Flying ash processing device of fluidized bed incinerator

A treatment device and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of reducing the concentration of pollutants, the impact of cement clinker strength, and reducing the amount of fly ash emissions, so as to improve thermal economy performance, realize resource utilization, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

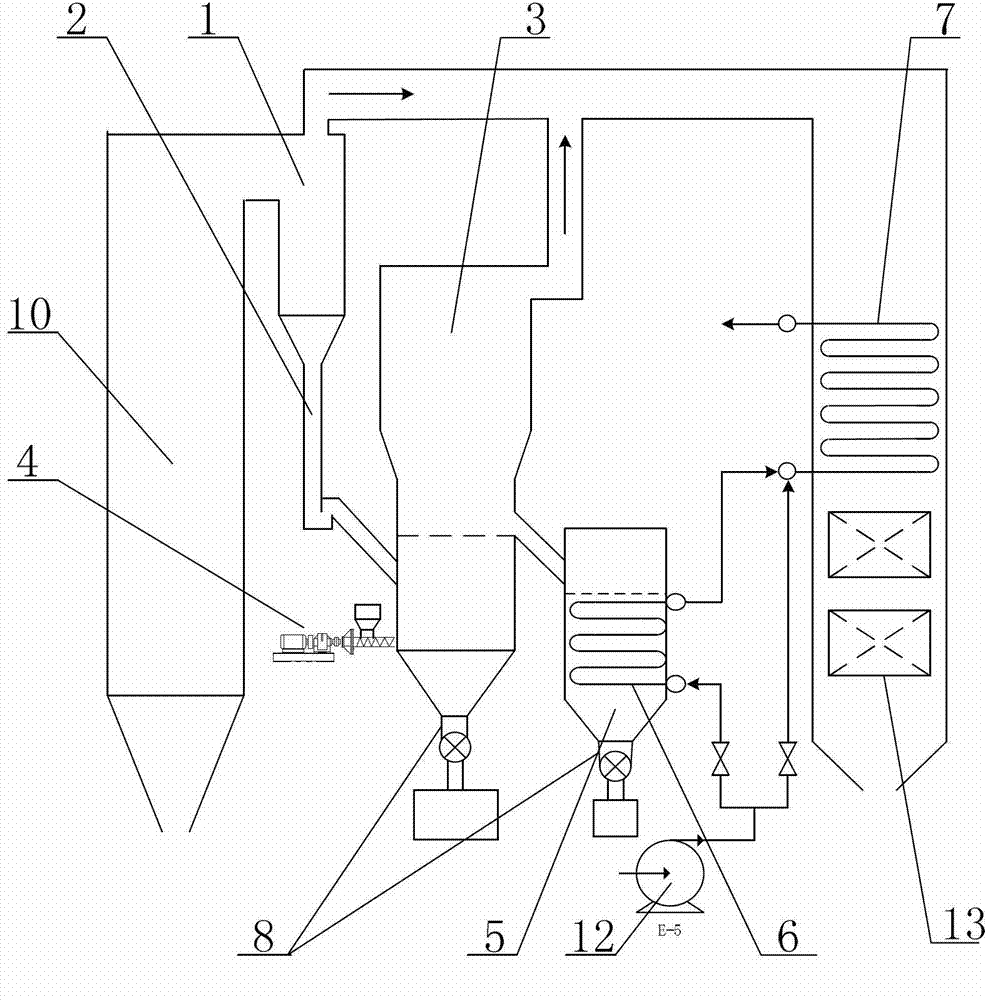

[0029] Example 1: figure 1 It is a structural schematic diagram of the fly ash treatment device of the bubbling fluidized bed incinerator according to the present invention.

[0030] Such as figure 1 Shown: Fly ash treatment device for a bubbling fluidized bed incinerator (garbage incineration) in a factory, including cyclone separator 1 (high-temperature and high-efficiency cyclone separator), fly ash conveying system 2, and bubbling fluidized bed device 3 and moving bed ash cooler 5, the cyclone separator 1 is arranged between the bubbling fluidized bed incinerator 10 and the tail flue, specifically: the cyclone separator 1 is arranged in the bubbling fluidized bed The furnace outlet of the incinerator 10, in addition, the cyclone separator 1 communicates with the bubbling fluidized bed device 3 through the fly ash conveying system 2 at the same time, and the moving bed ash cooler 5 is set in the bubbling flow The overflow port on the side of the fluidized bed device 3 com...

Embodiment 2

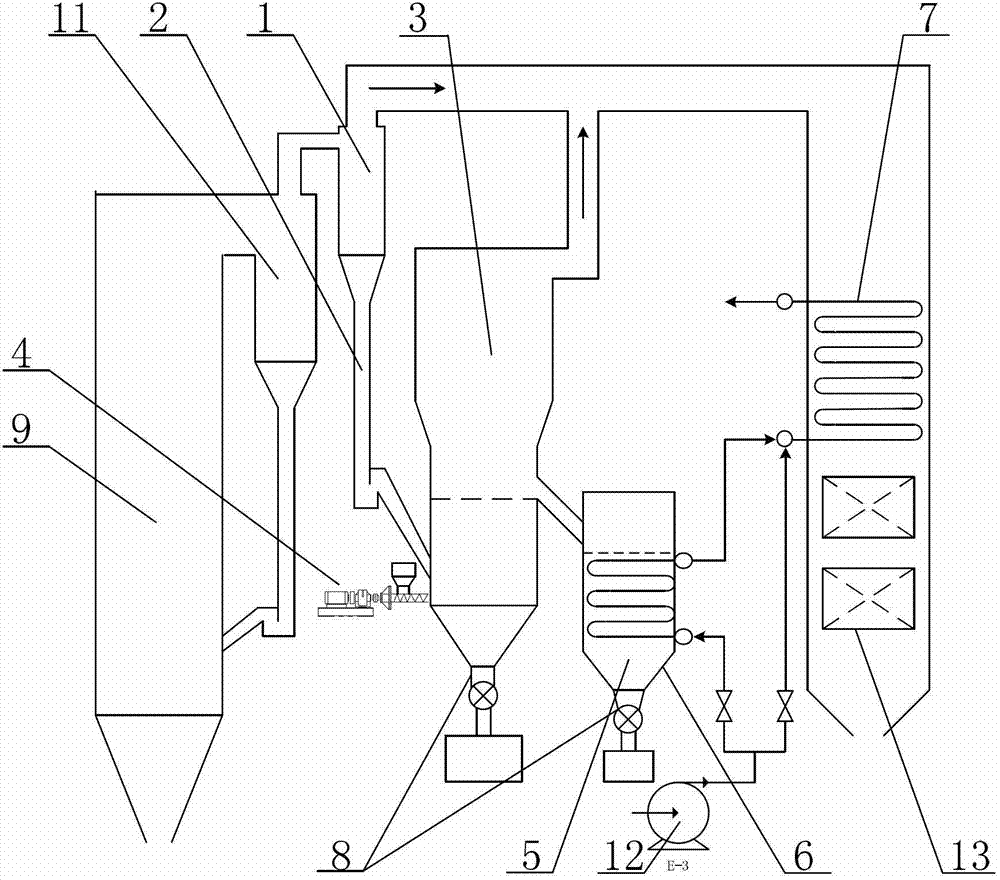

[0036] Example 2: figure 2 It is a structural schematic diagram of the fly ash treatment device of the circulating fluidized bed incinerator according to the present invention.

[0037] like figure 2 As shown: the structure of the fly ash treatment device for a 75t / h circulating fluidized bed incinerator 9 in a certain power plant is basically the same as the fly ash treatment device for a bubbling fluidized bed incinerator 10, the difference is that when the flow When the fluidized bed incinerator is a circulating fluidized bed incinerator 9, the cyclone separator 1 is arranged at the outlet of the cyclone separator 11 of the circulating fluidized bed incinerator. Since the other structures are completely identical, no further details are given.

[0038] In addition, the fly ash treatment process of the circulating fluidized bed incinerator 9 described in this embodiment is basically the same as the fly ash treatment process of the bubbling fluidized bed incinerator 10 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com