Apparatus for preparing synthetic gas with adjustable H2/CO proportion by methane-rich gas and method thereof

A synthesis gas and methane gas technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of increasing construction investment and operating costs, poor control of the ratio, etc., to avoid CO2 separation Steps, the effect of reducing construction input and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

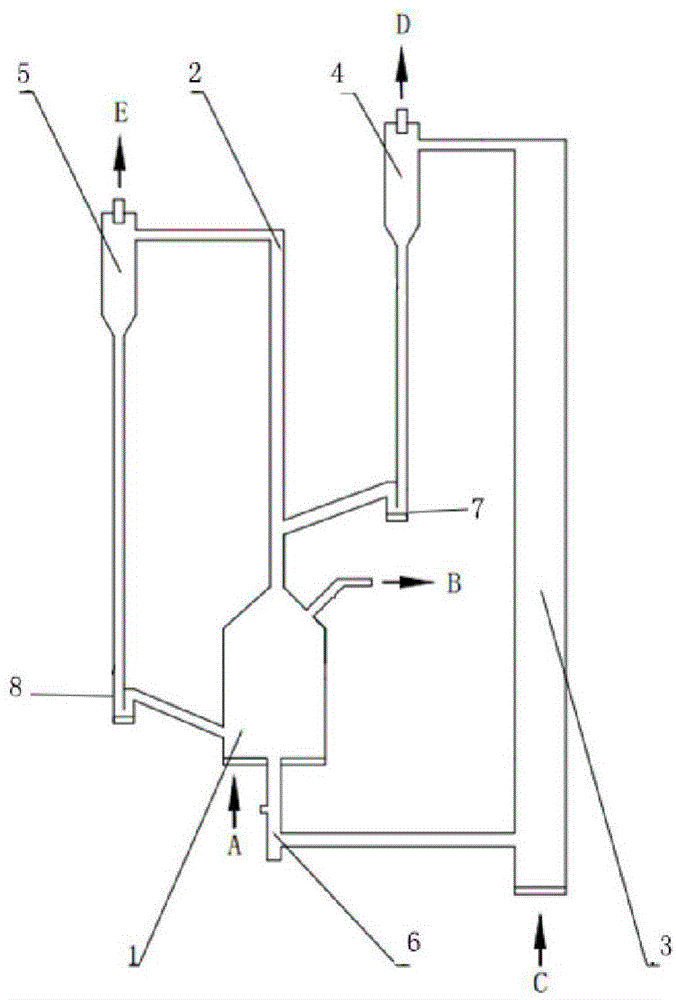

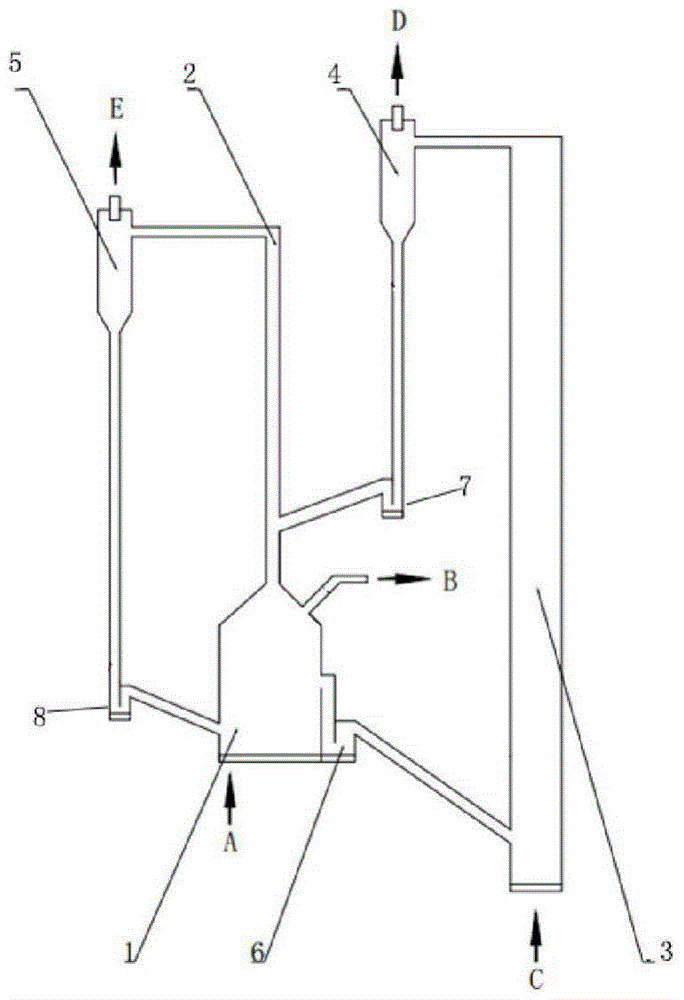

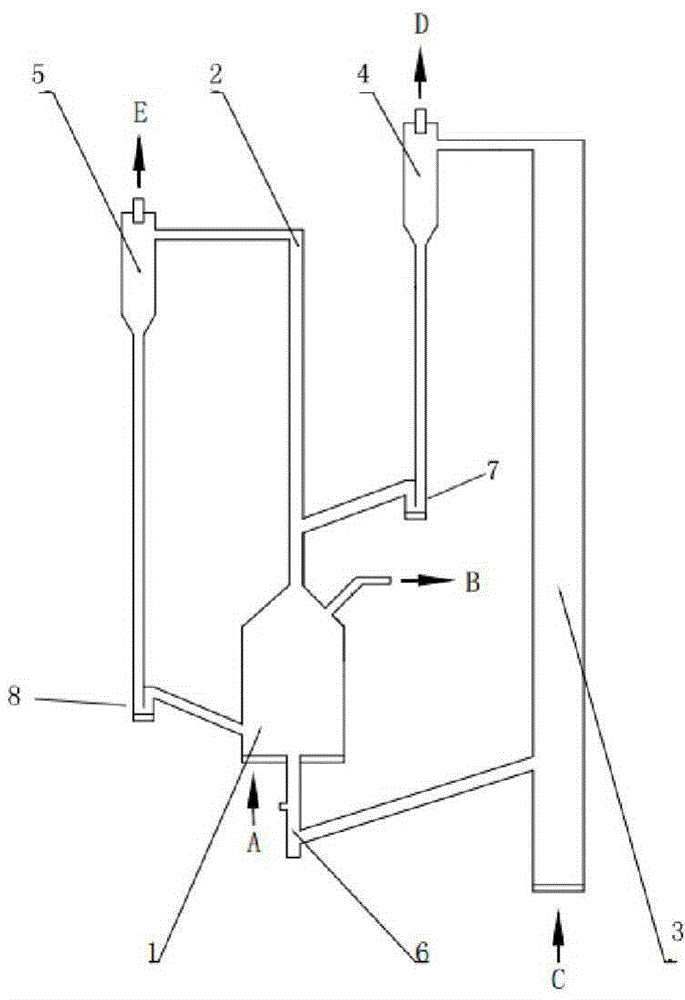

[0030] A methane-rich gas to produce H 2 / CO ratio adjustable syngas plant, such as Figure 1-3 As shown, it includes a fuel reactor, an air reactor 3, a first cyclone separator 4, a second cyclone separator 5, a return valve one 6, a return valve two 7, and a return valve three 8; the fuel reactor The lower part is the bubbling fluidized bed 1, and the upper part is the riser 2; the bubbling fluidized bed 1 is connected with the air reactor 3 through the return valve 6, and the upper part of the air reactor 3 is connected with the first cyclone separator 4, and the first The feeding pipe of the cyclone separator 4 is connected to the riser pipe 2 through the return valve 2 7, the upper part of the riser pipe 2 is connected to the second cyclone separator 5, and the feeding pipe of the second cyclone separator 5 passes through the return valve 3 8 and the drum The lower part of the bubble fluidized bed 1 is connected. Wherein, the return valve-6 can be an L-type return valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com