A method for manufacturing the whole hole of steel main girder of large composite beam

A manufacturing method and technology for steel main beams, which are applied in the directions of bridges, bridge materials, bridge construction, etc., can solve the problems of increasing the difficulty of controlling the alignment of steel beams, prolonging the construction period, increasing the manufacturing cost, etc., and achieving the control of the manufacturing alignment and the manufacturing accuracy. , Reduce the hidden dangers of safety, and make the line shape easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

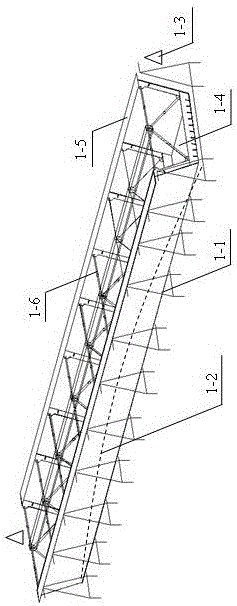

[0011] Embodiment 1: with reference to attached figure 1 . A large-scale combined steel main girder assembly tire frame system, including the steel main beam assembly tire frame and a measurement system, the assembly tire frame 1-1 is composed of a plurality of steel frames arranged vertically in a line, and the linear shape 1-2 constitutes the steel main girder vertical curve, and set the longitudinal measurement reference point 1-3 at the end of the frame.

[0012] figure 1 The overall schematic diagram made for the composite girder steel main girder, 1-1 indicates the total tire frame, which is used to control the outline size of the steel main girder, and 1-2 indicates the vertical alignment of the tire frame, which is used to control the linear arching of the steel main girder , 1-3 represent the longitudinal measurement points, which are used to measure the straightness of the steel girder.

Embodiment 2

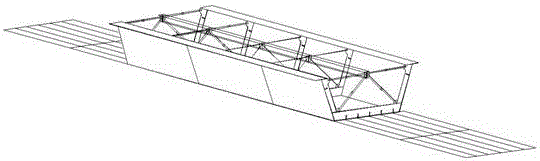

[0013] Embodiment 2: A large-scale composite girder steel girder composed of steel components, two steel girder web units 1-5 and one steel girder floor unit 1-4 form a channel-shaped steel girder, and multiple steel girders The three sides of the partition unit 1-6 are respectively welded to the inner wall of the channel-shaped steel main beam to form the steel main beam. The multi-steel girders are welded and connected to form a large-segment steel girder, and the bottom plate units 1-4 of the steel girder are vertical curves.

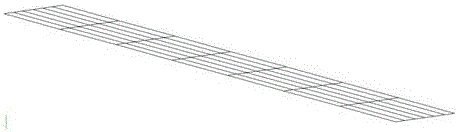

[0014] 1-4 represent the steel main girder bottom plate unit, 1-5 represent the steel main girder web plate unit, 1-6 represent the steel main girder diaphragm unit; Figure 2 is a schematic diagram of the steel main girder's whole hole manufacturing process, and state 2-1 represents the bottom plate Unit group welding process, state 2-2a represents the manufacturing process of the segmental steel main girder, state 2-2b represents the process of lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com