Multifunctional tamping machine

A tamping machine and multi-functional technology, applied in construction, infrastructure engineering, soil protection, etc., can solve the problems of reduced construction efficiency, increased cost, and inability to meet inclined surface compaction, achieving good results, high efficiency, compaction, etc. a real effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

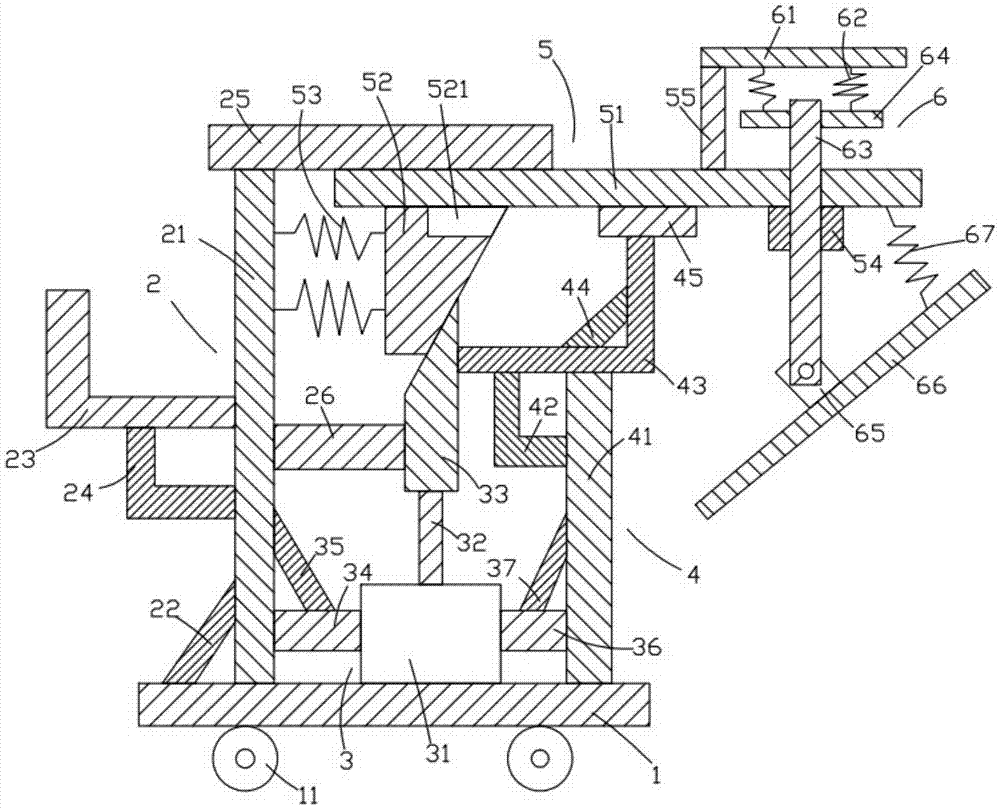

[0018] Such as figure 1 As shown, the multifunctional tamping machine of the present invention includes a base plate 1, a first support device 2 positioned above the base plate 1, a cylinder device 3 located on the right side of the first support device 2, and a cylinder device located on the right side of the cylinder device 3. The second support device 4 , the moving device 5 located above the second support device 4 and the compacting device 6 arranged on the moving device 5 .

[0019] Such as figure 1 As shown, the bottom plate 1 is a cuboid, and the bottom plate 1 is placed horizontally. The bottom plate 1 is provided with a roller 11 located below. The roller 11 is a cylinder, and the roller 11 is placed horizontally. The roller 11 can be Drive the bottom plate 1 to move left and right.

[0020] Such as figure 1 As shown, the first support device 2 includes a first support rod 21, a first oblique rod 22 located on the left side of the first support rod 21, a holding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com