METHOD, SYSTEM, AND PRODUCTION AND STORAGE FACILITY FOR OFFSHORE LPG and LNG PROCESSING OF ASSOCIATED GASES

a technology of applied in passenger handling equipment, lighting and heating equipment, borehole/well accessories, etc., can solve the problems of large and complex vessels, no lng production facilities, and the addition of lpg production, lng production and storage facilities, etc., and achieve the effect of storage, and improving the efficiency of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

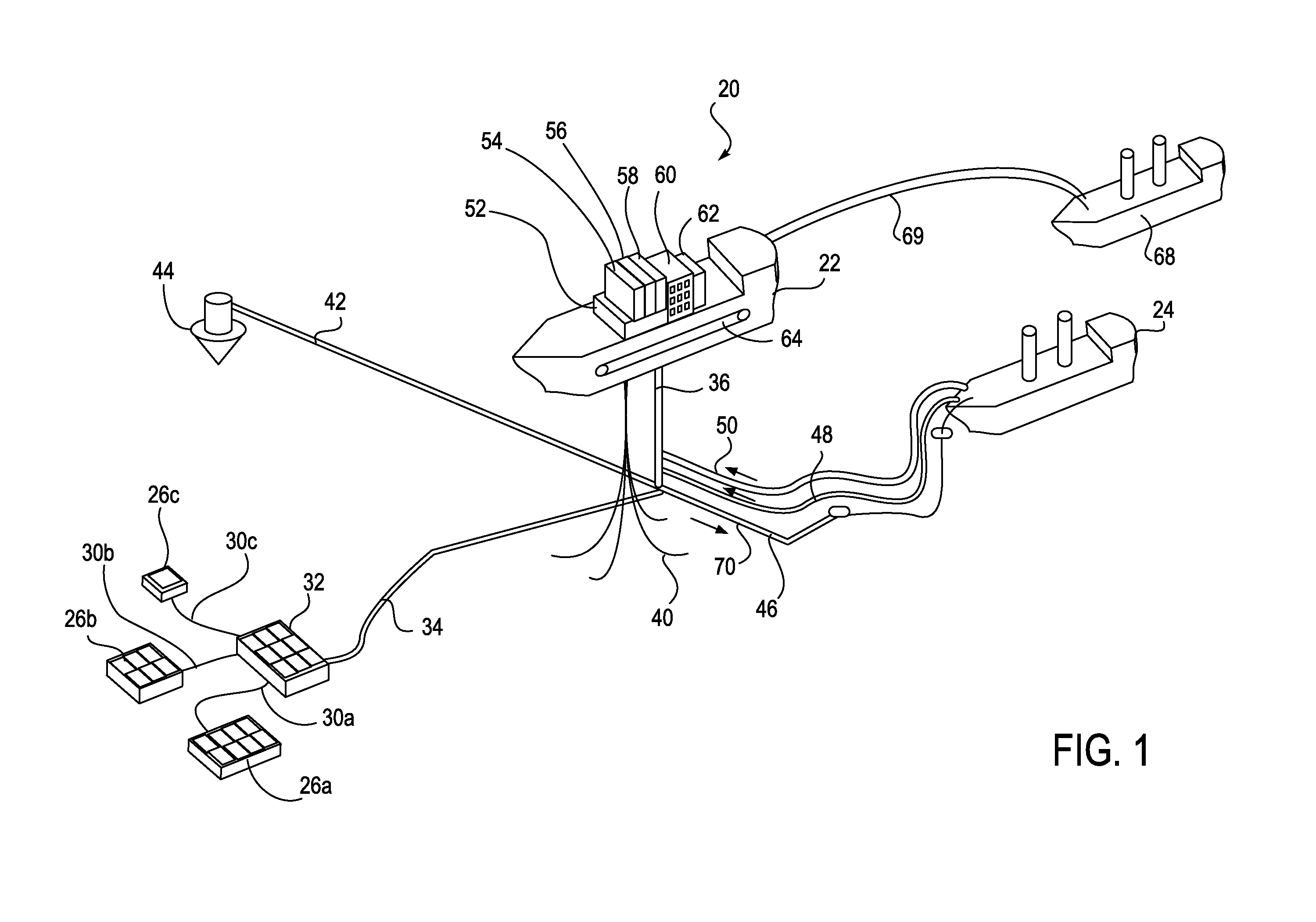

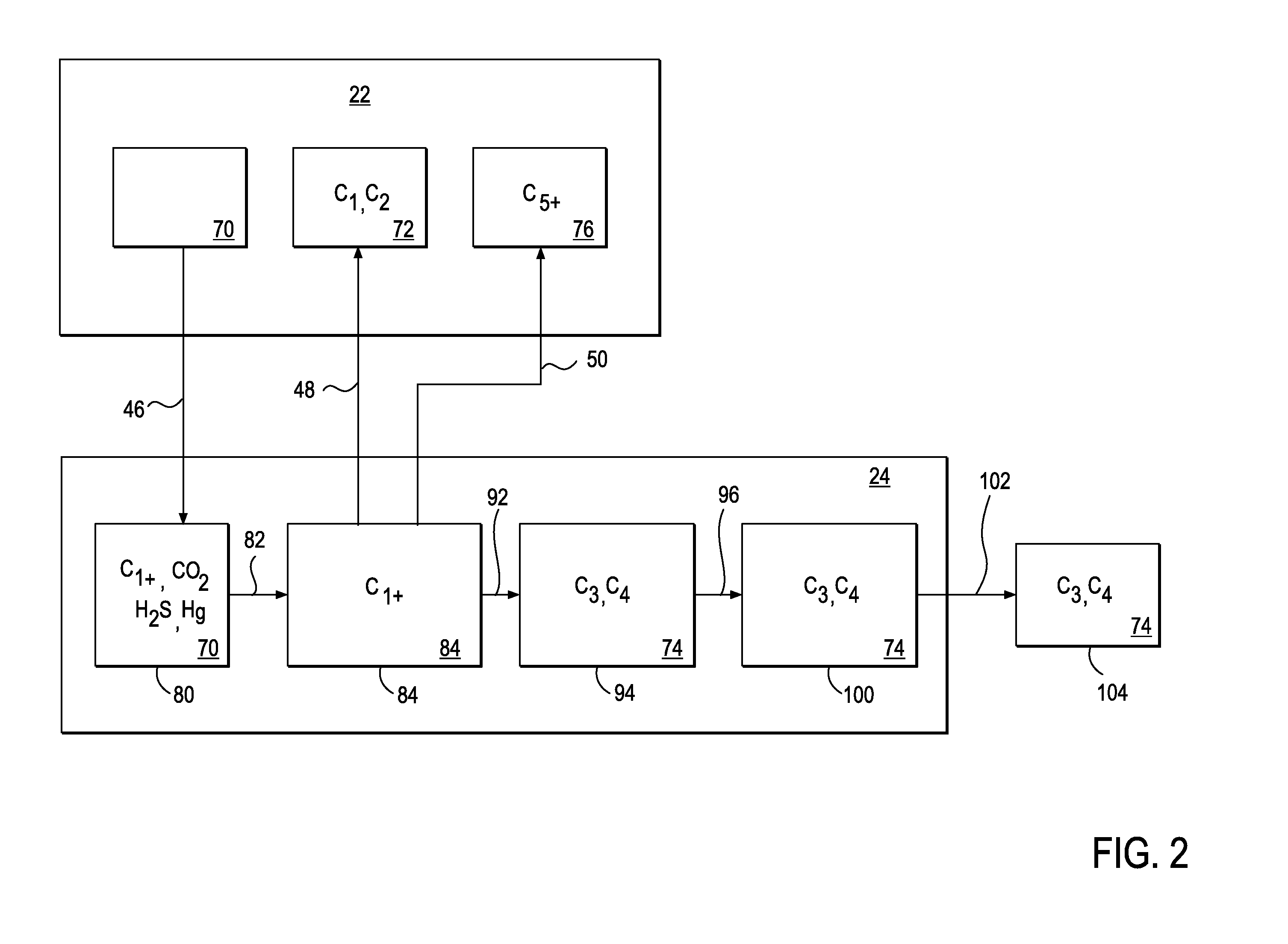

[0020]For the purposes of this disclosure, the following terms shall have following meanings:

[0021]Condensate refers to liquids recovered from rich associated gases having predominantly C5+ hydrocarbons;

[0022]LNG (Liquefied natural gas) refers to a cryogenic fluid comprising predominately methane (C1) with lesser amounts of C2+ hydrocarbons, which is sufficiently cold to remain in a liquid state at or near atmospheric pressures;

[0023]LPG (Liquefied petroleum gas) refers to fluids comprising predominately C3 and C4 hydrocarbons, which can either be refrigerated to remain liquid at near atmospheric pressures or pressurized to remain liquid at atmospheric temperature;

[0024]Residue gas refers to gases recovered from LPG or LNG processing that contain primarily C1 and C2 hydrocarbons;

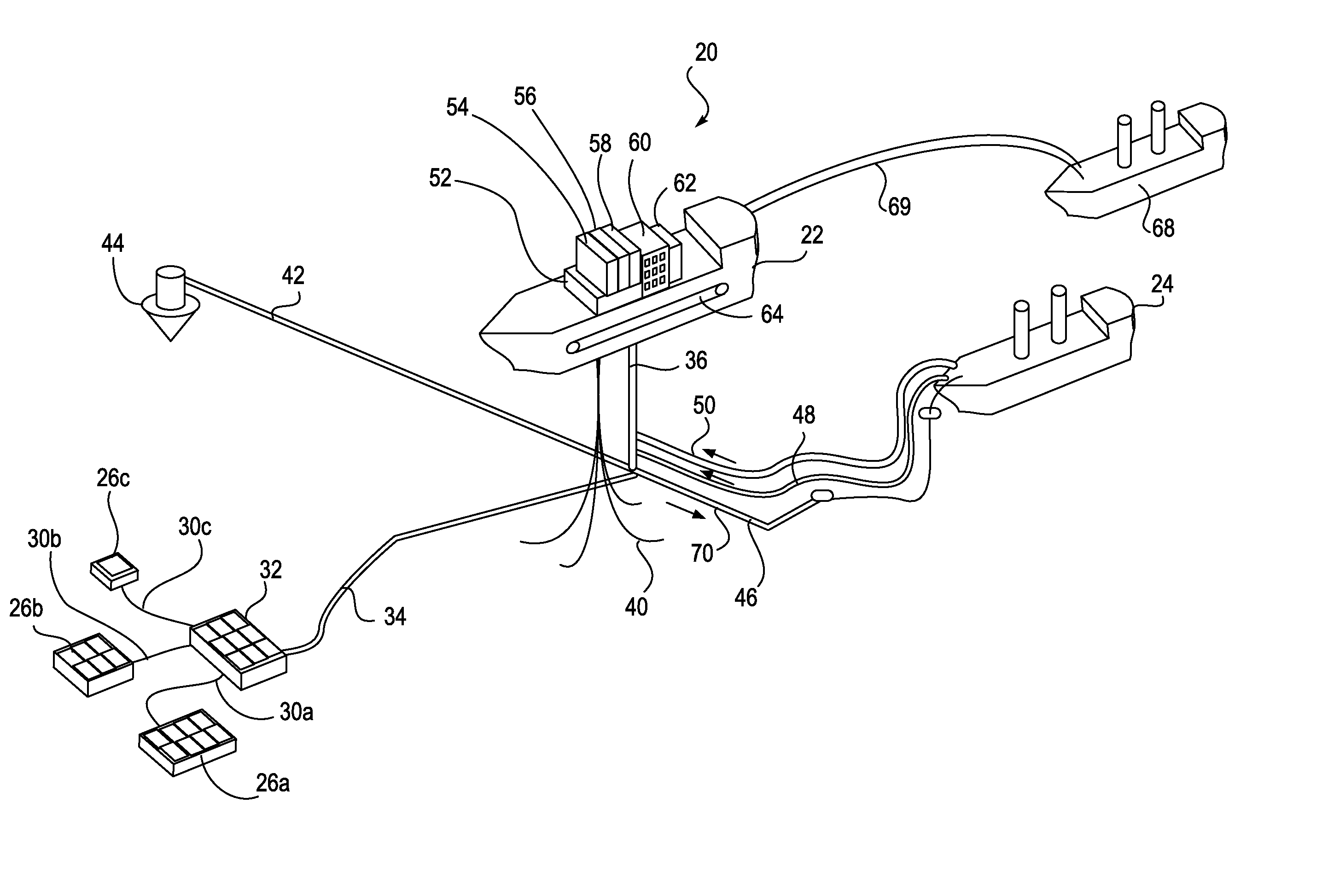

[0025]Rich associated gases refers to gases separated from hydrocarbon containing produced fluids on a first production facility, including crude oil and water, which contain contaminants, such as acid gases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com