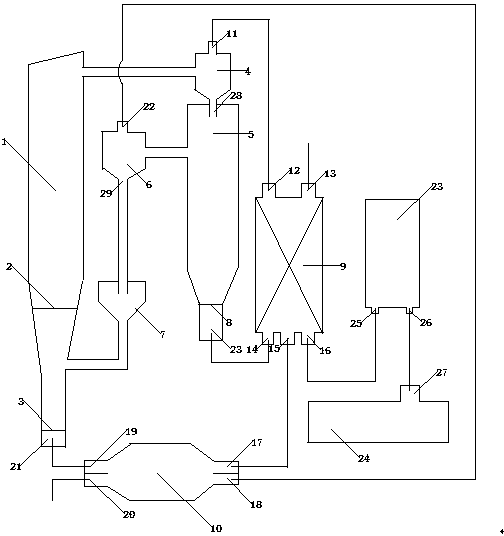

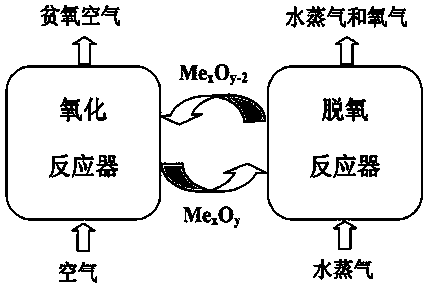

Device and method for preparing oxygen by virtue of chemical looping air separation

A technology of air separation and chemical chain, applied in oxygen preparation, chemical industry, climate sustainability, etc., can solve the problems of high cost, complicated operation, high energy consumption, etc., and achieve the effect of simple structure, easy operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The metal oxide oxygen carrier particle used is PbO 2 , the particle size of the particles is 100μm~200μm, the feed amount of oxygen carrier is 500g, the flow rate of water vapor entering the bubbling fluidized bed reactor is 5 L / min, and the reaction temperature in the bubbling fluidized bed reactor is The temperature is 250~350°C, the operating pressure is 0.1~0.2MPa, the reaction temperature of the fast bed reactor is 400~500°C, the air flow rate input from the gas inlet of the fast bed reactor is 1L / min, and the operating pressure is 0.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com