Production process of magnesia used for rear earth solution precipitator

A production process and rare earth solution technology, which is applied in the field of rare earth preparation to achieve the effects of reducing production costs, expanding the scope of application and solving wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

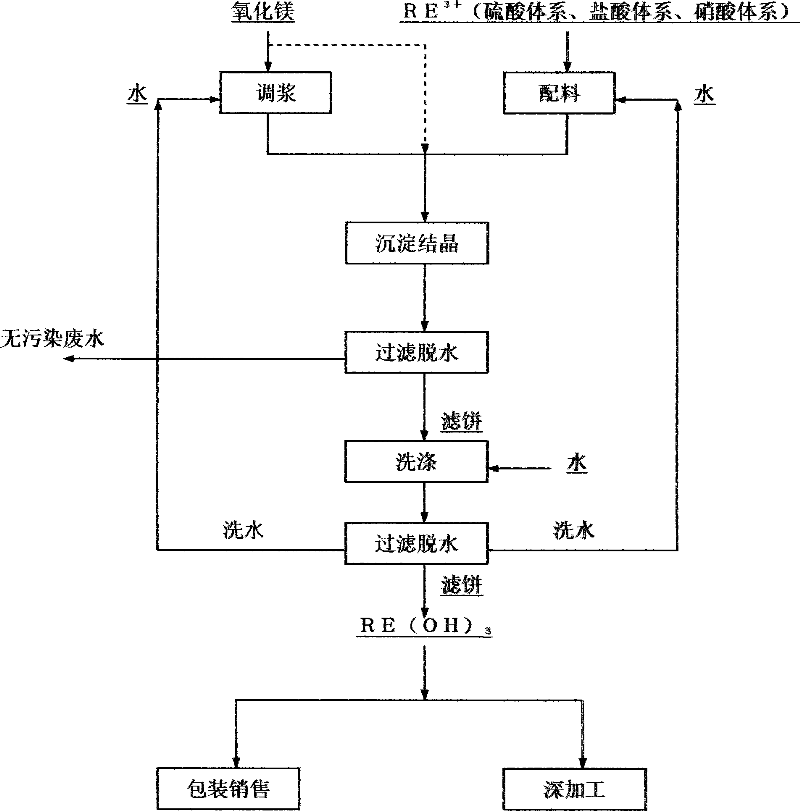

Method used

Image

Examples

Embodiment 1

[0020] (1) Add 2.5m 3 Water, heated to 40±5°C, add 375Kg magnesia, stir and adjust the slurry.

[0021] (2) Add mixed sulfuric acid rare earth material containing La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y in the batching tank with a rare earth concentration of 50g / L Liquid 20m 3 , add water 5m 3 , Stir the ingredients, detect that the rare earth concentration is 40.5g / L, and heat to 40±5°C.

[0022] (3) the magnesium oxide slurry prepared in the step (1) and the rare earth feed liquid prepared in the step 2) were respectively mixed with 2.5m 3 / hour and 25m 3 The flow rate per hour is fed into the precipitation reaction tank, and the feeding is stopped after 1 hour, and the stirring is continued for 90 minutes (controlling the reaction temperature: between 40±5°C). The concentration of rare earth in the supernatant is detected to be 0.08g / L, and the precipitated slurry is poured into the transition tank for filtration and dehydration to produce a filter c...

Embodiment 2

[0031] (1) Add 1.0m 3 Water, heated to 55±5°C, add 375Kg magnesia, stir and adjust the slurry.

[0032] (2) Add mixed sulfuric acid rare earth material containing La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y in the batching tank with a rare earth concentration of 50g / L Liquid 20m 3 , add water 10m 3 , Stir the ingredients, detect that the rare earth concentration is 33.8g / L, and heat to 60±5°C.

[0033] (3) Pour the magnesium oxide slurry prepared in step (1) into the precipitation reaction tank first, and then mix the rare earth feed liquid prepared in step 2) with 30m 3 The flow rate per hour is fed into the precipitation reaction tank, and the feeding is stopped after 60 minutes, and the stirring is continued for 130 minutes (controlling the reaction temperature: between 60±5°C). The rare earth concentration of the supernatant was detected to be 0.02g / L, and the precipitated slurry was poured into the transition tank for filtration and dehydration to produc...

Embodiment 3

[0042] (1) Add 2.5m 3 Water, heated to 75±5°C, add 375Kg magnesia, stir and adjust the slurry.

[0043] (2) Add mixed sulfuric acid rare earth material containing La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y in the batching tank with a rare earth concentration of 50g / L Liquid 20m 3 , add water 10m 3 , Stir the ingredients, detect that the rare earth concentration is 33.1g / L, and heat to 40±5°C.

[0044] (3) Put the rare earth material liquid prepared in step 2) into the precipitation reaction tank first, and then mix the magnesium oxide slurry prepared in step (1) with 2.0m 3 The flow rate per hour is fed into the precipitation reaction tank, and the feeding is stopped after 75 minutes, and the stirring is continued for 110 minutes (controlling the reaction temperature: between 40±5°C). The rare earth concentration of the supernatant was detected to be 0.12g / L, and the precipitated slurry was poured into the transition tank for filtration and dehydration to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com