Bulk cargo ship liquefied natural gas bunker arrangement structure

A technology of liquefied natural gas and layout structure, which is applied in the field of liquefied natural gas fuel tank layout structure of bulk carriers, can solve the problems of insufficient safety, weak structural strength, difficult layout, etc. The effect of high directional utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

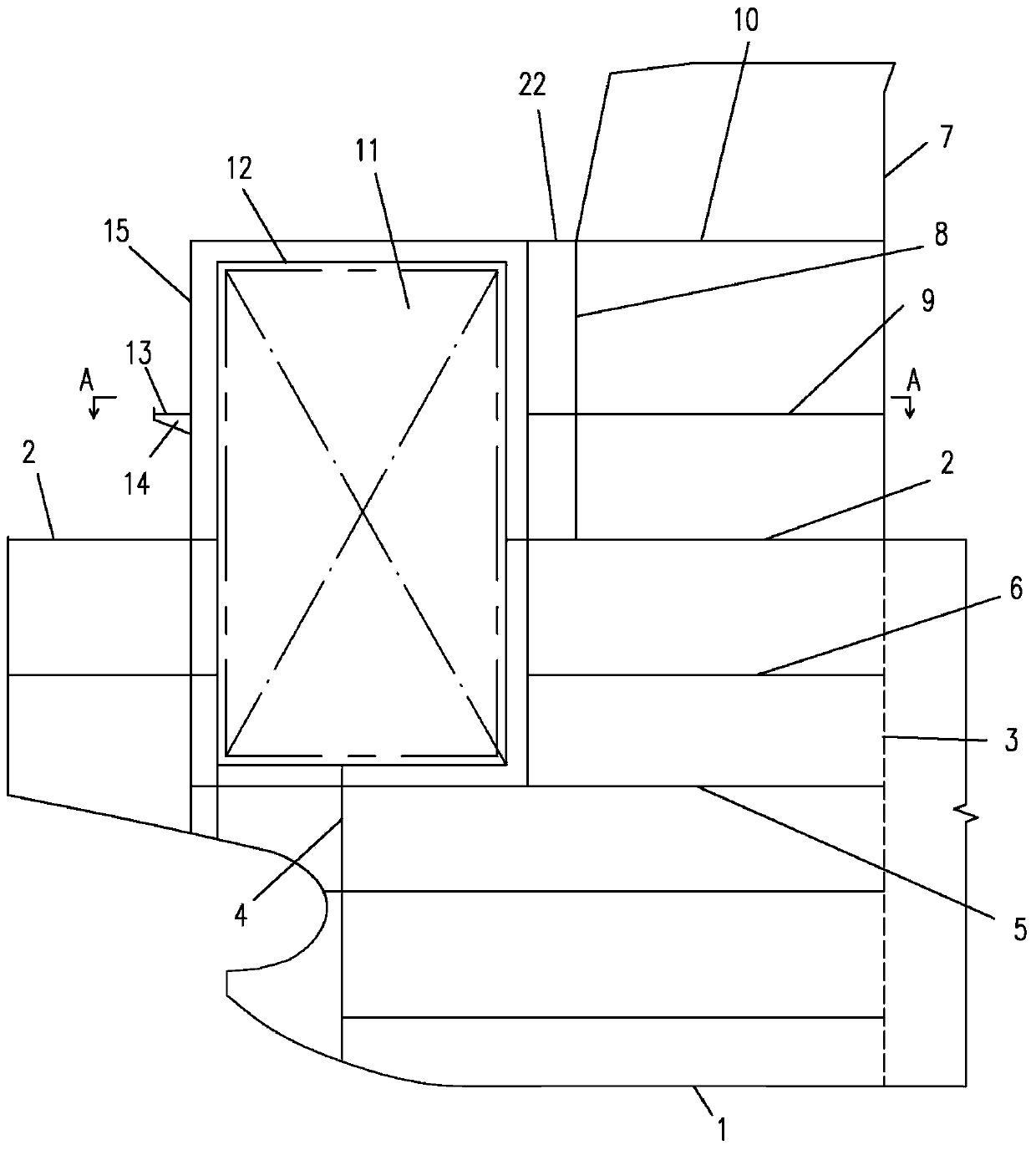

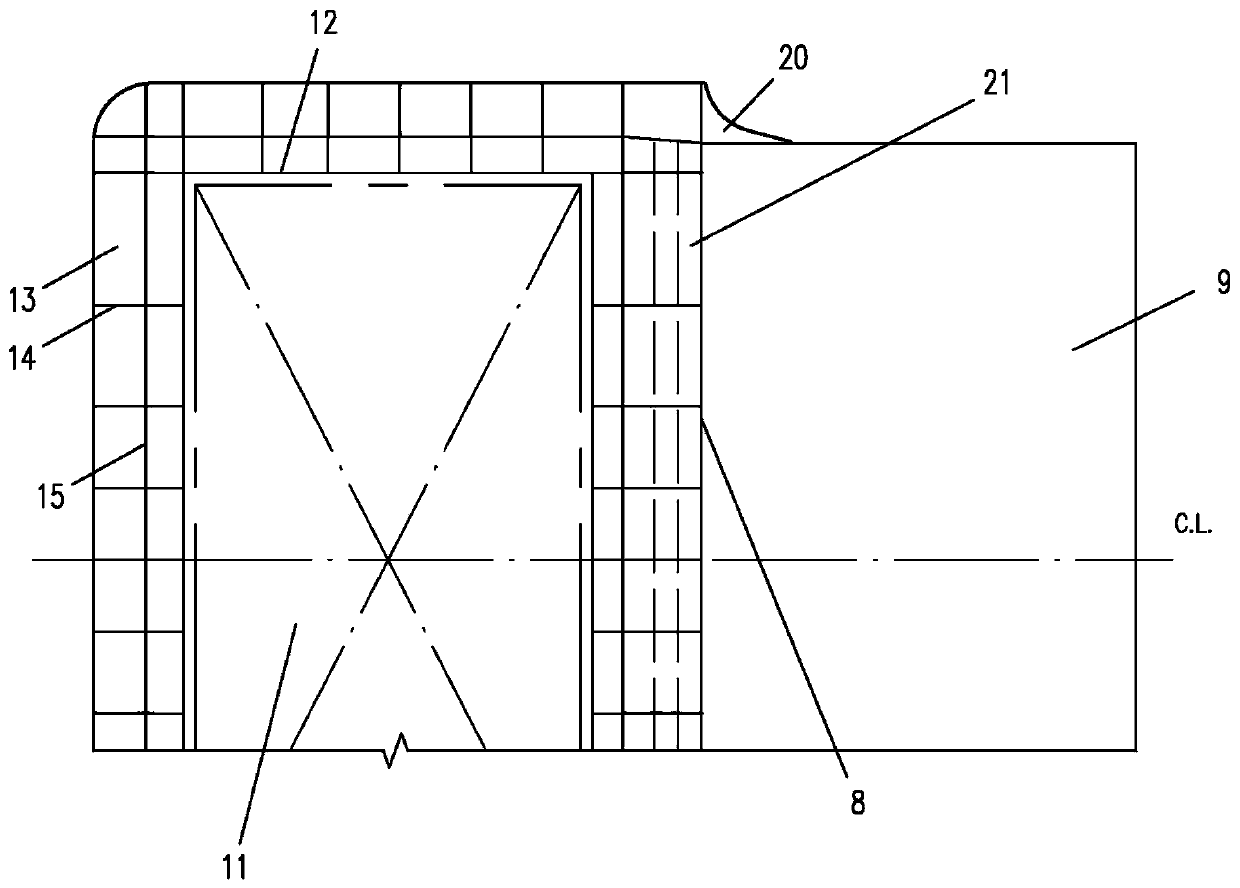

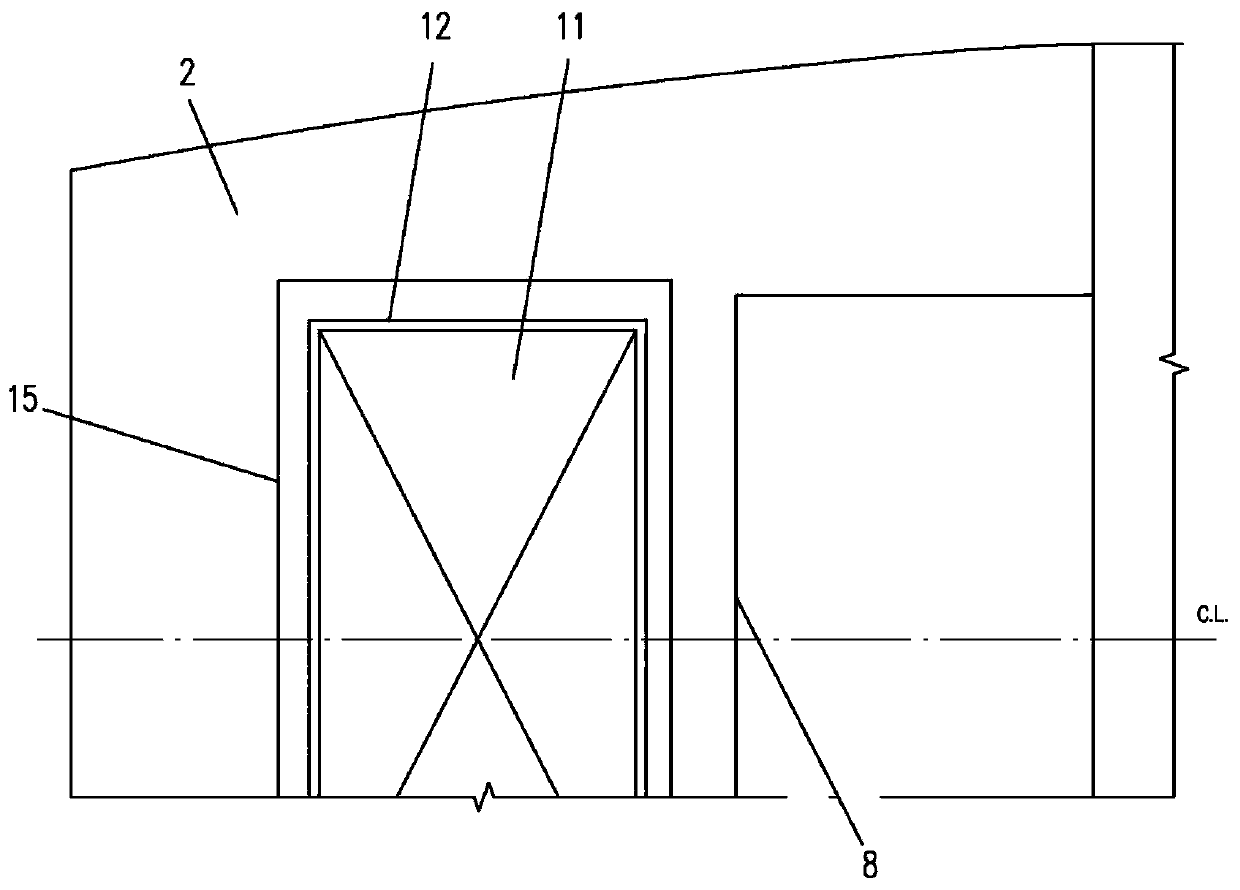

[0025] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a bulk carrier liquefied natural gas fuel tank arrangement structure includes a liquefied natural gas fuel tank 11 .

[0027] Such as figure 1 As shown, the stern of the bulk carrier is mainly composed of hull shell plate 1, upper deck 2, engine room front wall 3, engine room rear end wall 4, engine room lower platform 5, engine room upper platform 6, superstructure front wall 7, superstructure rear The end wall 8, the superstructure B deck 9, the superstructure D deck 10 and other components are composed.

[0028] The liquefied natural gas fuel tank 11 is arranged at the rear of the superstructure, and the liquefied natural gas fuel tank 11 includes an outer shell 15 and an inner shell 12 .

[0029] The liquefied natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com