Method for preparing stalk charcoal and stalk vinegar liquid form stalks of cropper

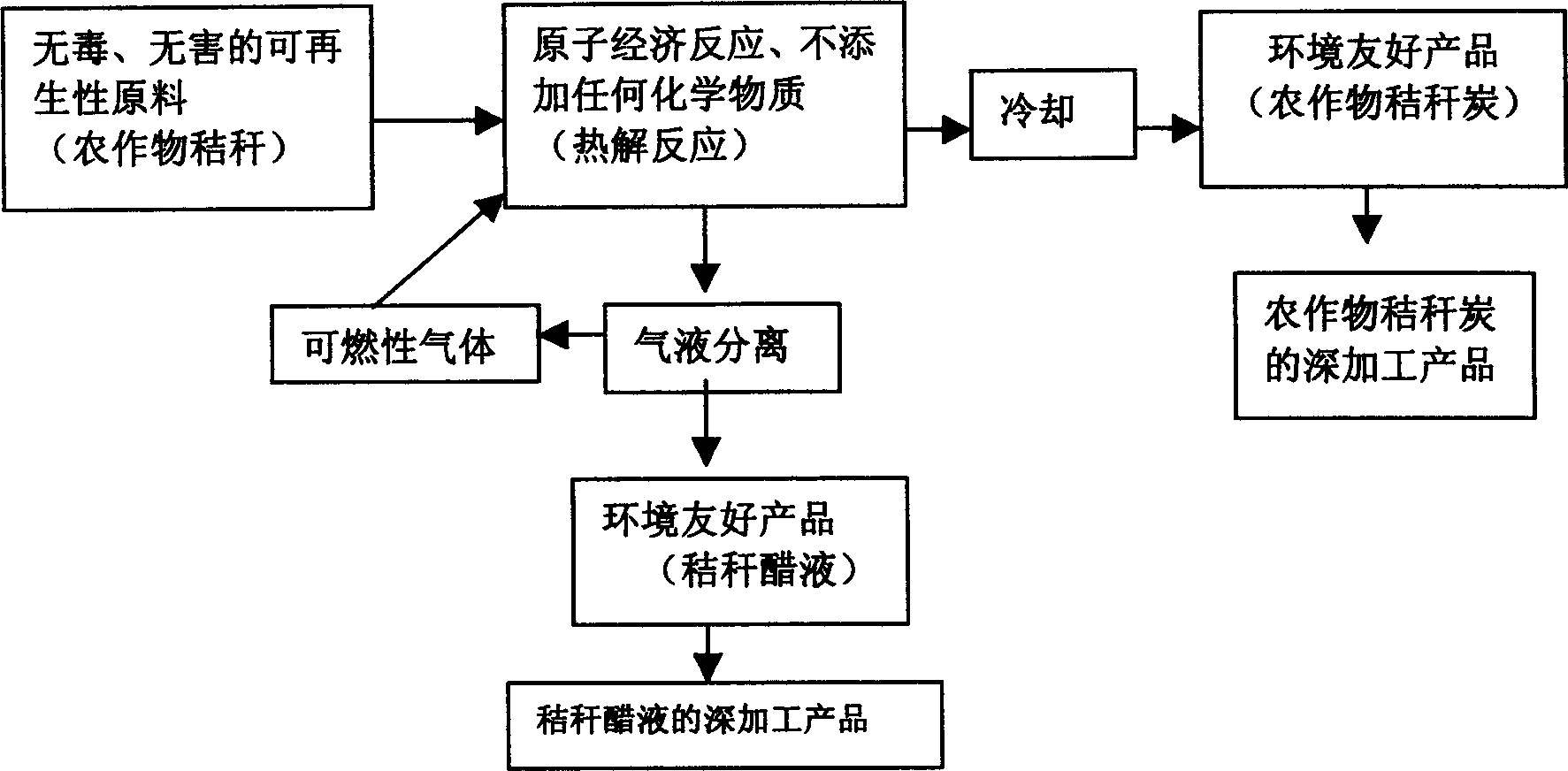

A technology for crop straw and straw charcoal, which is applied in the manufacture of biofuels, pyrolignoic acid, special forms of dry distillation, etc., can solve the problems of environmental pollution, low utilization rate of straw, and poor economic benefits, and achieves increasing soil fertilizer efficiency and improving soil. The effect of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Put the raw material of rice straw into the retort, use the pyrolysis process with the final carbonization temperature of 300°C and 4.5 hours to produce rice straw charcoal and grass vinegar liquid, the solid is cooled to obtain straw charcoal, and the pyrolysis gas is separated into gas and liquid to obtain straw Vinegar liquid and combustible gas, the combustible gas obtained by gas-liquid separation is returned to the combustion chamber to provide heat source for pyrolysis reaction.

[0013] The yield of straw charcoal is 48.23%, and the yield of grass vinegar is 33.46%.

[0014] The chemical composition of rice straw charcoal prepared by pyrolysis process at 300°C for 4.5 hours:

[0015] Ash 36.23%

[0016] Volatile matter 23.45%

[0017] Fixed Carbon 40.32%

Embodiment 2

[0019] Put the raw material of rice straw into the retort, use the pyrolysis process with the final carbonization temperature of 500°C and 5 hours to prepare rice straw charcoal and grass vinegar liquid, and the solid is cooled in the retort to obtain straw charcoal; the pyrolysis gas is separated by gas and liquid Grass vinegar liquid and combustible gas are obtained, and the combustible gas obtained by gas-liquid separation is returned to the combustion chamber to provide heat source for pyrolysis reaction.

[0020] The yield of straw charcoal was 38.00%, and the yield of grass vinegar was 36.00%. Elemental composition of straw charcoal:

[0021] K 3.10%

[0022] Na 2718.02mg / kg

[0023] Ca 1.30%

[0024] N 8180mg / kg

[0025] Mg 2866.28mg / kg

[0026] Zn 39.18mg / kg

[0027] Fe 818.42mg / kg

[0028] Cu 23.39mg / kg

[0029] P 3957.57mg / kg

[0030] Al 833.41mg / kg

[0031] Ni 16.64mg / kg

[0032] B 60.42mg / kg

[0033] M...

Embodiment 3

[0039] Put the corn stalk raw material into the retort, and use the pyrolysis process with the final carbonization temperature of 500°C and 5 hours to produce corn stalk charcoal and corn stalk vinegar liquid. The solid is cooled to obtain corn stalk charcoal, and the pyrolysis gas is passed through gas-liquid Corn stalk vinegar liquid and combustible gas are obtained through separation, and the combustible gas obtained through gas-liquid separation is sent back to the combustion chamber to provide heat source for pyrolysis reaction.

[0040] The yield of corn stalk charcoal is 30.00%, and the yield of corn stalk vinegar is 37.00%

[0041] Chemical composition of corn stalk charcoal:

[0042] Ash 9.03%

[0043] Volatile 16.16%

[0044] Fixed Carbon 74.81%

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com