Mobile vibrating and activating device of large bunker

A silo and large-scale technology, applied in large containers, packaging, transportation and packaging, etc., can solve the problems of overheating and burning of vibration motors, labor occupation, etc., and achieve the effect of low cost, small maintenance and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

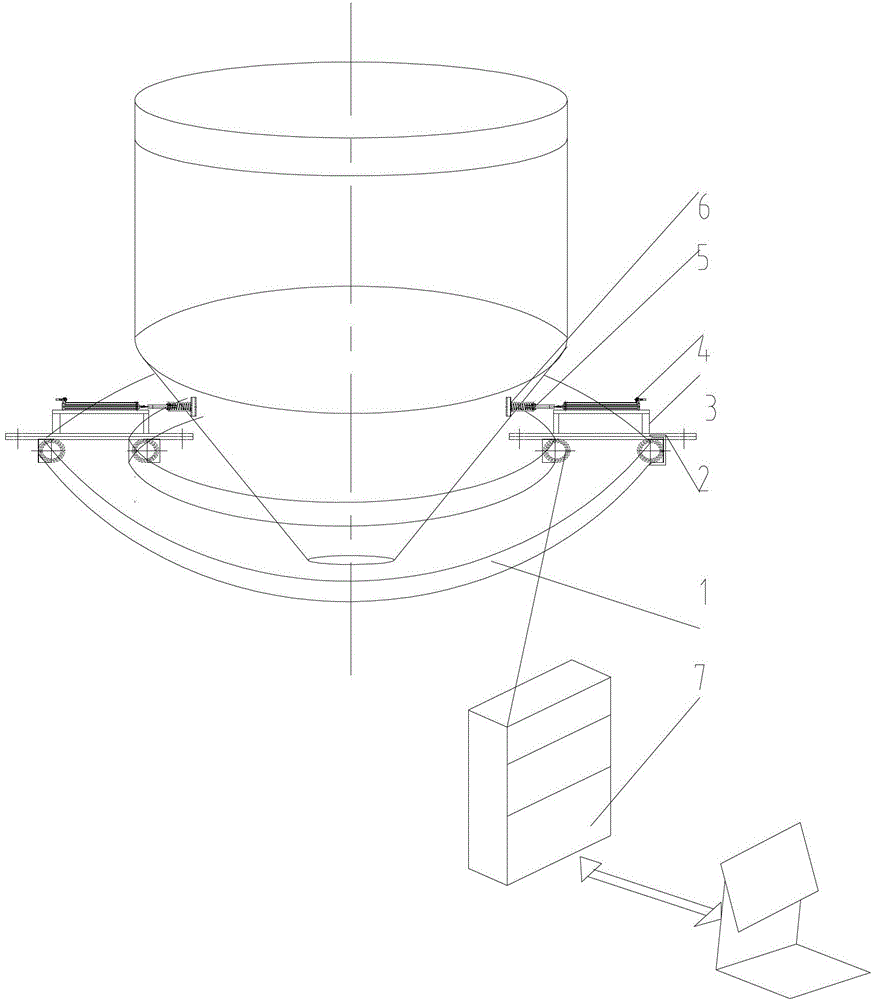

[0011] Embodiment 1 A mobile vibration activation device composition of a large hopper and the effect of each part:

[0012] The invention relates to a mobile vibration activation device for a large-scale silo, in particular to an external mobile vibration activation device for a large-scale silo whose stored materials are affected by process equipment and are prone to high viscosity and unsmooth feeding, a large-scale silo The mobile vibration activation device consists of a circular track 1 for the ring silo, a fixed trolley 2 for the vibration activation device, a rack 3 for the vibration activation device, a cylinder 4, a buffer spring 5, a vibration hitting arc plate 6, and an electrical control system 7. The feature is that each component of the vibration activation device is installed on the fixed trolley 2 of the vibration activation device and moves along the circular rail 1 of the ring silo, relying on the vibration to hit the arc plate 6 to hit the silo wall to act...

Embodiment 2

[0013] Embodiment 2 The working process of a mobile vibration activation device for a large silo:

[0014] By observing the continuous and smooth condition of material discharge, set the frequency and position of the cylinder through the electric control system, so that the vibration hits the arc plate 6 and vibrates against the wall of the warehouse, so that the materials adhered to the wall of the warehouse fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com