Process for preparing sulfur dioxide by roasting troilite in circulating fluidized bed

A circulating fluidized bed and sulfur dioxide technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve problems such as low yield, increased air inhomogeneity, and limited output of a single machine, so as to increase the output of a single machine, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

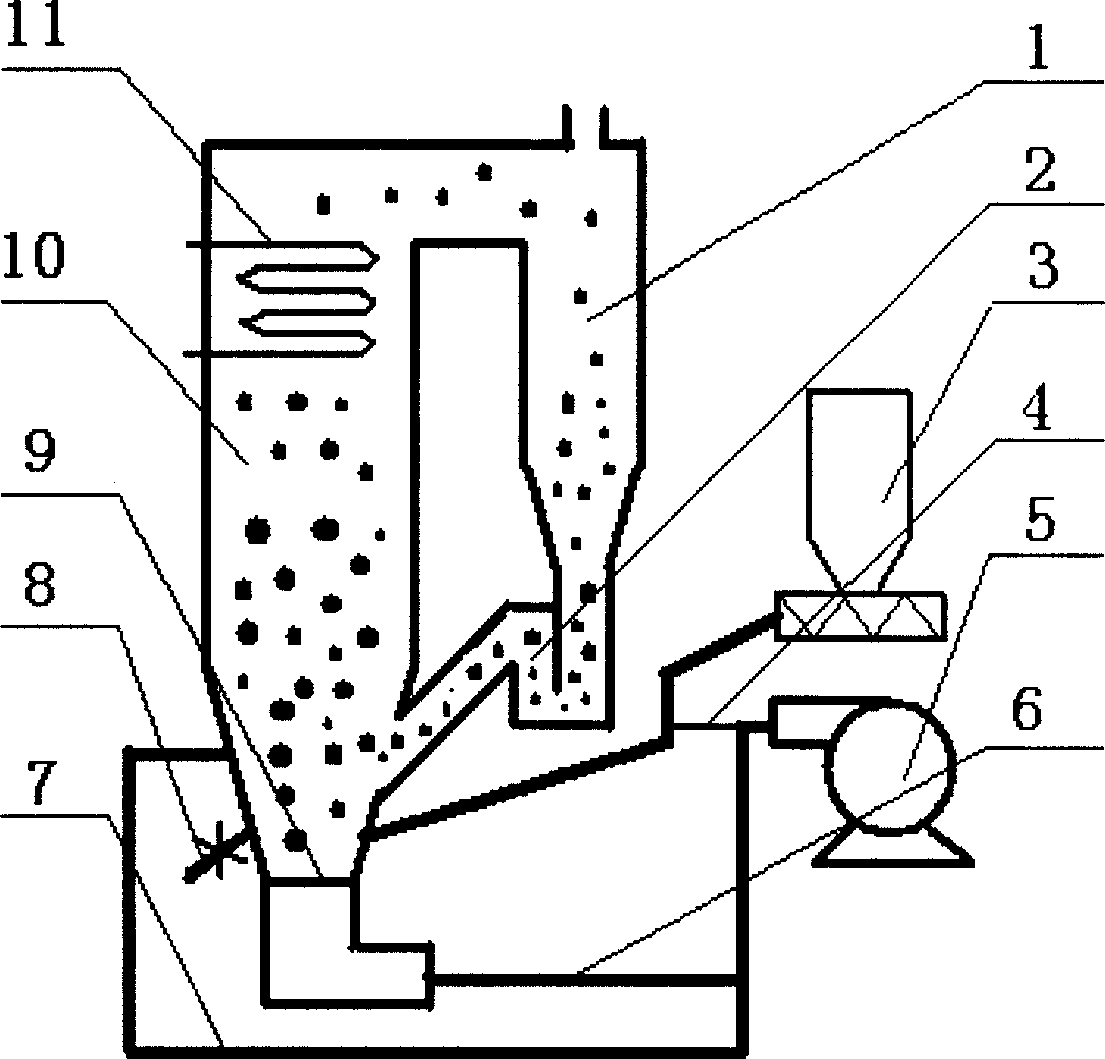

[0015] The process method of the present invention will be further explained below in conjunction with the accompanying drawings.

[0016] figure 1 It is a schematic structural diagram of an embodiment of a circulating fluidized bed device for roasting pyrite to prepare sulfur dioxide provided by the present invention. The device mainly includes a circulating fluidized bed reactor 10, a separation system 1, a feeding system 2, a feeding system 3, a slag discharge system 8, a fan 5, and an air distribution system 9 arranged outside the circulating fluidized bed reactor. Inside the circulating fluidized bed reactor, there is a built-in suspended screen heat balance system 11, and the heat balance system can also use an external bed heat exchanger or a membrane water wall heat exchanger. The separation system generally uses a cyclone separation device.

[0017] Firstly, ferric oxide with an average particle diameter of 40-50 microns is put into the circulating fluidized bed reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com