Method and device for zero emission of CO2 from burning coal

A zero-emission, CO2 technology, applied in the production of hydrogen, etc., can solve problems such as environmental hazards, cost and energy consumption, system complexity, etc., and achieve the effect of improving utilization and promoting full gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

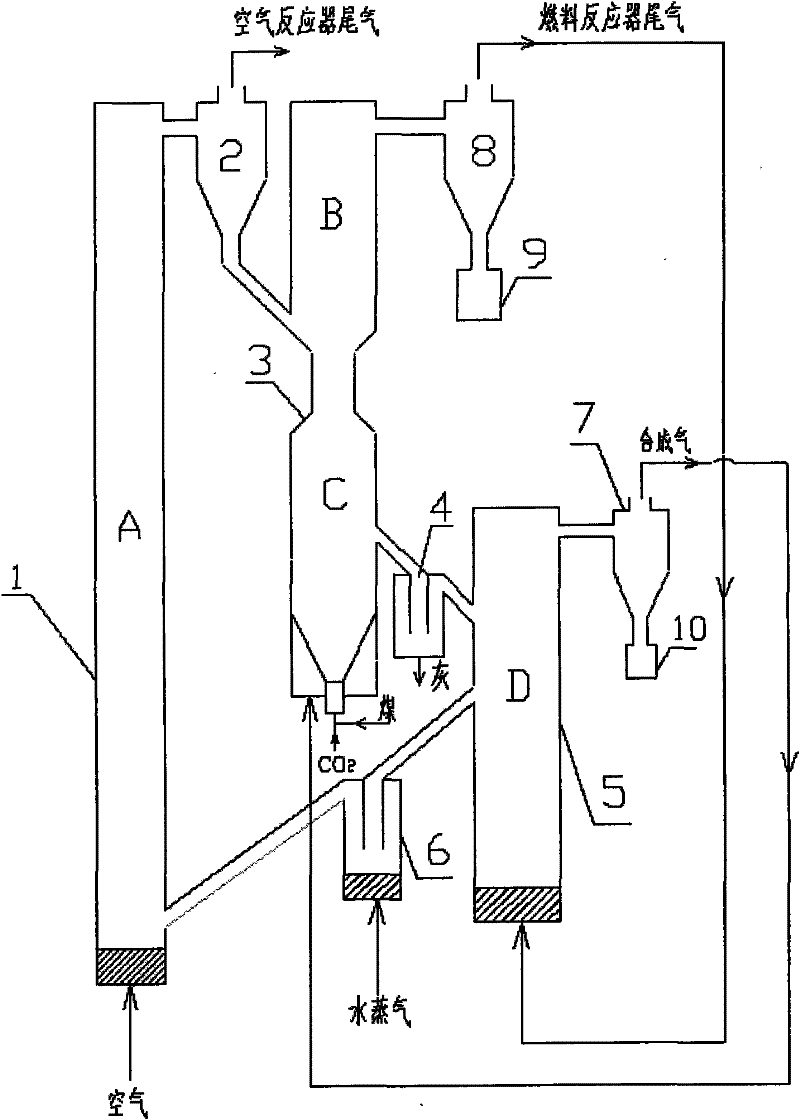

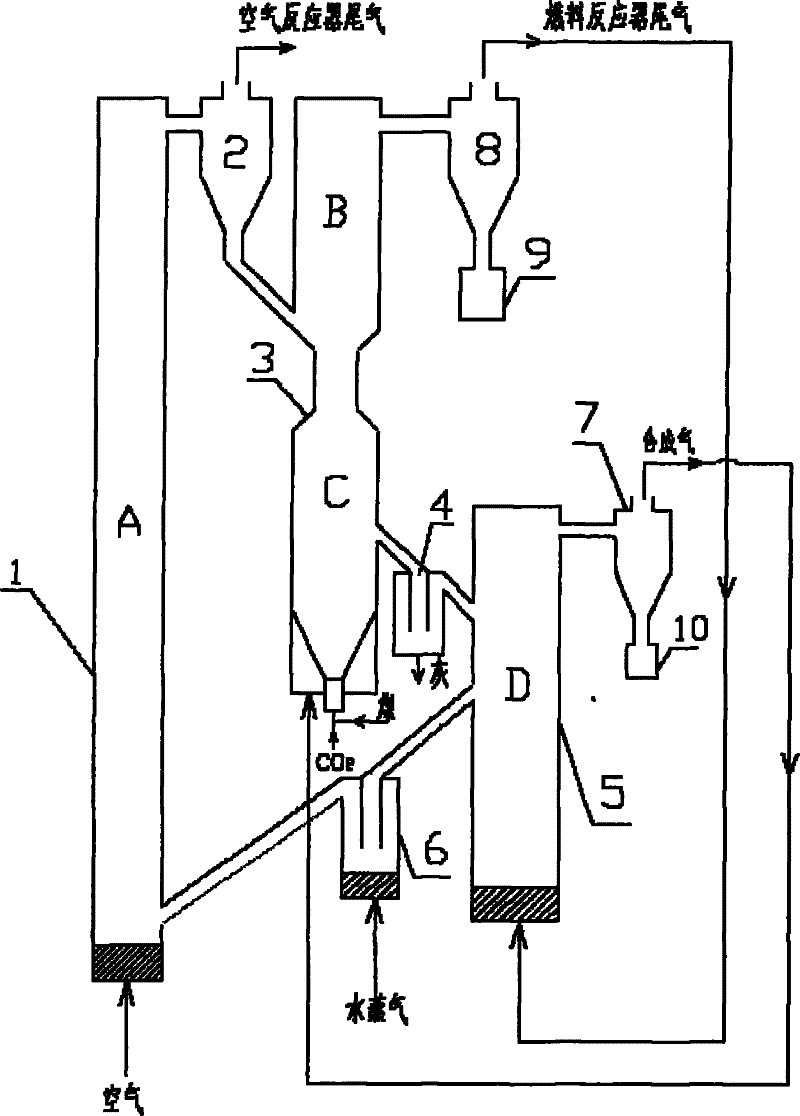

[0023] Coal CO proposed by the present invention 2 Zero emission devices such as figure 1 shown. One of the remarkable features of this device is the adoption of two-stage spouted fluidized bed, and the upper end of the lower fluidized bed and the lower end of the upper fluidized bed are respectively made into contraction port and expansion port type structures, not only It is beneficial to the organization of the flow field of the reaction flow in the fluidized bed, and it is also conducive to the strong back-mixing and prolongation of the residence time of the pulverized coal particles, the reaction gas flow and the oxygen carrier particles in the reactor.

[0024] Coal CO proposed by the present invention 2 Zero Emission Technology to MFe 2 o 4 (M stands for Cu, Mn, Co and Ni) is the oxygen carrier, which is transported into the upper section of the two-stage spouted fluidized bed 3 by the cyclone separator 2, and the oxygen carrier MFe is completed in the B area and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com