Water-cooled heat management system of electric automobile battery pack

A thermal management system and electric vehicle technology, applied in the field of electric vehicle battery thermal management, can solve problems such as uneven temperature distribution, over-discharge, and high temperature of the battery pack system, so as to reduce temperature, reduce variance, and eliminate overcharge and overdischarge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

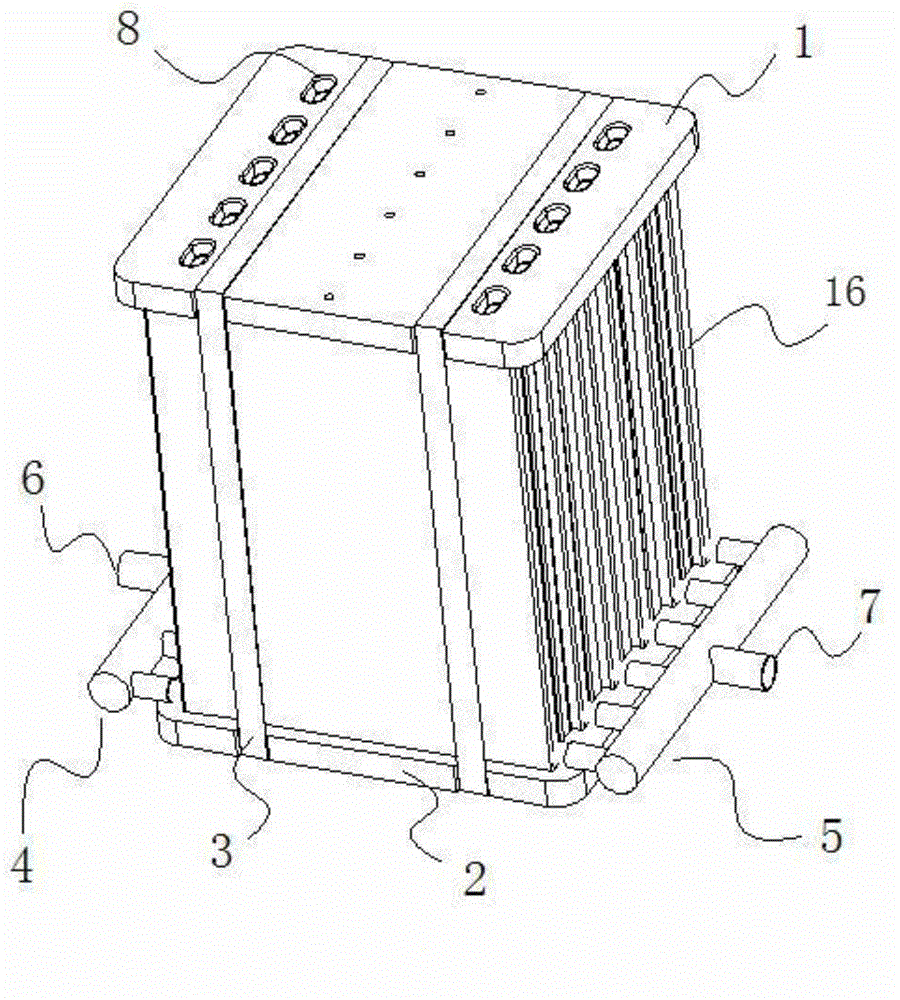

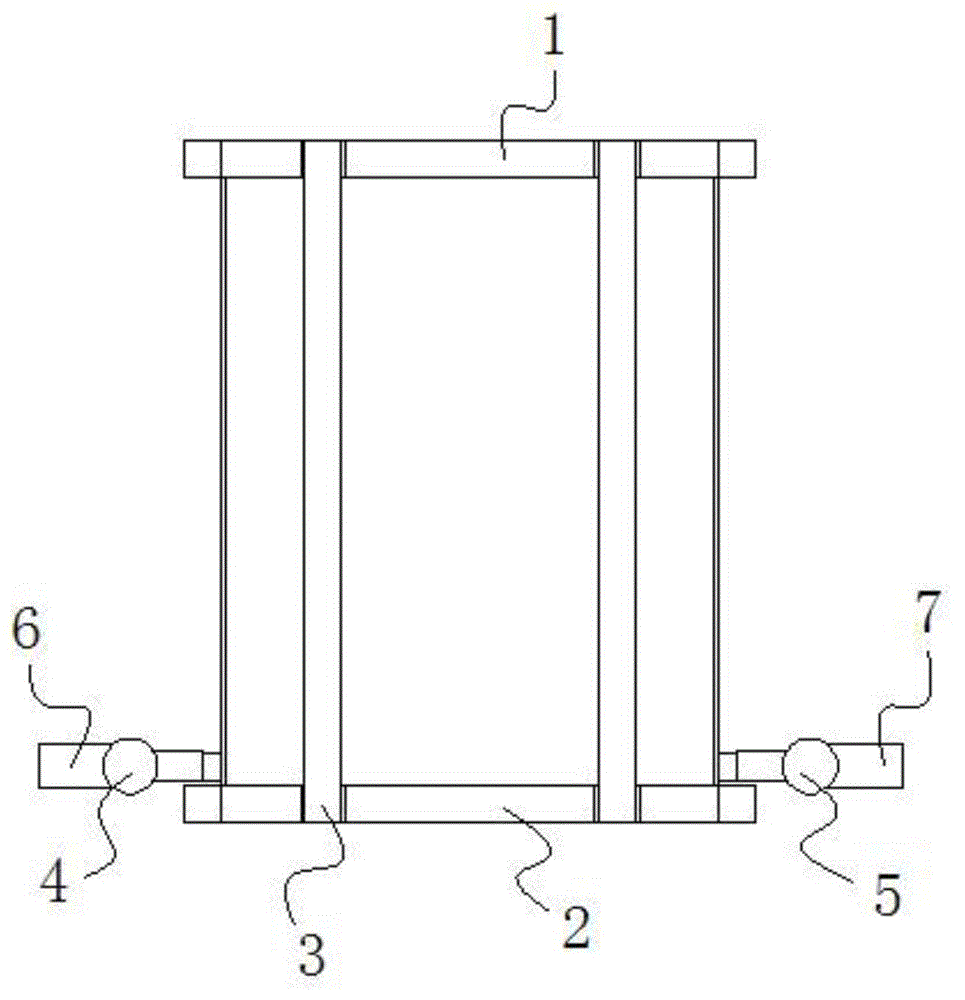

[0037] A water-cooled thermal management system for an electric vehicle battery pack, including an upper fixed baffle 1 and a lower fixed baffle 2, and also includes a power battery 16, a cooling partition 9, a BMS 12, a water pump 13, a heat exchanger 14 and a quick heat connector 15,

[0038] The power battery 16 is fixed between the upper fixed baffle 1 and the lower fixed baffle 2, and the cooling partition 9 is arranged close to the power battery.

[0039] A cooling passage 903 is provided in the cooling partition 9, and the cooling passage 903 includes an input end 901 of a heat transfer working medium and an output end 902 of a heat transfer working medium, and the input end 901 of the heat transfer working medium communicates with the liquid inlet pipe 4, and the heat transfer The output end 902 of the working fluid communicates with the liquid outlet pipe 5 .

[0040]The liquid inlet pipe 4 is connected to the water pump 13 through the liquid inlet connector 6, and t...

Embodiment 2

[0047] The material of the cooling partition 9 is aluminum alloy, which is processed by sheet metal technology. The inside of the cooling partition 9 is a cavity. There is a cooling channel 903 inside the cavity. The advantage of the aluminum alloy material is that it is light in weight and good in thermal conductivity, which helps for the conduction of battery heat. At the two ends of the power battery 16, the power battery 16 and the cooling partition 9 are firmly clamped in the upper and lower two baffles by the upper fixing baffle 1 and the lower fixing 2 . The upper fixed baffle 1 and the lower fixed baffle 2 are made of PA6, which has good wear resistance and toughness. The fixed power battery 16 and the cooling partition fixing groove 11 are processed on the whole piece of raw material. There is a fixing strap 3 on the outermost side to fix the entire power battery 16 .

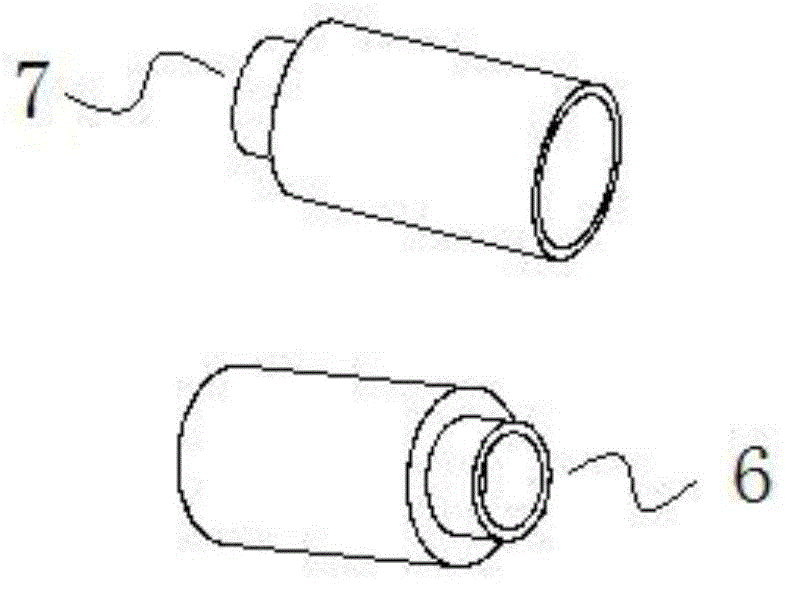

[0048] The liquid inlet connector 6 and the liquid outlet connector 7 are used to connect the cool...

Embodiment 3

[0054] The power battery includes 10 single cells, 6 cooling partitions, the size of the single cell is 343mm×254mm×18.5mm, and the capacity of the single cell is 100AH. The size of the cooling partition 9 is 360mm×270mm×15mm, and it is made of aluminum alloy with a thickness of 1.5mm.

[0055] Such as Figure 10 As shown, the curve where the inverted triangle black point is located is the performance curve when the cross-sectional area of the cooling channel 903 gradually increases, and the cross-sectional area at the input end 901 of the heat transfer working medium is 240mm 2 , the cross-sectional area of the middle section is 540mm 2 , the cross-sectional area at the output end 902 of the heat transfer working medium is 720mm 2 ,

[0056] The curve where the square black dot is located is the performance curve when the interior of the cooling partition 9 is a cavity without flow channels, and the entire cavity is filled with cooling liquid; Area is 75mm 2 (In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com