Chemical chain combustion method for coalbed methane, and interconnected fluidized bed system

A technology of chemical chain combustion and coalbed methane, which is applied in combustion methods, fluidized bed combustion equipment, and fuels burned in a molten state, can solve the problems of carbon deposition, oxygen-carrying carbon, increase costs, etc., and achieve good photodegradation performance. , The effect of reducing the formation of carbon deposits and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

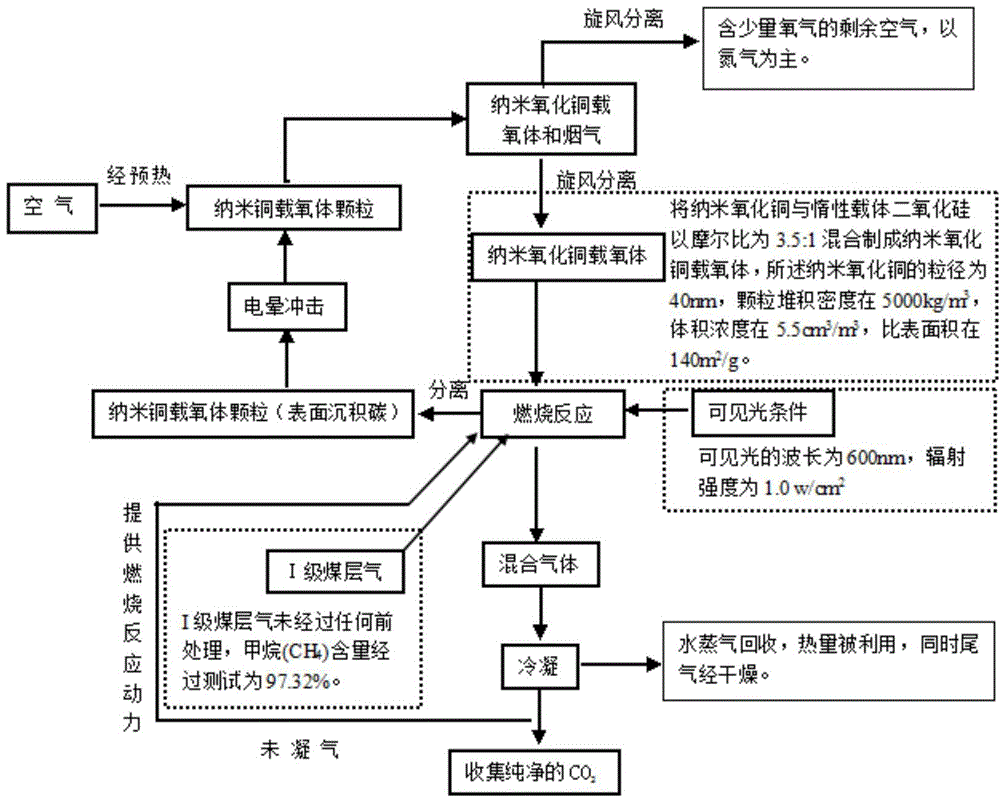

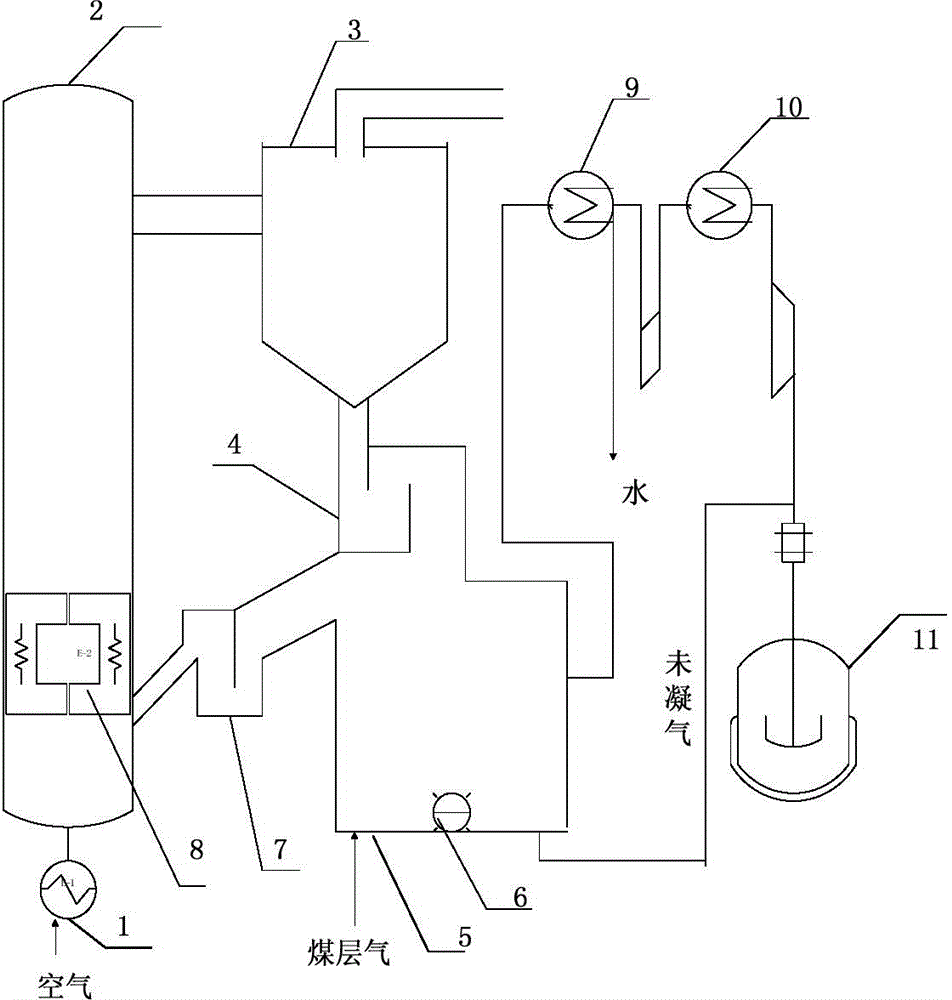

[0070] The chemical looping combustion method of coalbed methane comprises the following steps:

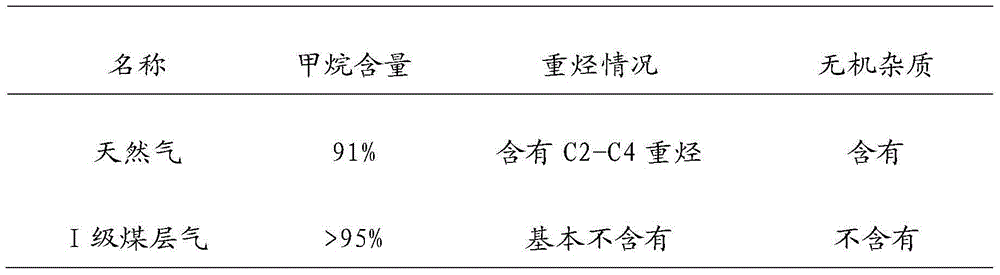

[0071] Step 1: Mix nano-copper oxide and inert carrier silica at a molar ratio of 1.5:1 to make nano-copper oxide oxygen carrier, the particle size of the nano-copper oxide is 20nm, and the particle packing density is 4500kg / m 3 , the volume concentration is 5cm 3 / m 3 , the specific surface area is 130m 2 / g. Oxidize the preheated air with the nano-copper oxygen carrier to generate nano-copper oxide oxygen carrier particles and flue gas;

[0072] The second step: separation of nano-copper oxide oxygen carrier particles and flue gas;

[0073] Step 3: Combust the separated nano-copper oxide oxygen carrier particles with Class I coalbed methane in a vacuum-enclosed environment and visible light to generate mixed gas and nano-copper oxygen carrier particles; the wavelength of visible light is 420nm , the radiation intensity is 0.5w / cm 2 ; Class I coalbed methane has not undergo...

Embodiment 2

[0078] The chemical looping combustion method of coalbed methane comprises the following steps:

[0079] Step 1: Mix nano-copper oxide and inert carrier silica at a molar ratio of 3.5:1 to make nano-copper oxide oxygen carrier, the particle size of the nano-copper oxide is 40nm, and the particle packing density is 5000kg / m 3 , the volume concentration is 5.5cm 3 / m 3 , the specific surface area is 140m 2 / g. Oxidize the preheated air with the nano-copper oxygen carrier to generate nano-copper oxide oxygen carrier particles and flue gas;

[0080] The second step: separation of nano-copper oxide oxygen carrier particles and flue gas;

[0081]Step 3: Combust the separated nano-copper oxide oxygen carrier particles with Class I coalbed methane in a vacuum-enclosed environment and visible light to generate mixed gas and nano-copper oxygen carrier particles; the wavelength of visible light is 700nm , the radiation intensity is 1.0w / cm 2 ; Class I coalbed methane has not underg...

Embodiment 3

[0086] The chemical looping combustion method of coalbed methane comprises the following steps:

[0087] Step 1: Mix nano-copper oxide and inert carrier silica at a molar ratio of 2.5:1 to make nano-copper oxide oxygen carrier, the particle size of the nano-copper oxide is 30nm, and the particle packing density is 4800kg / m 3 , the volume concentration is 5.2cm 3 / m 3 , the specific surface area is 135m 2 / g. Oxidize the preheated air with the nano-copper oxygen carrier to generate nano-copper oxide oxygen carrier particles and flue gas;

[0088] The second step: separation of nano-copper oxide oxygen carrier particles and flue gas;

[0089] Step 3: Combust the separated nano-copper oxide oxygen-carrier particles with Class I coalbed methane in a vacuum-enclosed environment and visible light to generate mixed gas and nano-copper oxygen-carrier particles; the wavelength of visible light is 550nm , the radiation intensity is 0.8w / cm 2 ; Class I coalbed methane has not under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Radiation intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com