Capping three-dimensional fabric, and its knitting method

A three-dimensional fabric and fabric technology, applied in the directions of fabrics, knitted fabrics, textiles and papermaking, can solve the problems of poor integrity, poor controllability of lay-up operations, and difficult to guarantee quality, and achieve uniform fiber volume content, convenient practical application, The effect of high damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

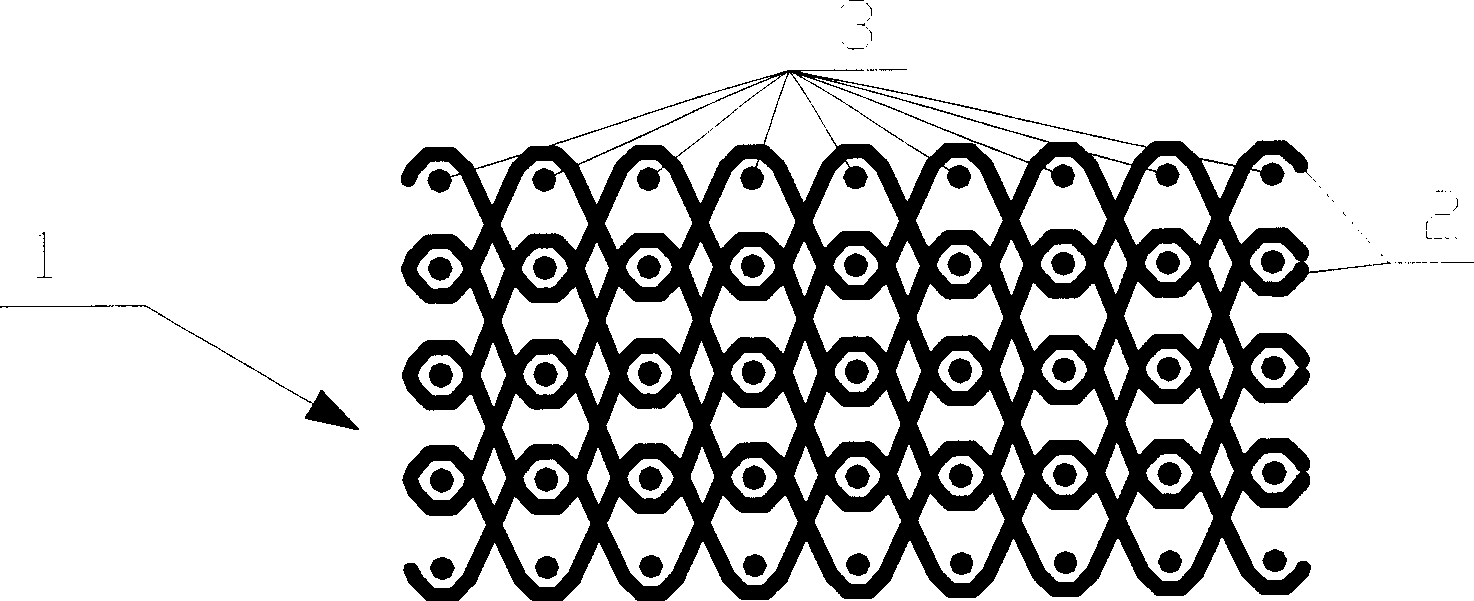

[0036] Adopt the weaving method of the present invention to weave rectangular body capped three-dimensional fabric (referring to Figure 7 ).

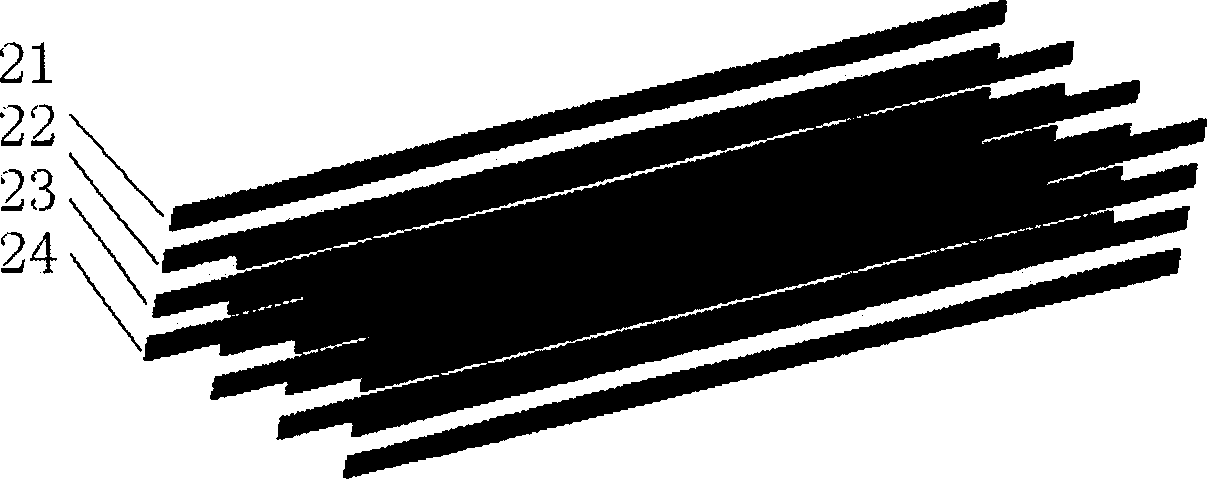

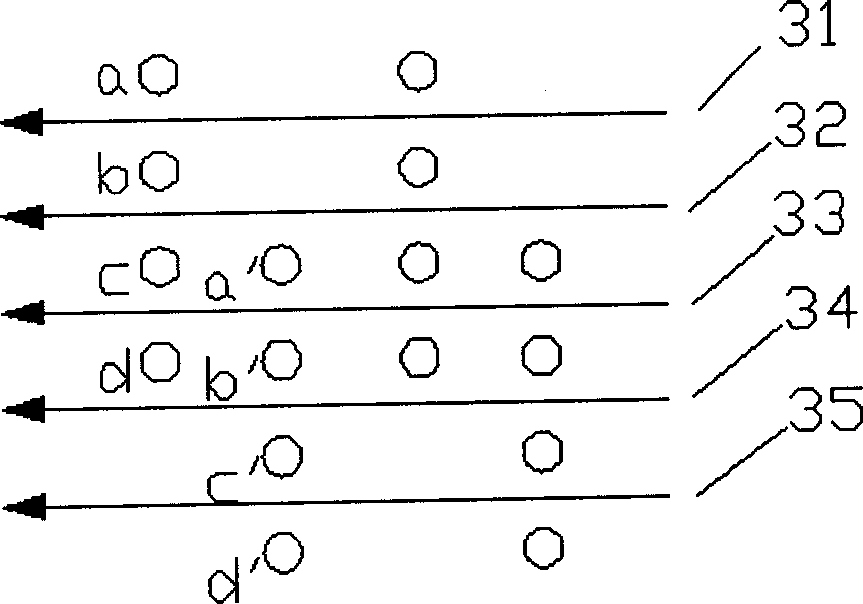

[0037] The top 6 of the rectangular body capping the three-dimensional fabric is rectangular, and the section of the body 7 is also rectangular. Weave the top 6 of the fabric first. The weaving of the top 6 starts from the preset reserved length warp yarn 2, and the warp density is 80 / layer / 10cm, the width of the top 6 is W=100mm, the length of the top 6 is L=120mm, the length of the body 7 is L'=180mm, and the fabric layer Number N=4 layers, the number of rows of the required warp yarn 2 is calculated to be 4, the number of columns is 80, the total number of warp yarns is 320, the length of the required warp yarn 2 is 180×2+120=480mm, and the length of the required weft yarn 3 For 180 * 2+100=460mm, 320 warp yarns 2 are divided into 4 rows, 80 columns, arranged in parallel and straight (see figure 2 ), then hang the two ends of ea...

Embodiment 2

[0039] Adopt the weaving method of the present invention to weave cone capping three-dimensional fabric (referring to Figure 8 , 10 ).

[0040] Theoretically, there is no top 6 and body 7 in the cone-capped three-dimensional fabric, but the cone tip (top local area) with a smaller area, for example, 5mm 2 A small square area is viewed as a cone capping the top of the 3D fabric 6 . Weave the fabric top 6 first. The weaving of the top of the fabric also starts from the preset reserved length warp yarn 2, and the density of the warp yarn 2 is 120 / layer / 10cm, the width of the top 6 is W=5mm, the length of the top 6 is L=5mm, and the length of the body 7 is L'=250mm. The number of layers of the fabric is 12 layers, the calculated number of rows of the required warp yarn 2 is 12, the number of columns is 6, the total number of warp yarns is 72, the length of the required warp yarn 2 is 250×2+5=505mm, and the required weft yarn 3 The length is 250×2+5=505mm, and 72 warp yarns 2 ...

Embodiment 3

[0042] Adopt the weaving method of the present invention to weave trapezoid body capped three-dimensional fabric (referring to Figure 9 ).

[0043] The weaving method of the top 6 of the trapezoid capped three-dimensional trapezoidal fabric is the same as the top weaving method of embodiment 1; the weaving method of its body 7 is the same as the body weaving method of embodiment 2. The specific parameters are designed according to the requirements of the fabric, and can be the same as or different from Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com