Advanced control method for thermal power unit boiler turbine coordination system

A control method and technology for thermal power units, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as slow pressure, oscillation, furnace negative pressure and oxygen fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

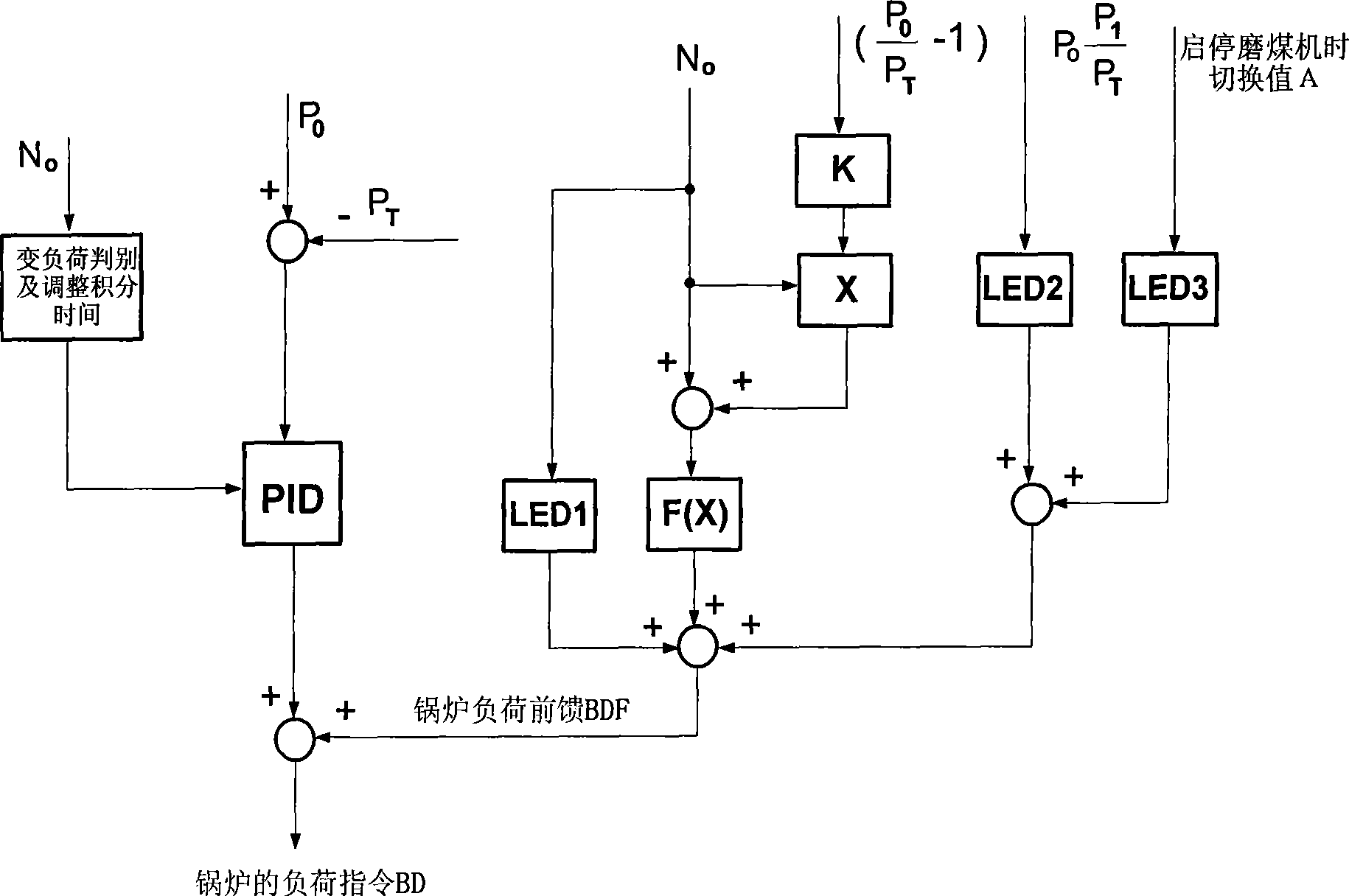

[0038] The advanced control method of the thermal power unit boiler and steam turbine coordination system in this embodiment applies the advanced dynamic feed-forward technology to the feed-forward design of the main control system of the boiler, effectively speeding up the adjustment speed of the boiler load command during the unit load change process . During the variable load process of the unit, the oscillation tendency of the main control system of the boiler is suppressed by reducing the integral action of the regulator. The control method of the boiler load command proposed in this embodiment is as attached figure 1 shown.

[0039] The feed-forward signal of the boiler load command is divided into static feed-forward BDFF s and Dynamic Feedforward BDFF d ,in,

[0040] BDFF s = f { N 0 + k ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com