Process for refining molten iron by directly using low-grade iron ores

A low-grade iron ore technology, applied in the direction of fluidized bed furnace, etc., can solve the problems of pollution, high energy consumption of molten iron smelting process, reduce cooling and heating, reduce raw material agglomeration process, save energy consumption and pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

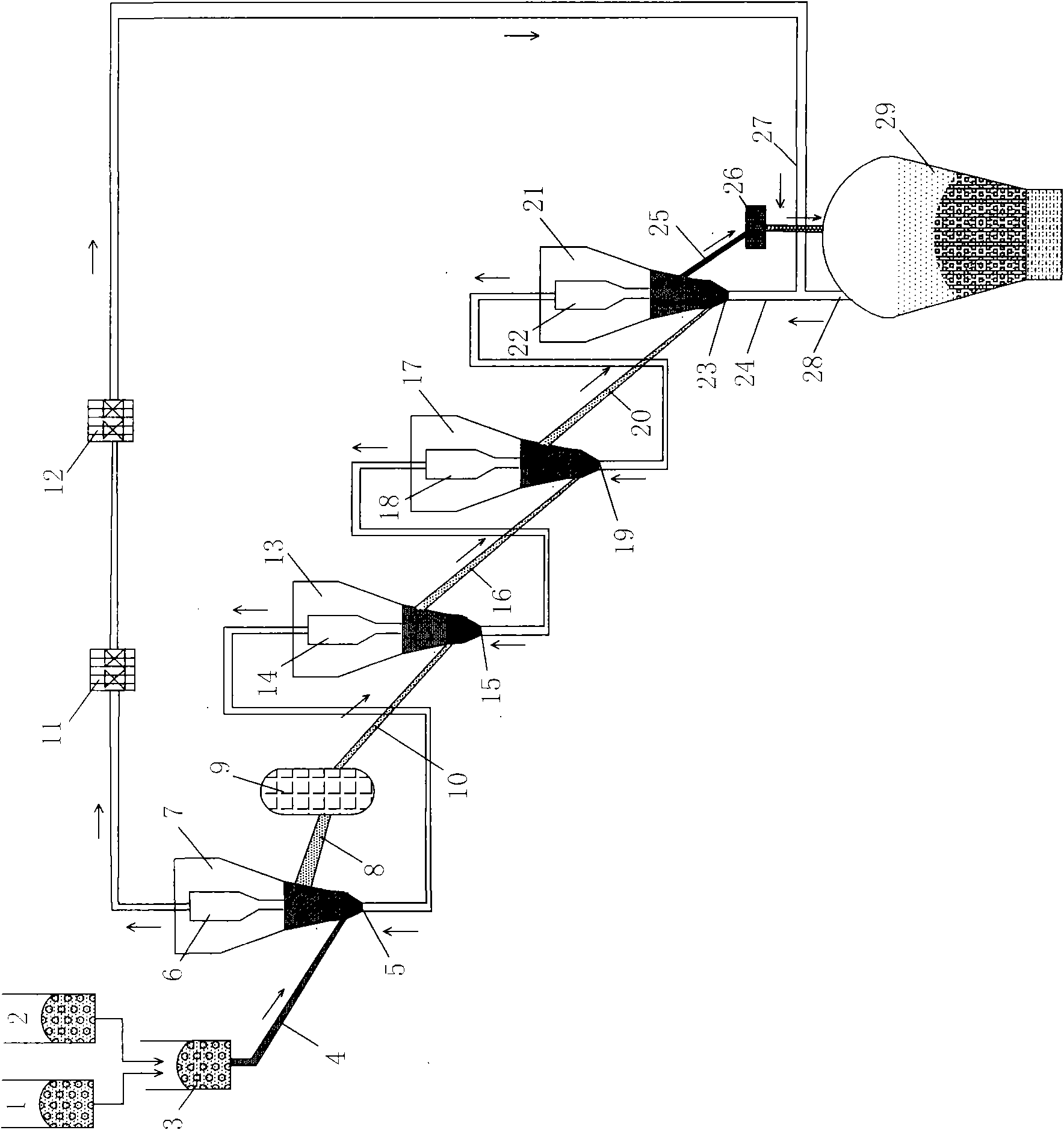

[0029] see figure 2 , fine iron ore 1, flux 2 are added to the lower part of the roasting fluidized bed 7 from the silo 3 through the feeding pipe 4, and the reducing gas enters the roasting fluidized bed 7 equipped with the hot cyclone separator 6 from the roasting fluidized bed inlet 5 , The inlet gas of the roasting fluidized bed is the outlet gas of the pre-reduction fluidized bed through the hot cyclone 14 . After the fine iron ore 1 is magnetized and roasted in the roasting fluidized bed 7, it is added to the thermal magnetic separator 9 through the feeding pipe 8, and the higher grade fine iron ore obtained by thermal magnetic separation enters the pre-reduction one through the feeding pipe 10. 13 in a fluidized bed. The inlet gas of the pre-reduction primary fluidized bed 13 enters through the gas inlet 15 of the pre-reduction primary fluidized bed, and the inlet gas is the reduction gas obtained by the outlet gas of the pre-reduction secondary fluidized bed 17 throu...

Embodiment 2

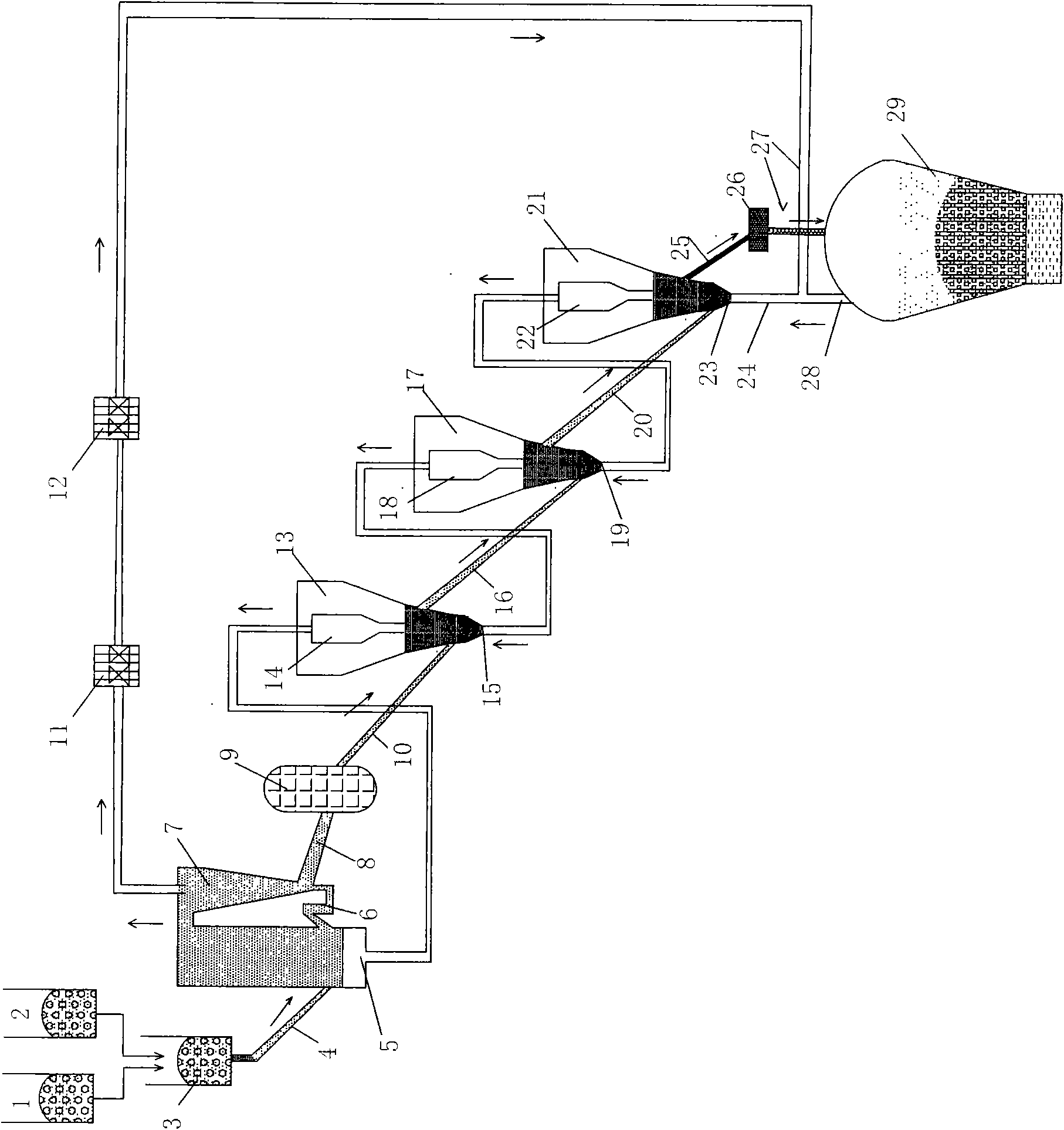

[0031] see image 3 , powder iron ore 1, flux 2 are added to the lower part of the roasting fluidized bed 5 from the feed bin 3 through the feeding pipe 4, and the reducing gas enters the roasting fluidized bed 7 from the roasting fluidized bed inlet 5, and the roasting fluidized bed 7 is equipped with The L-shaped return valve 6, the inlet gas of the roasting fluidized bed is the outlet gas of the pre-reduction fluidized bed through the hot cyclone 14. After the fine iron ore 1 is magnetized and roasted in the roasting fluidized bed 7, it is added to the thermal magnetic separator 9 through the feeding pipe 8, and the higher grade fine iron ore obtained by the thermal magnetic separation enters the heating equipment through the feeding pipe 10. The cyclone separator 14 is pre-reduced in the primary fluidized bed 13 . The inlet gas of the pre-reduction primary fluidized bed 13 enters through the gas inlet 15 of the pre-reduction primary fluidized bed, and the inlet gas is the...

Embodiment 3

[0034] see Figure 4 , fine iron ore 1, flux 2 are added to the lower part of the roasting fluidized bed 7 from the silo 3 through the feeding pipe 4, and the reducing gas enters the roasting fluidized bed 7 equipped with the hot cyclone separator 6 from the roasting fluidized bed inlet 5 , The inlet gas of the roasting fluidized bed is the outlet gas of the pre-reduction fluidized bed through the hot cyclone 14 . After the fine iron ore 1 is magnetized and roasted in the roasting fluidized bed 7, it is added to the thermal magnetic separator 9 through the feeding pipe 8, and the higher grade fine iron ore obtained by the thermal magnetic separation enters the heating equipment through the feeding pipe 10. The cyclone 14 is pre-reduced in the primary fluidized bed 13 . After being reduced in the pre-reduction primary fluidized bed 13, fine iron ore is added to the pre-reduction secondary fluidized bed 17 through the feed pipe 16, and the inlet gas of the pre-reduction primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com