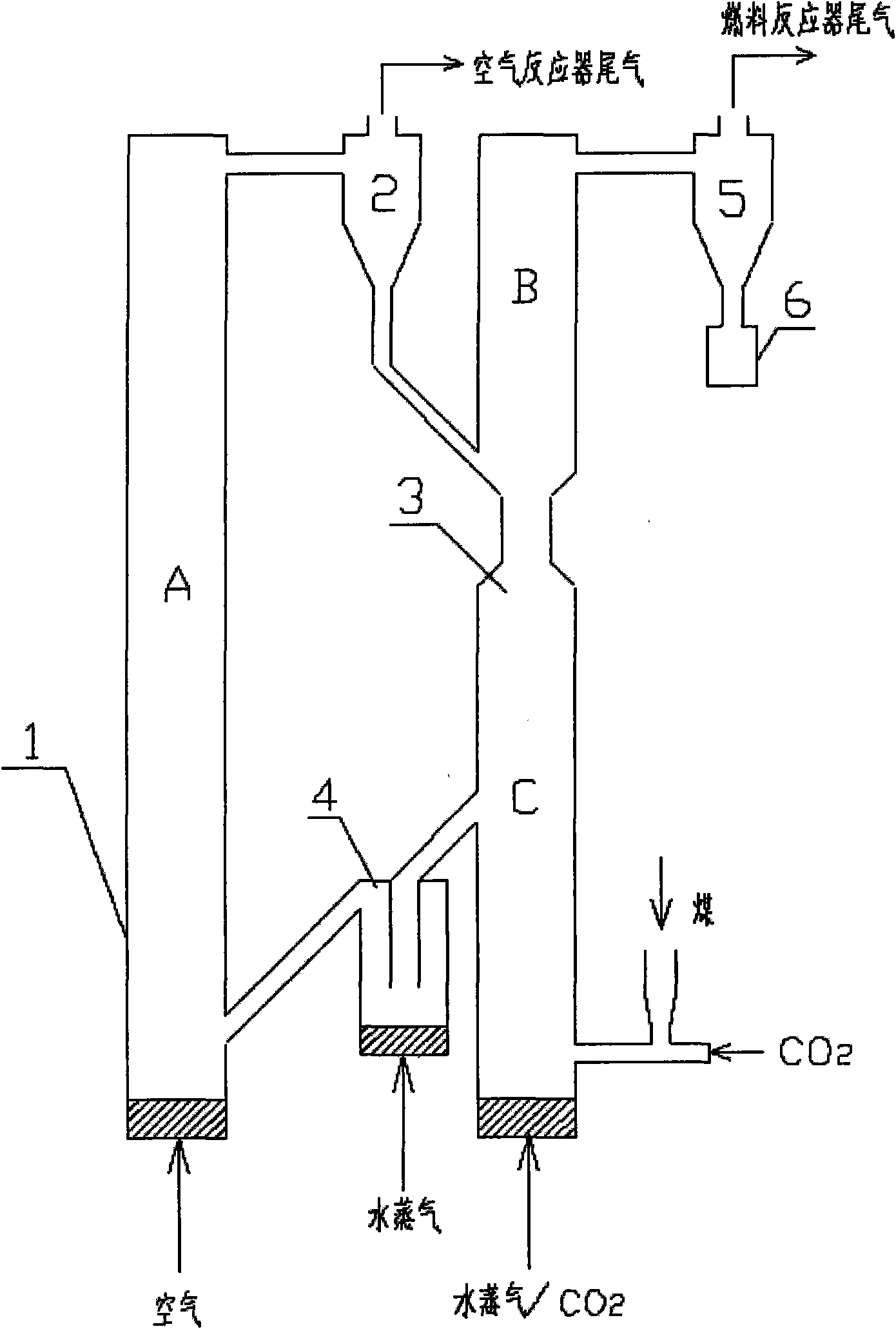

[0010] The present invention proposes to have CO 2 The new pulverized coal utilization device with capture function is composed of fast fluidized bed 1, first cyclone separator 2, bubbling fluidized bed 3, U-shaped flow sealing valve 4, second cyclone separator 5 and ash catcher 6. The upper part of the fast fluidized bed 1 communicates with the first cyclone separator 2, and the residual air of the reaction is discharged through the first separator 2, while the lower part of the first cyclone separator 2 communicates with the upper half of the bubbling fluidized bed 3 , the coal reaction tail gas is discharged through the second cyclone separator 5, the coal fly ash and fine oxygen carrier particles are collected through the ash catcher 6, and the lower half of the bubbling fluidized bed 3 is connected to the U-shaped flow sealing valve 4 connected, and then introduced into the fast fluidized bed 1 to complete the oxidation regeneration of the oxygen carrier and the subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com