Liquefied natural gas carrier B type independent liquid cargo tank thermal insulation system and construction method thereof

A technology for liquefied natural gas and liquid cargo tanks, applied in the direction of bulk cargo, etc., can solve the problems that the thermal insulation system of liquefied natural gas ships is not suitable for installation, and achieve the effect of solving structural design and installation process technical difficulties and reducing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

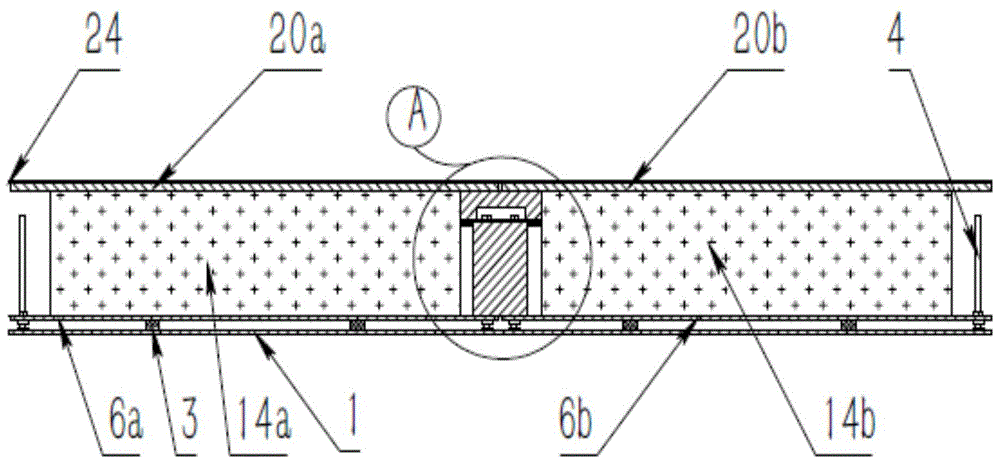

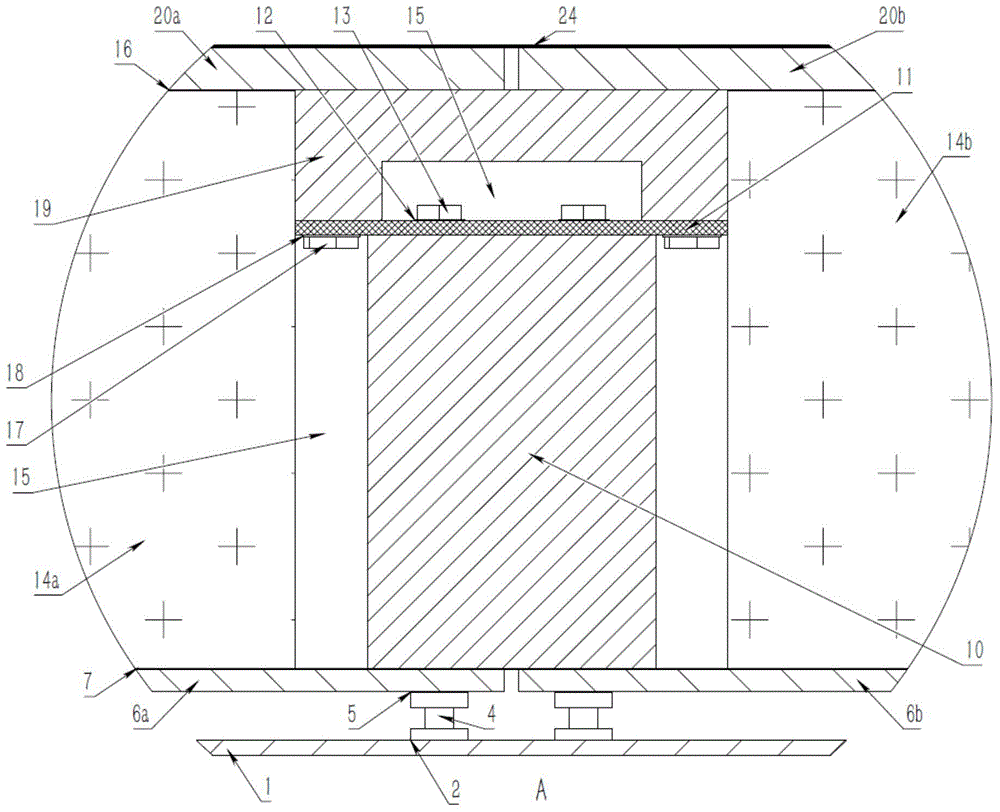

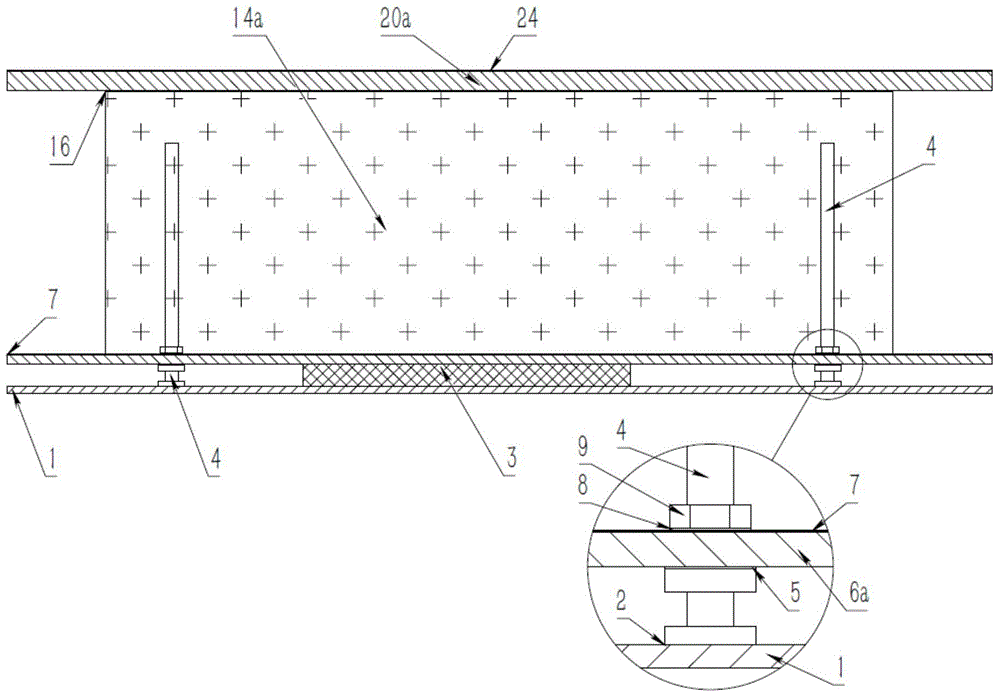

[0068] This embodiment provides a type B independent liquid cargo tank insulation system for LNG ships, which includes a heat insulation layer, and the heat insulation layer includes a splash screen, a secondary barrier layer, a heat insulation board, an upper plate and a protective layer, wherein the The secondary screen wall layer is continuously bonded on the upper surface of the splash screen, the heat insulation board is sandwiched between the splash screen and the upper plate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com