Industrial slag salt bubbling fluidized bed incineration harmless treatment device and method

A bubbling fluidized bed, harmless treatment technology, applied in combustion methods, incinerators, combustion types, etc., can solve problems such as pollution, waste of resources and the environment, and achieve the effect of flexible process means and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

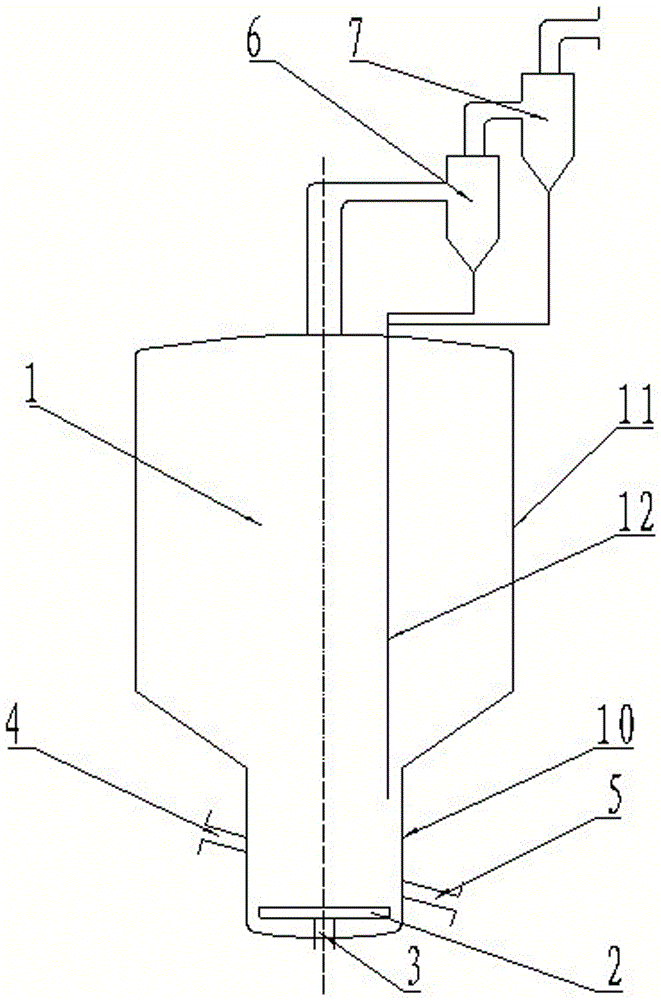

[0026] In the present embodiment, industrial slag salt is processed in batch mode, and its method comprises the following steps:

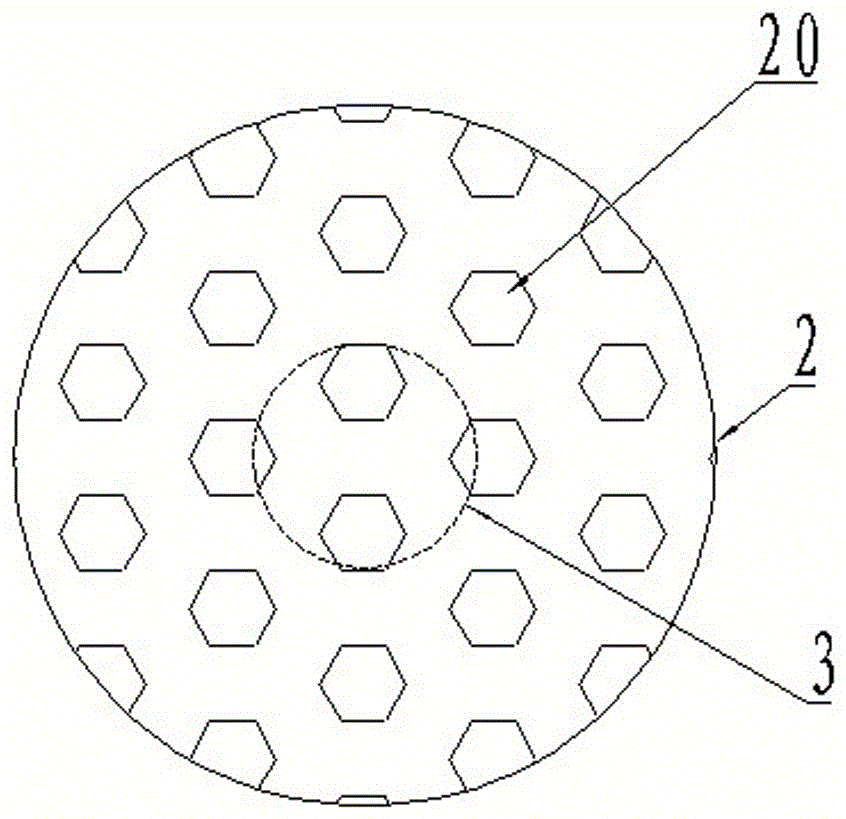

[0027] A. Introduce air and natural gas into the intake pipe 3, ignite, and continue burning after the gas is evenly distributed by the distribution plate 2; the temperature of the dense phase incineration zone 10 is controlled at 500-600 °C;

[0028] B, close the discharge pipe 5, import dry industrial slag salt from the feed pipe 4, and the particle size of the industrial slag salt is not more than 600 μm;

[0029] C, the recombination in the industrial slag salt is decomposed into light components and coke, the moisture in which is evaporated, and the organic matter and coke are burned;

[0030] D. The small particle size substances in the dense-phase incineration zone 10 are blown into the dilute-phase incineration zone 11, presenting a suspended state;

[0031] E. The tail gas is discharged through the top pipeline of the incinerator 1, and t...

Embodiment 2

[0034] In the present embodiment, industrial slag salt is processed in continuous operation mode, and its method comprises the following steps:

[0035] A. Introduce air and natural gas into the intake pipe 3, ignite, and continue burning after the gas is evenly distributed by the distribution plate 2; the temperature of the dense phase incineration zone 10 is controlled at 500-600 °C;

[0036] B. Continuously import dry industrial slag salt from the feed pipe 4, and the particle size of the industrial slag salt is not more than 600 μm;

[0037] C, the recombination in the industrial slag salt is decomposed into light components and coke, the moisture in which is evaporated, and the organic matter and coke are burned;

[0038] D. The small particle size substances in the dense-phase incineration zone 10 are blown into the dilute-phase incineration zone 11, presenting a suspended state;

[0039] E. The tail gas is discharged through the top pipeline of the incinerator 1, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com