Patents

Literature

32results about How to "Address structural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

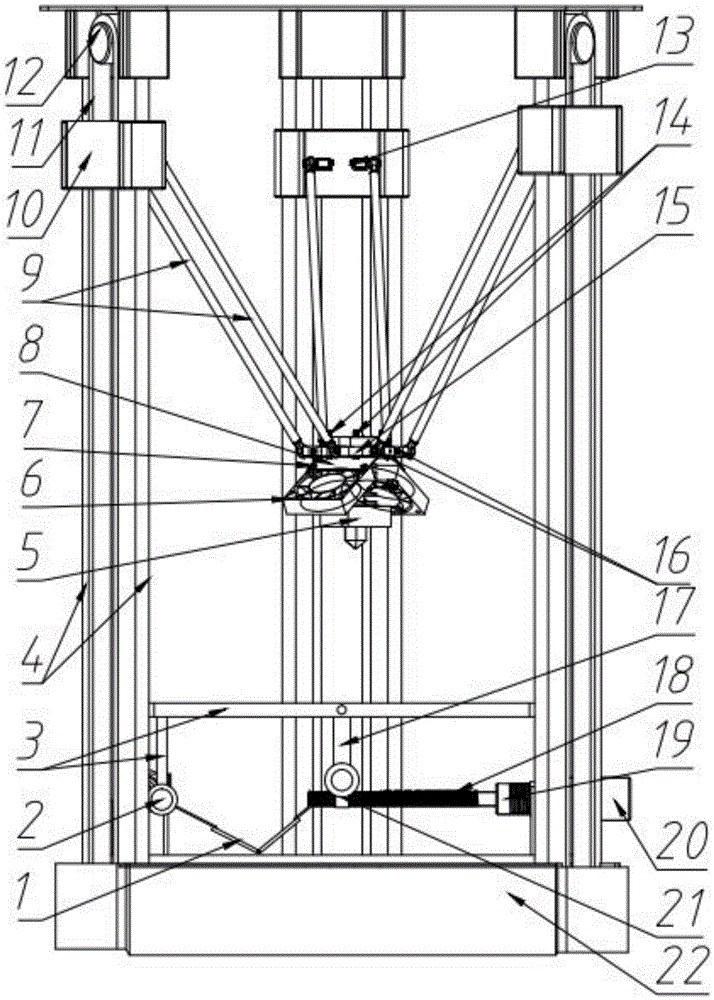

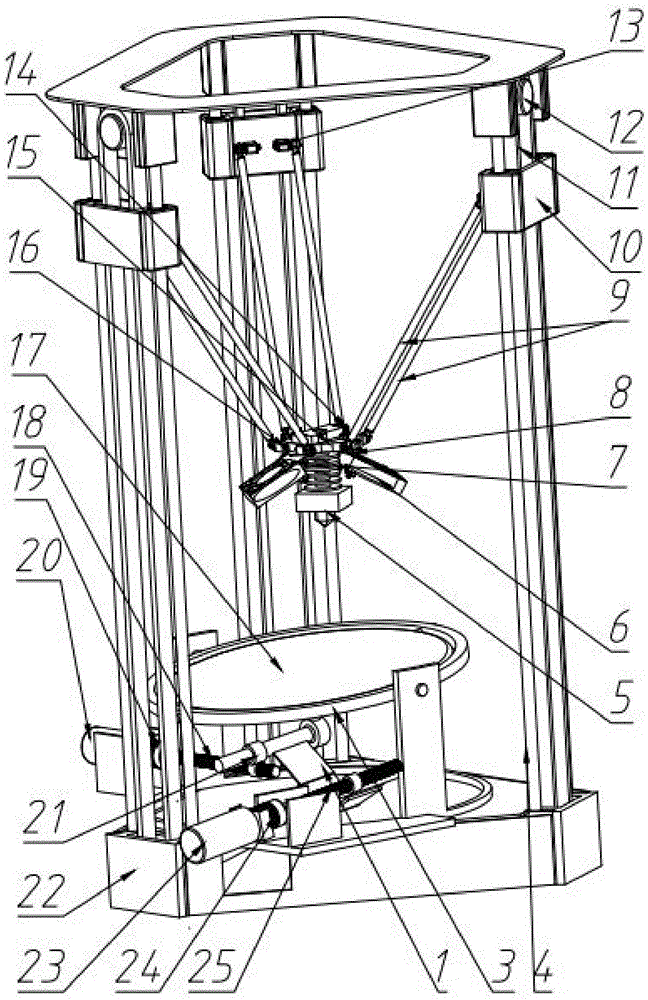

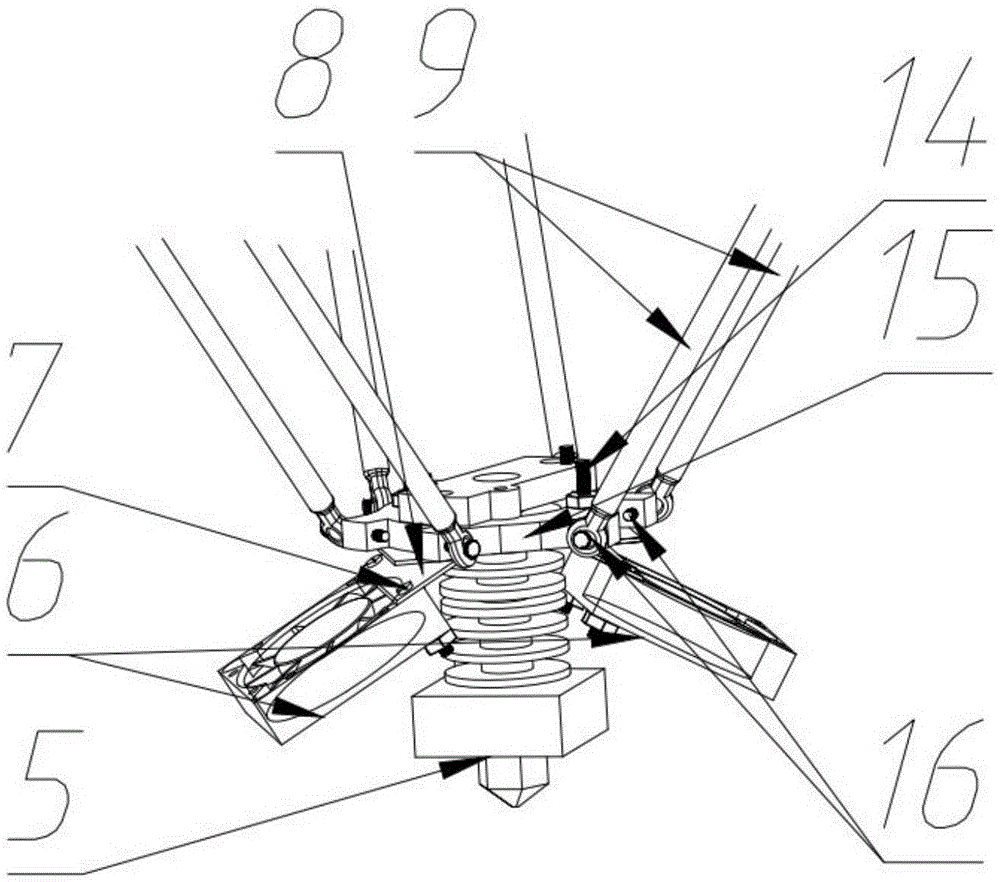

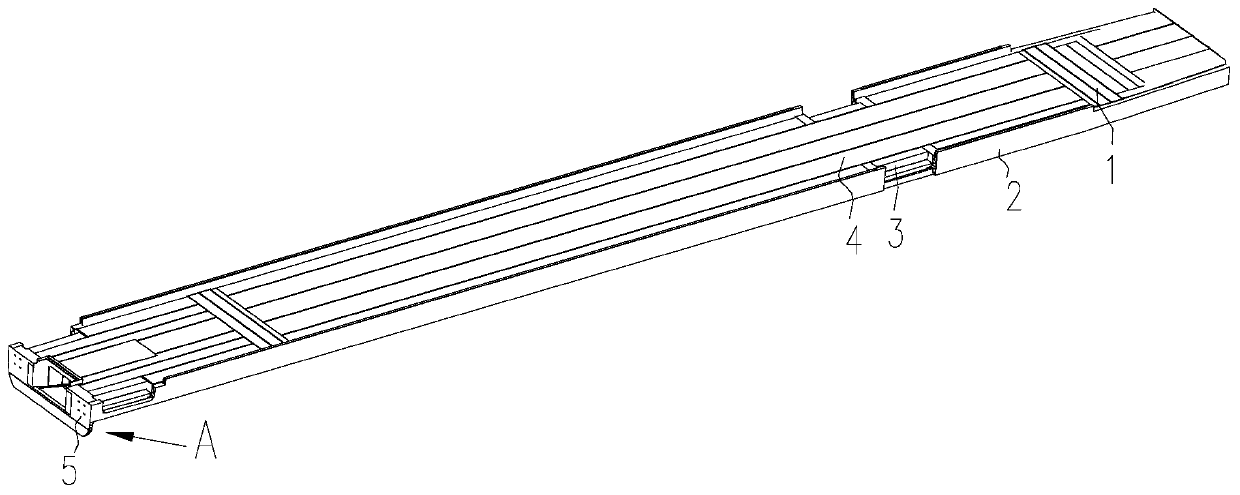

Five-axis linkage 3 D printer mechanism

ActiveCN105599294AImprove stabilityIncrease stiffnessAdditive manufacturing apparatusWaxPlastic materials

The present invention relates to a five-axis linkage 3 D printer mechanism. The five-axis linkage 3 D printer mechanism is characterized in that: two-axis printing of a lower dynamic platform can be achieved by two screw rod drivers, a parallel mechanism is used to achieve three-axis printing of an upper dynamic platform, and the five-axis linkage 3 D printer mechanism mainly comprises a machine body system, a control system, a printing system and a display system. The 3D printer is on the basis of digital model files, the digital model files are sliced, a special wax material, a powdered metal or a plastic material and other adhesive materials is used, x, y and z-axis mobile printing can be achieved by an extrusion head controlled by the parallel mechanism, the two screw rod drivers control the lower dynamic platform to achieve v-axis rotating printing, and then a three-dimensional object is produced by use of the layer-by-layer adhesive materials to achieve five-axis linkage printing of a three-dimensional entity.

Owner:CHANGZHOU UNIV

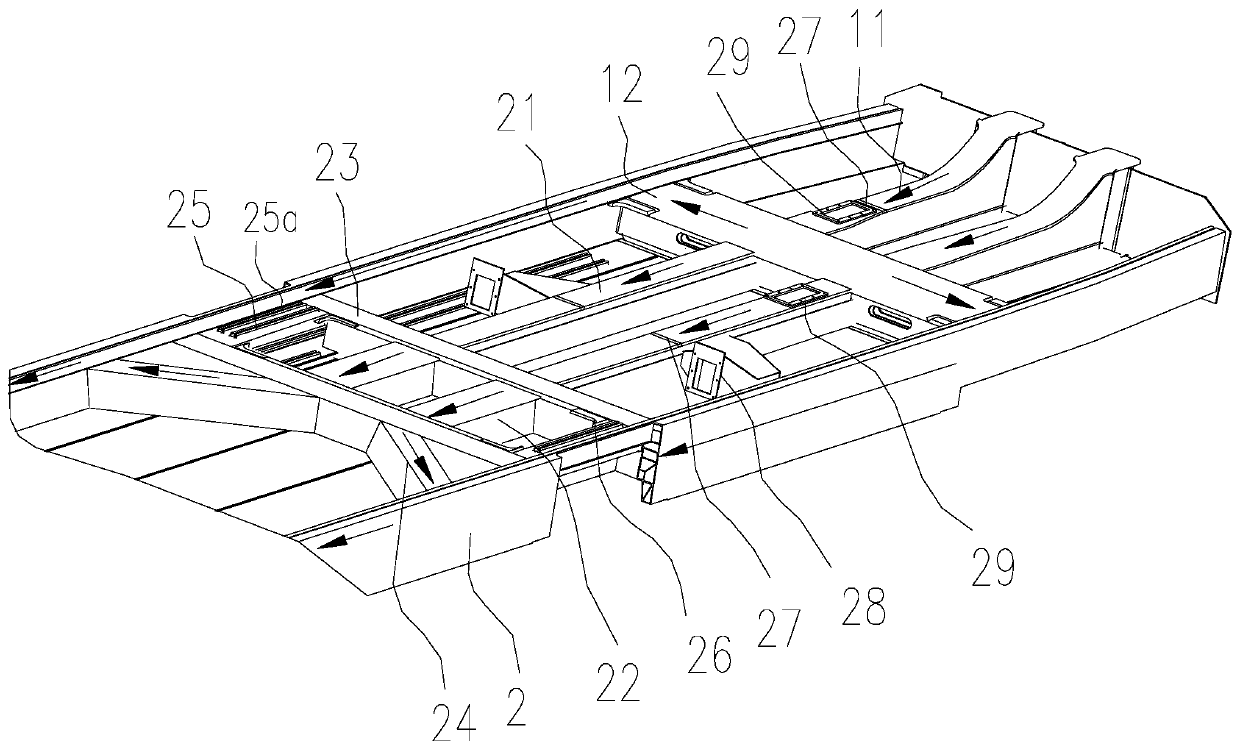

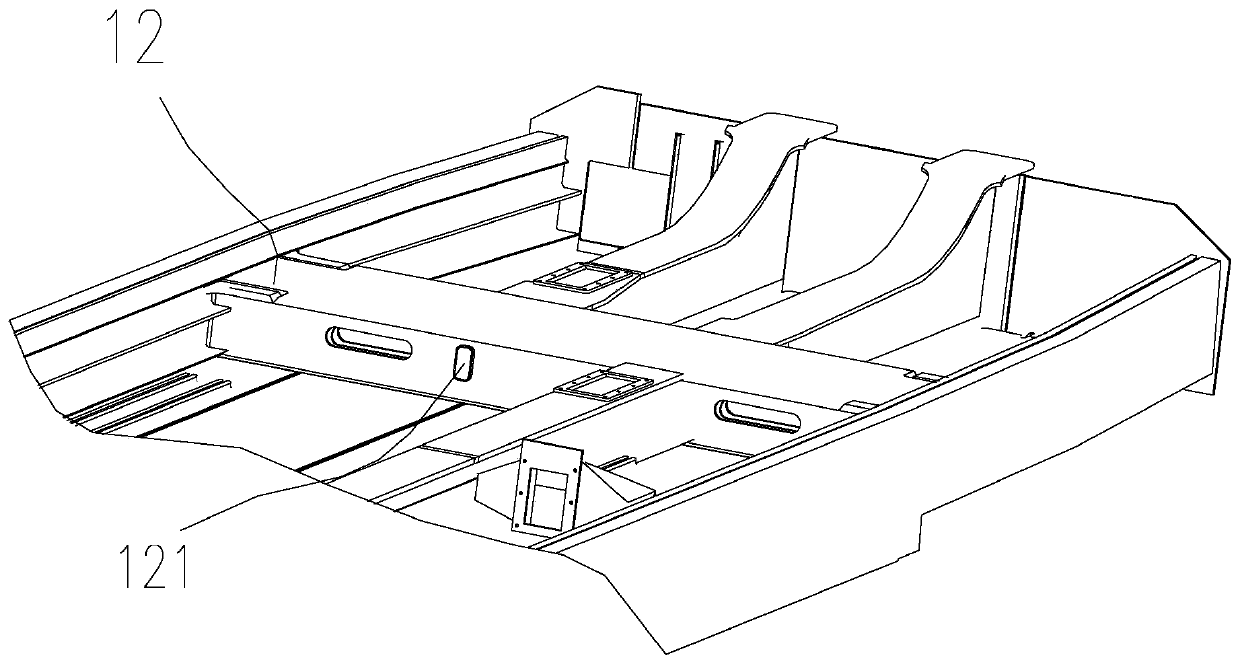

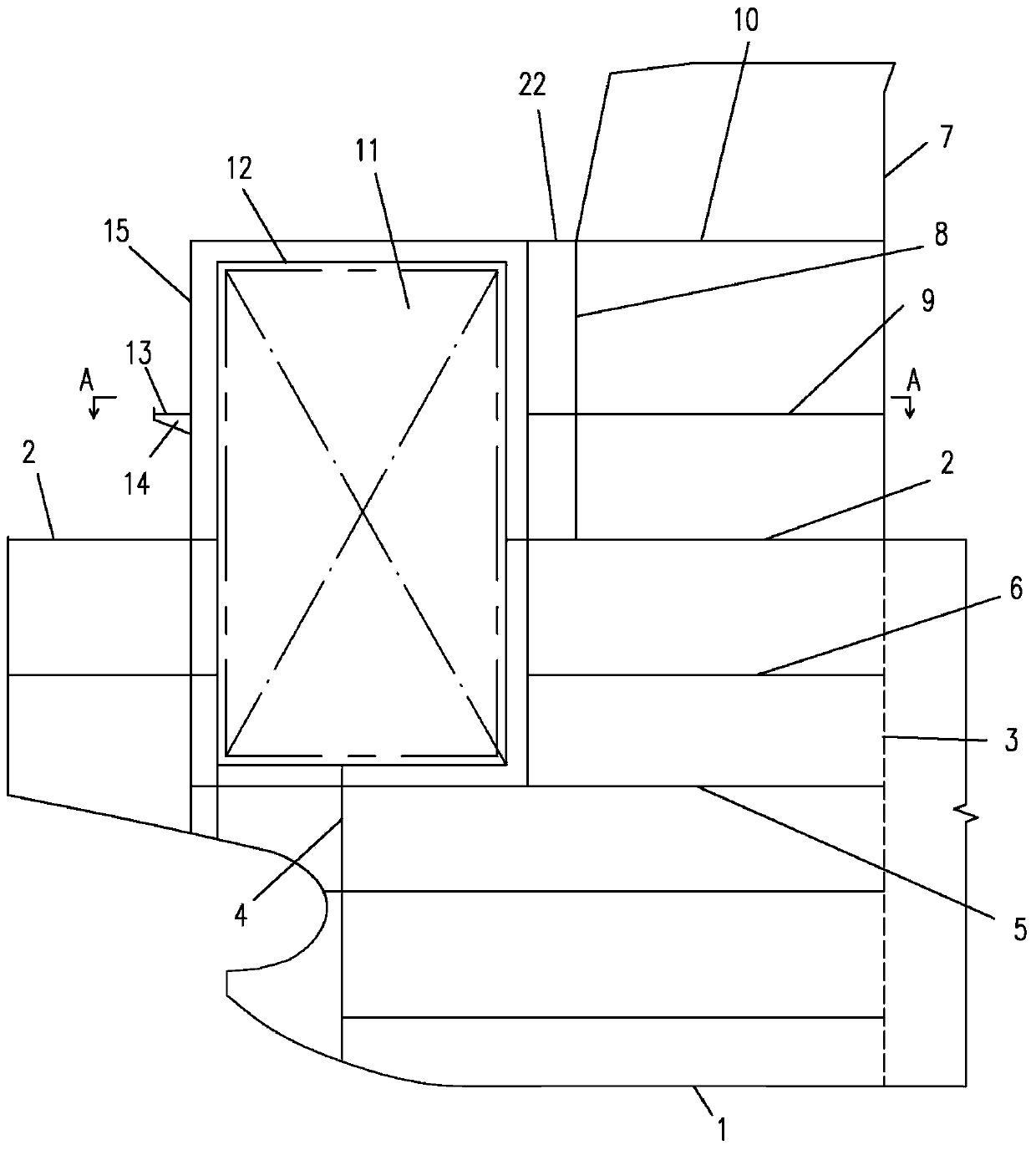

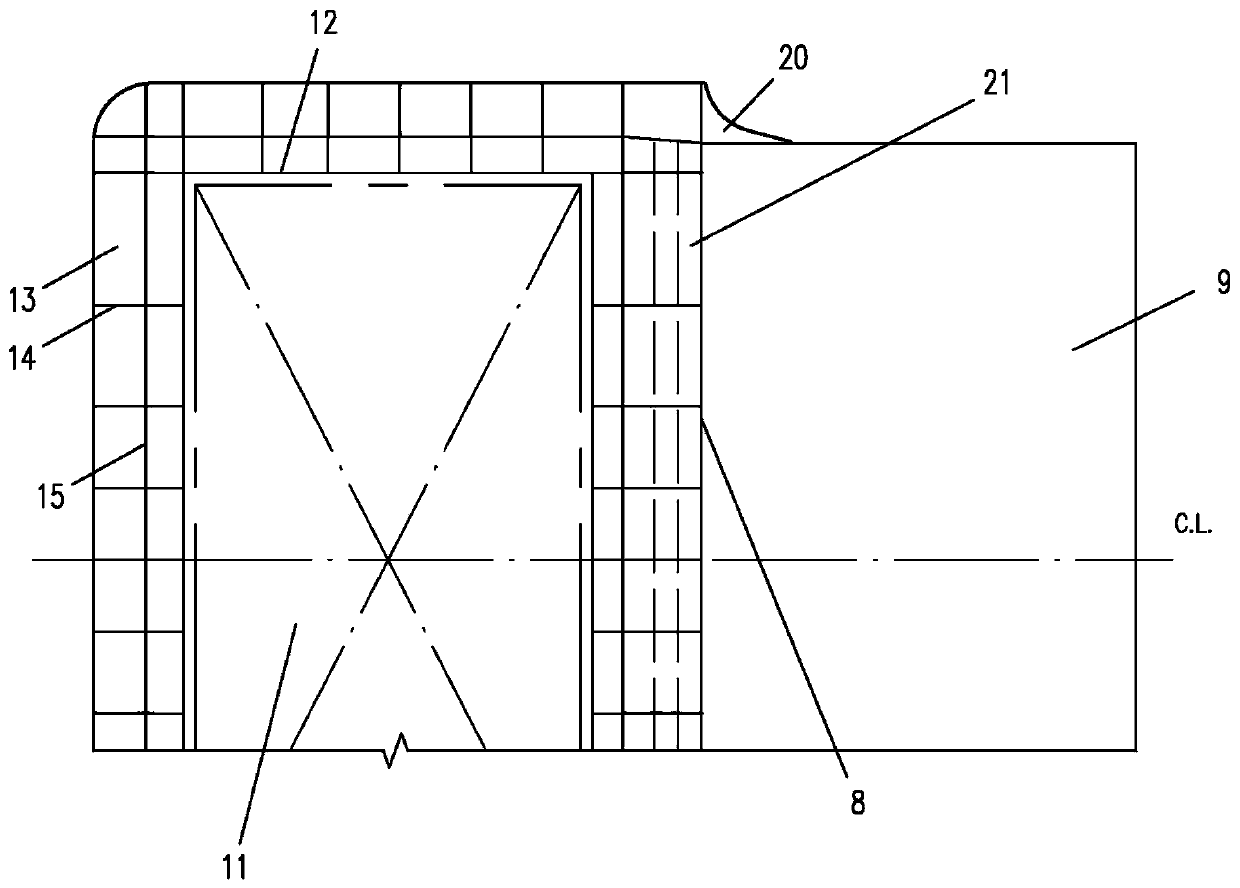

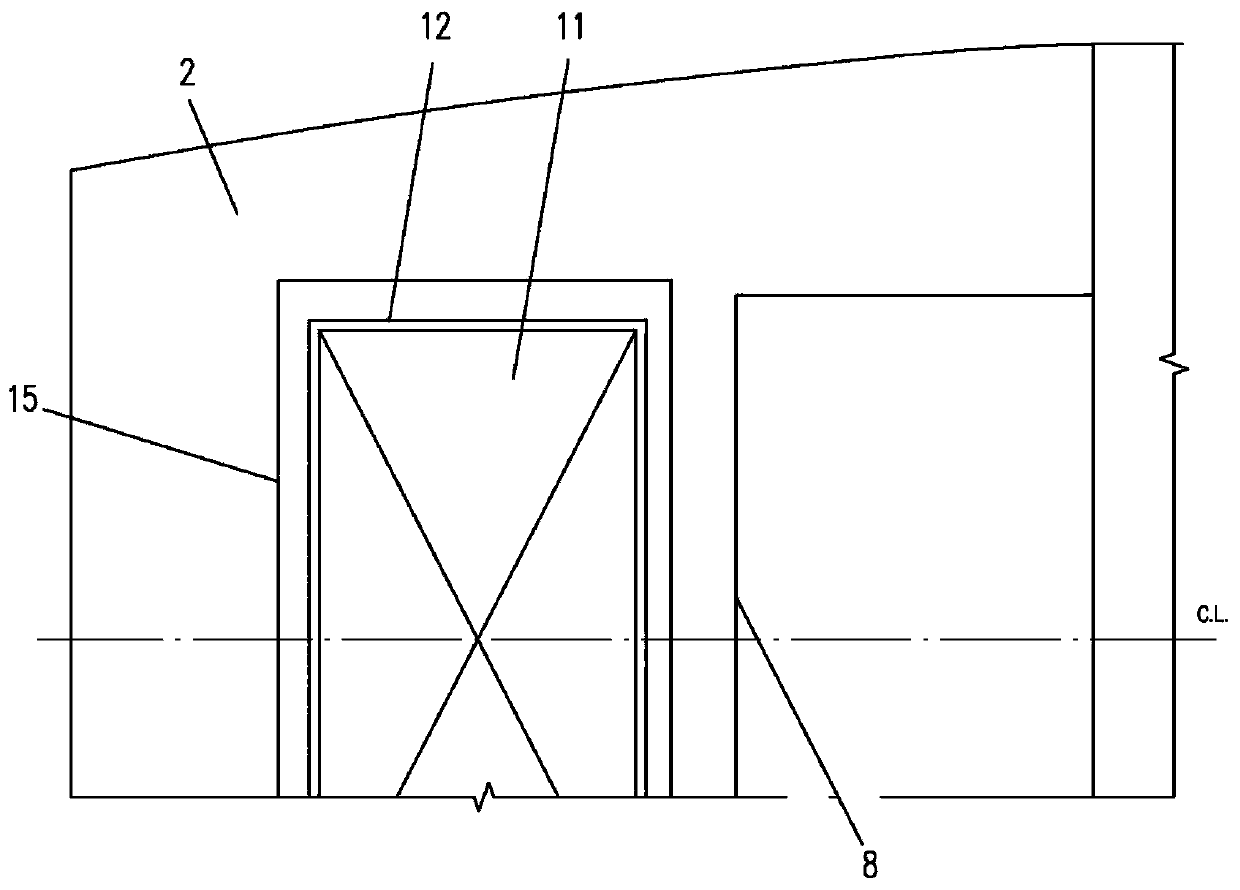

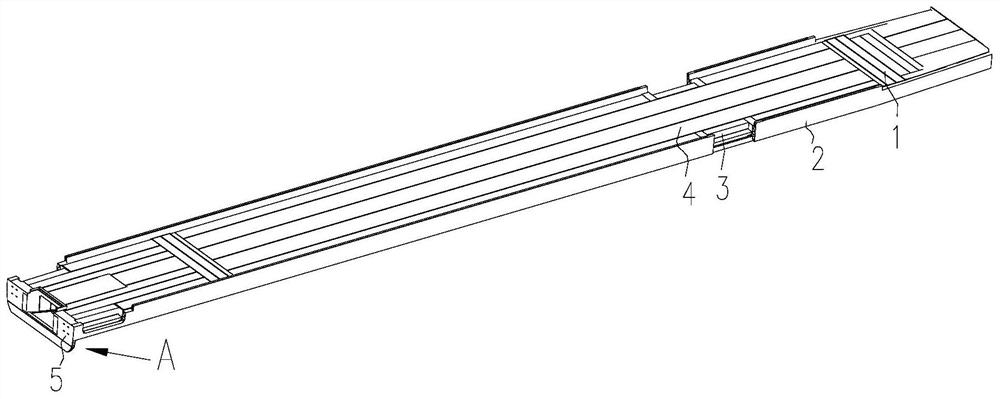

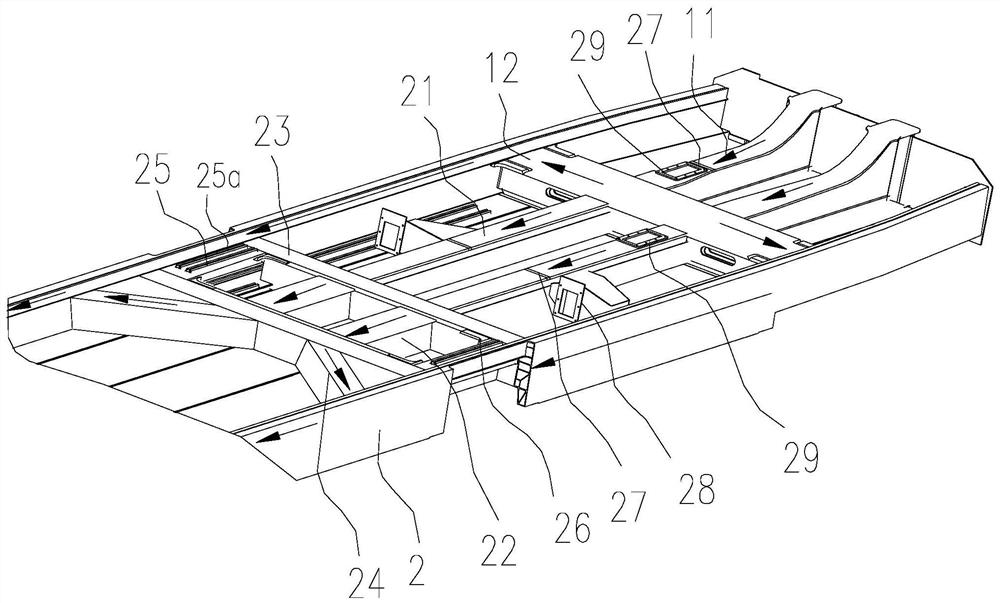

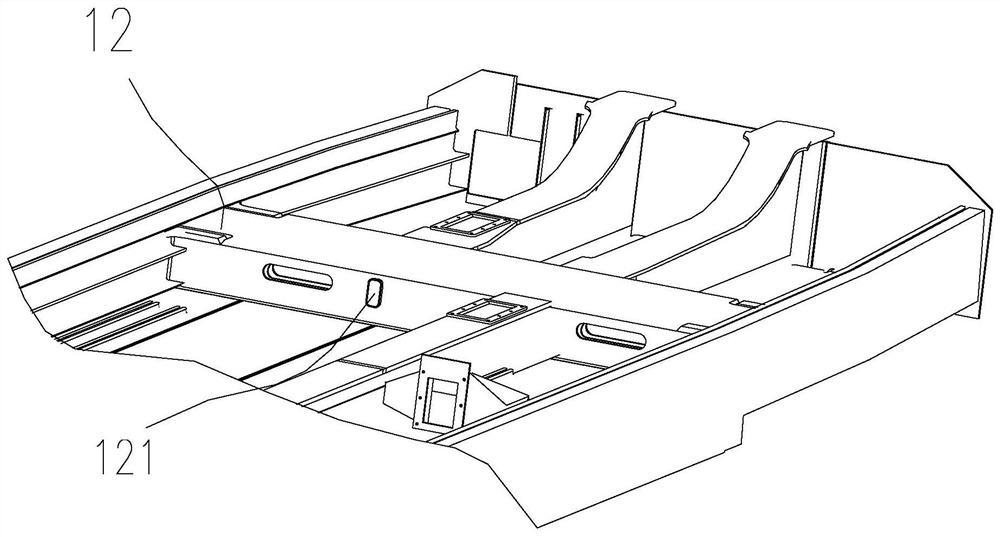

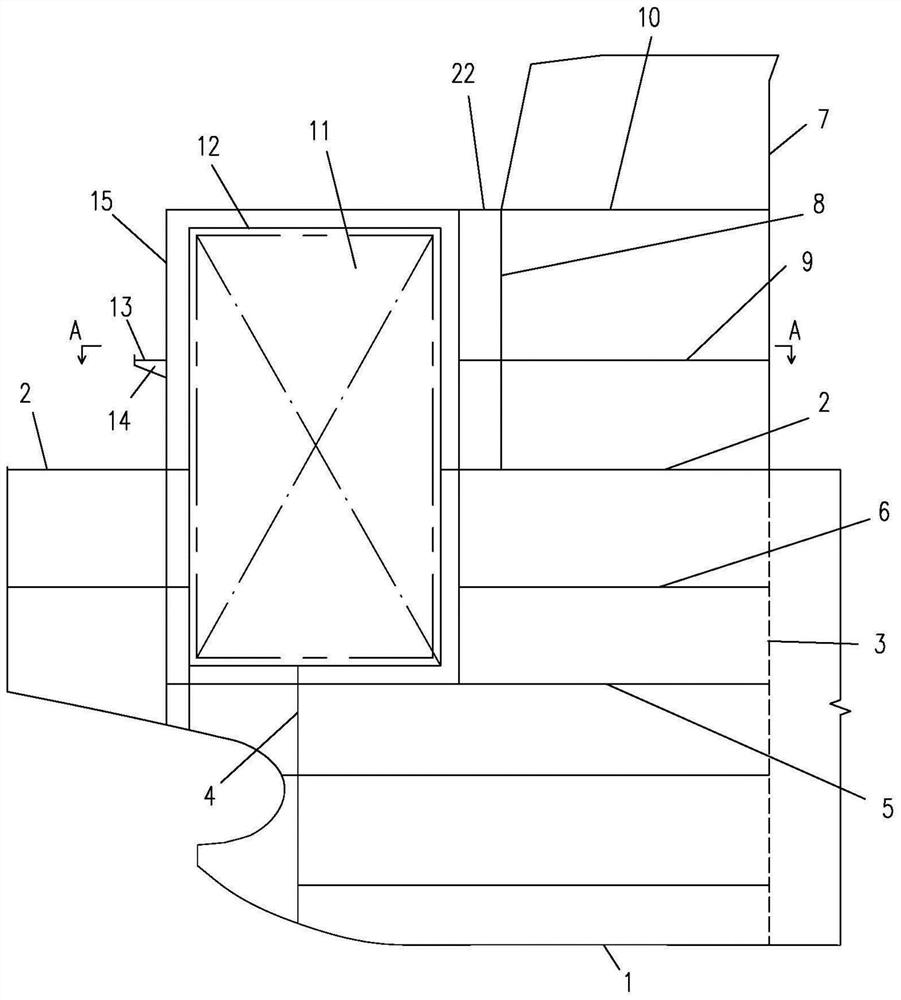

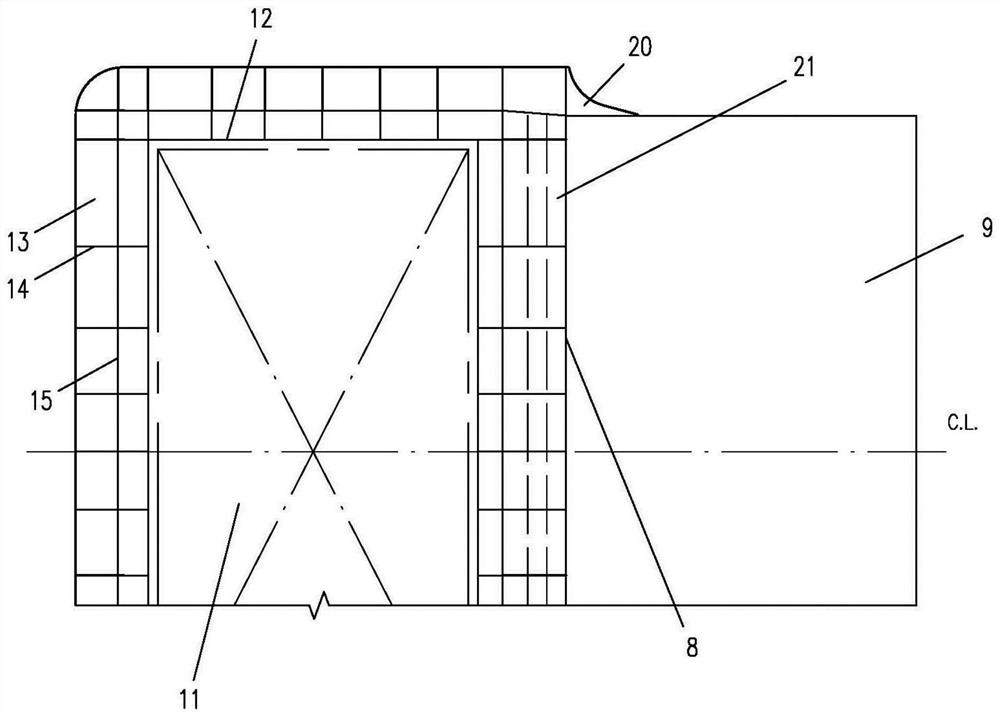

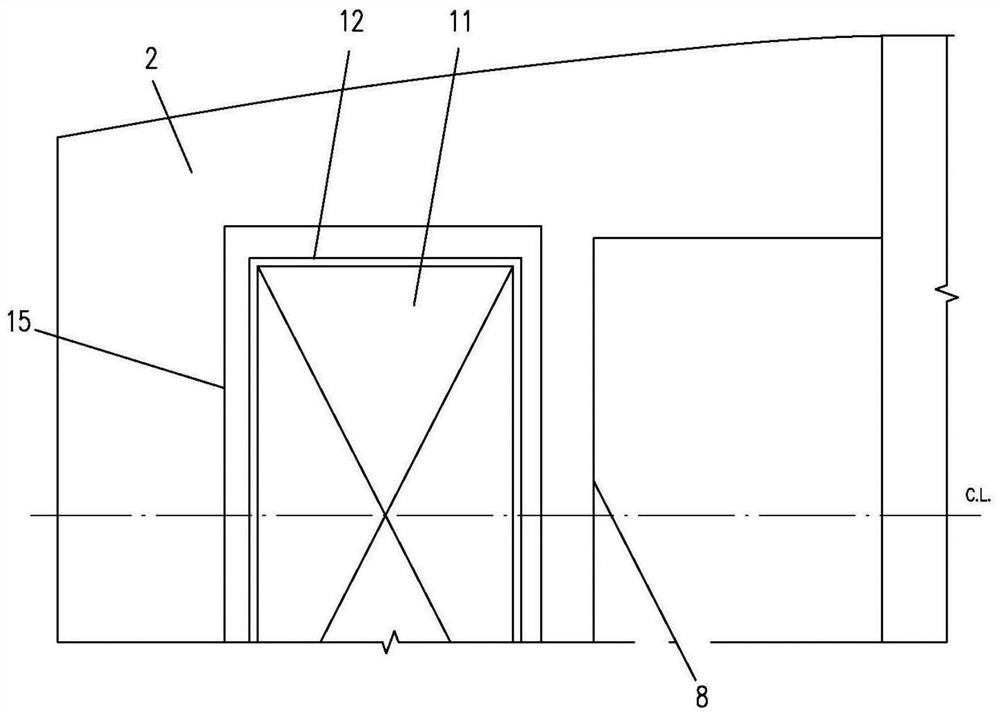

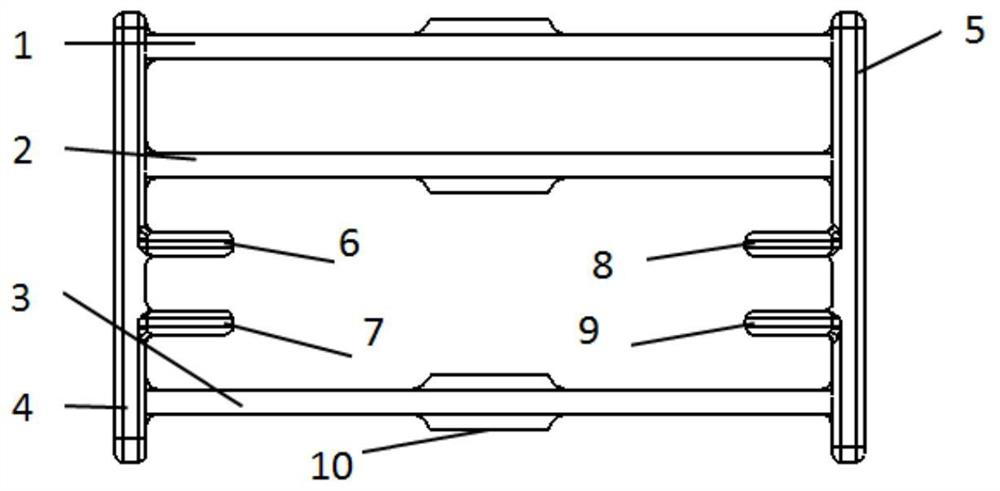

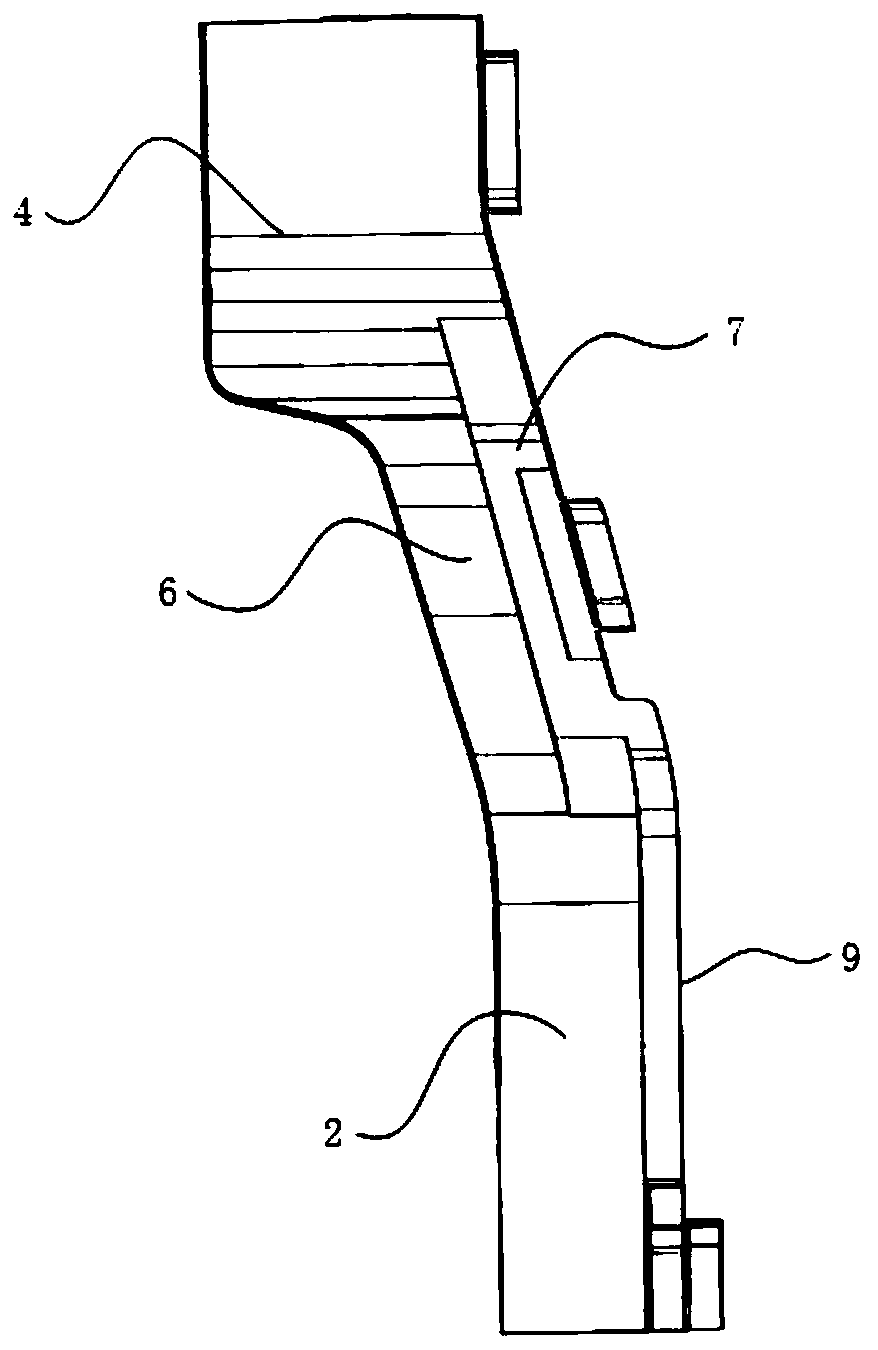

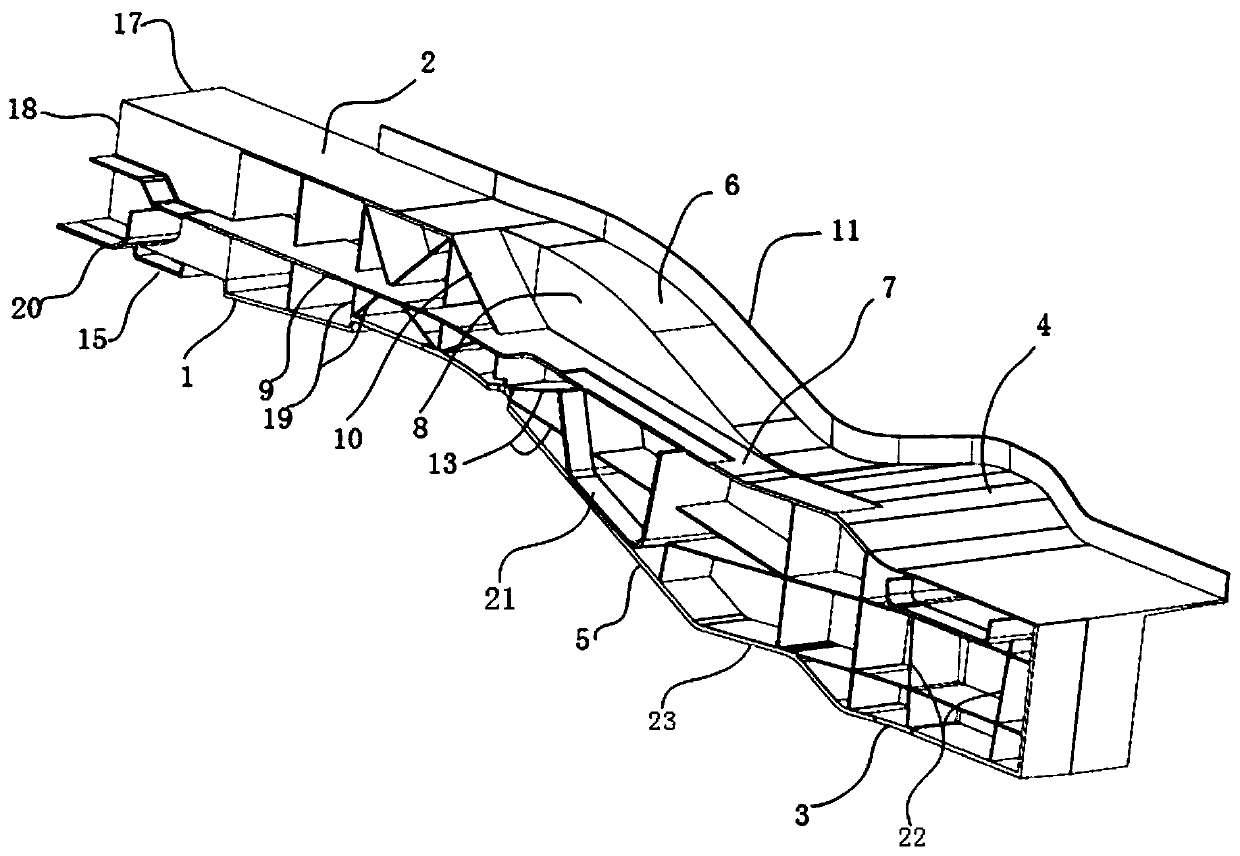

Railway vehicle and underframe structure thereof

ActiveCN110304091AImprove carrying capacityMeet collision requirementsBogiesCar doorBearing capacity

The invention discloses a railway vehicle and an underframe structure thereof. The chassis structure comprises underframe edge beams, a floor, an end beam, a first sleeper beam, and a second sleeper beam, wherein the underframe edge beams are parallelly and oppositely arranged, and the end beam are arranged at one end of the structure. The upper portion of the middle part of the underframe edge beams is provided with a middle door hole, and the lower portion of the middle part of the underframe edge beams is provided with a mounting cavity, wherein the mounting cavity is used for mounting mobile pedals. A stair reinforcing device comprises cross beams, a short longitudinal beam and a long longitudinal beam, wherein the cross beams are arranged on the two sides of the middle door hole and used for connecting the two oppositely-arranged underframe edge beams, and the upper portions of the cross beams are in plug-in connection with the floor. The short longitudinal beam is connected to the cross beams at two sides, the long longitudinal beam is connected with the first sleeper beam and the cross beam corresponding to one side of the first sleeper beam, and the distance from the firstsleeper beam to the cross beam corresponding to one side of the first sleeper beam is not greater than that from the second sleeper beam to the cross beam corresponding to one side of the second sleeper beam. According to the railway vehicle and the underframe structure thereof, due to the force transfer between the long longitudinal beam, the cross beams and the short longitudinal beam, the bearing capacity, especially anti-longitudinal impact capacity, of underframe edge beams at the portion of the middle door hole is improved, thus meeting collision requirements when accidental collision occurs between vehicles; in addition, the problem of insufficient strength and rigidity in a middle-arranged vehicle door and a stair rear underframe structure can be solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

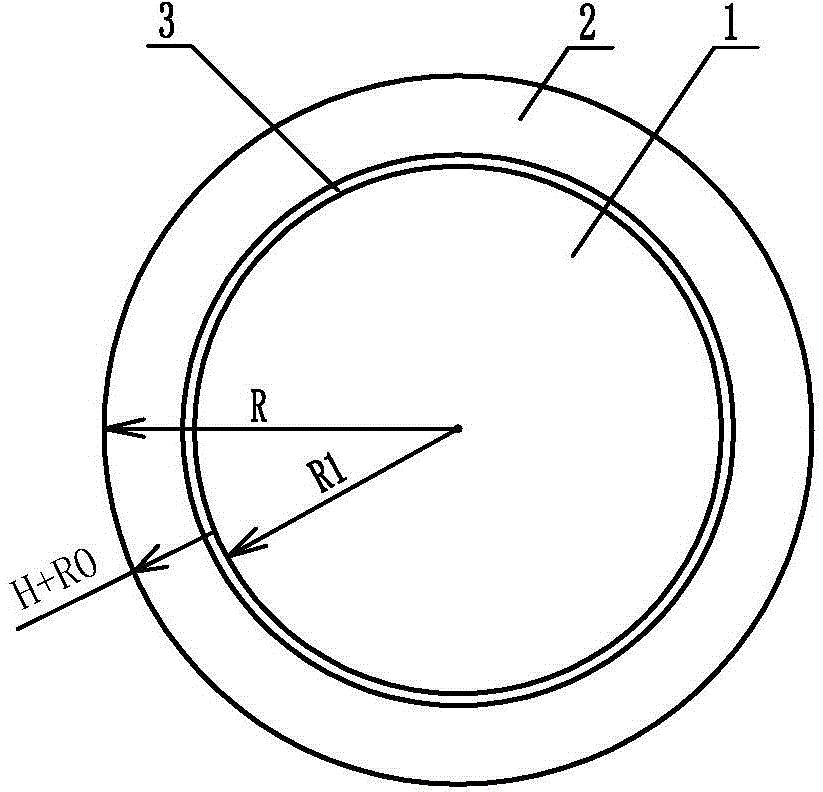

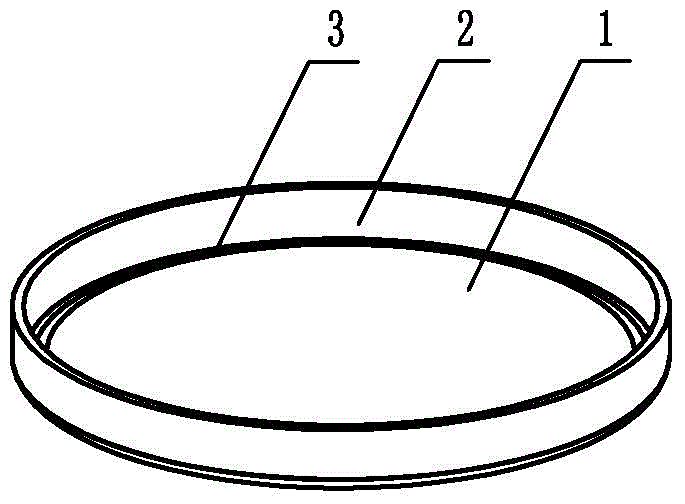

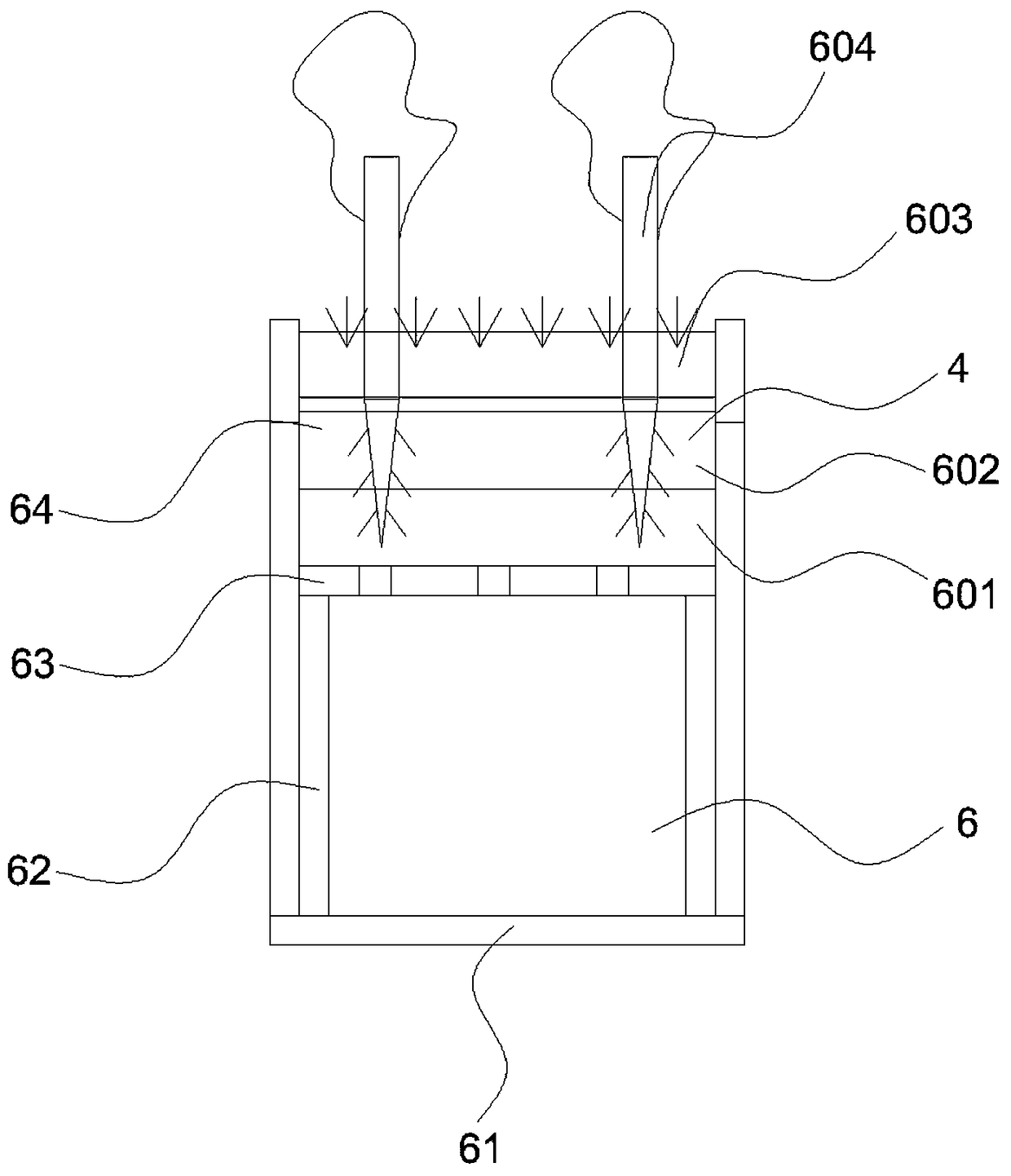

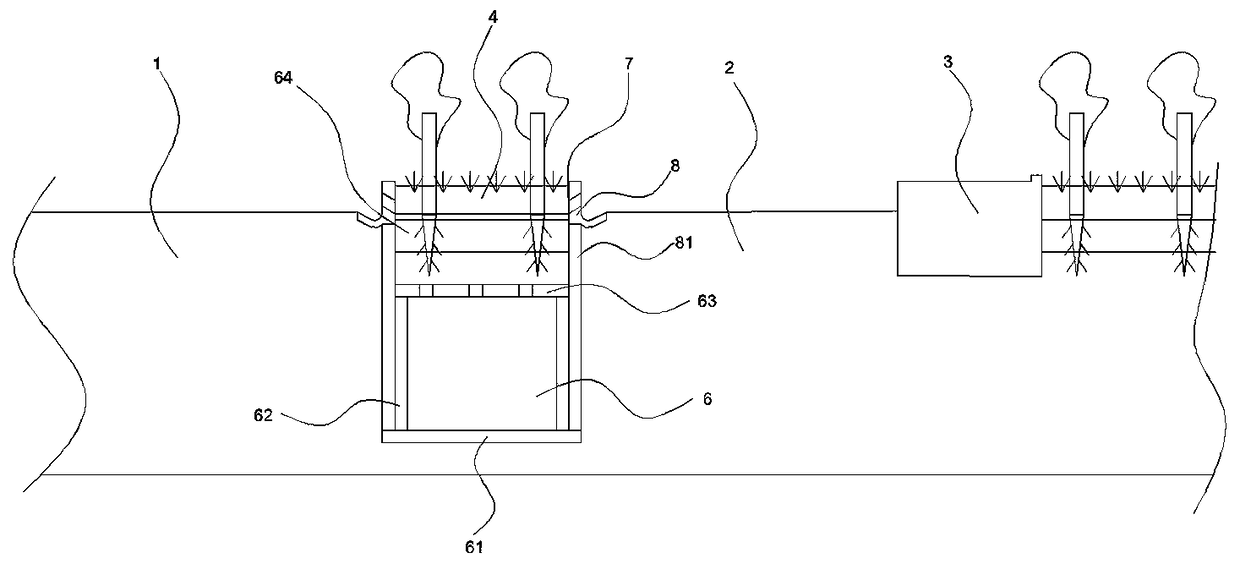

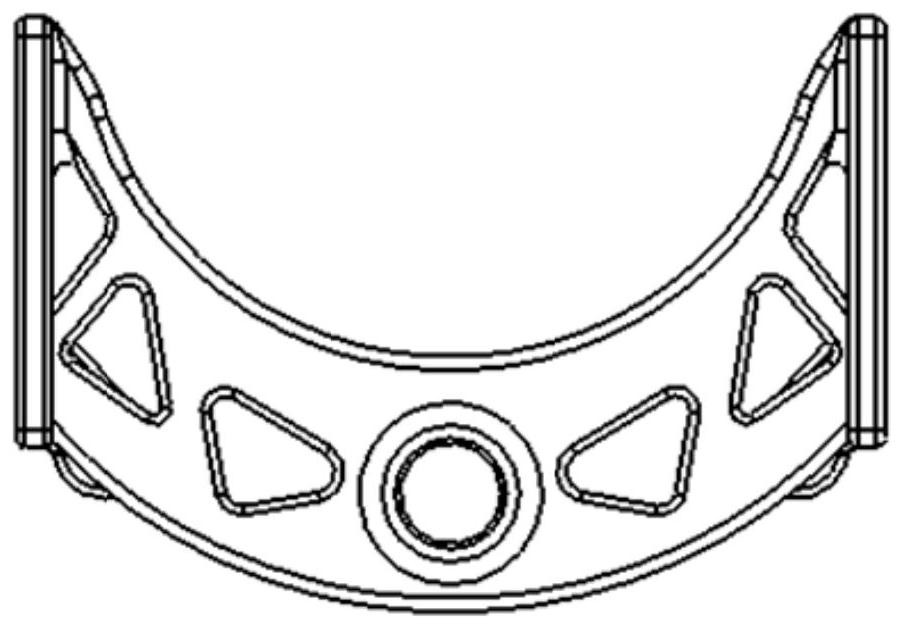

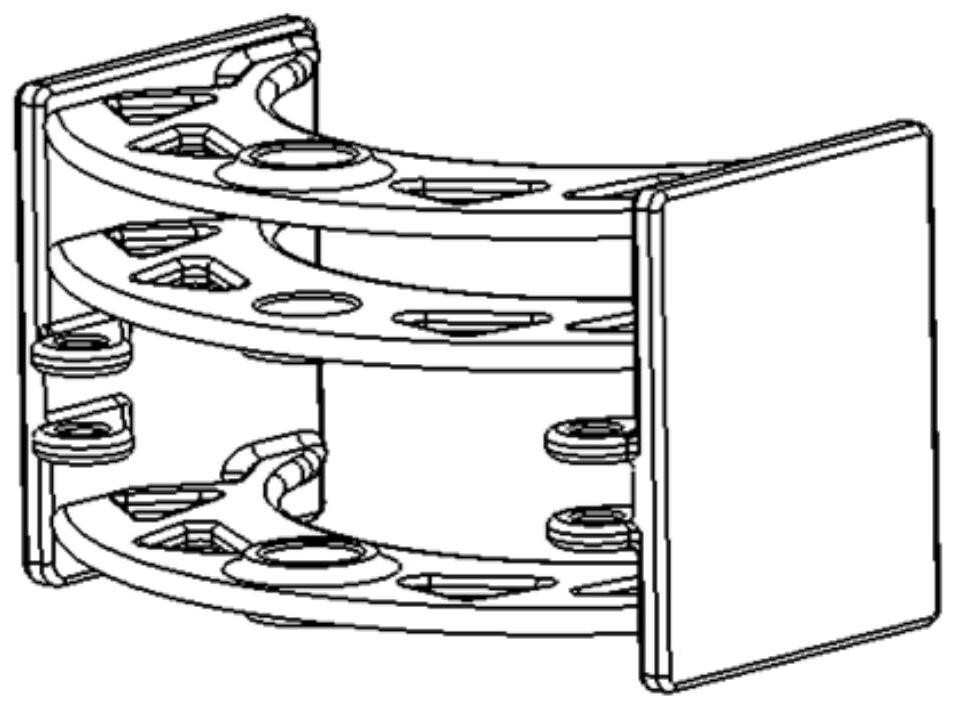

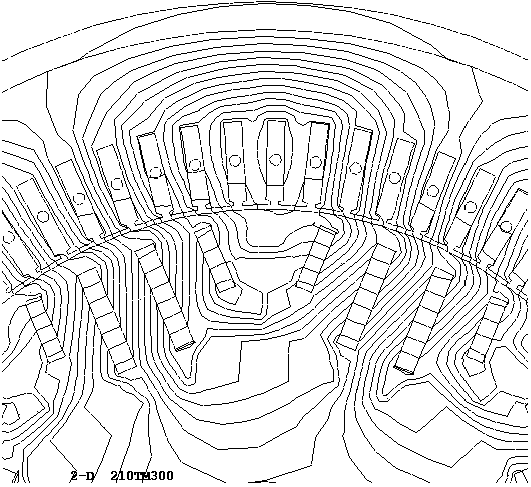

Bulk cargo ship liquefied natural gas bunker arrangement structure

ActiveCN110789663ASolve the problem of insufficient support strengthAddress structural strengthHull interior subdivisionFor bulk goodsBulk cargoBunker

The invention discloses a bulk cargo ship liquefied natural gas bunker arrangement structure which comprises a liquefied natural gas bunker. The liquefied natural gas bunker includes an outer shell and an inner shell, the liquefied natural gas bunker is arranged behind a superstructure, the liquefied natural gas bunker is embedded on an upper deck, the top of the liquefied natural gas bunker is flush with a middle deck of the superstructure, and the bottom of the liquefied natural gas bunker is flush with a platform of an engine room; the outer shell of the liquefied natural gas bunker is fixedly provided with an overhanging T-beam; and a web of the overhanging T-beam is fixedly connected to the outer shell, and the web of the overhanging T-beam is flush with a lower deck of the superstructure. The bulk cargo ship liquefied natural gas bunker arrangement structure effectively solves the problem about structural strength of the fuel bunker and can be used on the lower platform of the engine room, the utilization ratio in the height direction is higher, and layout of the entire engine room is more optimized.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

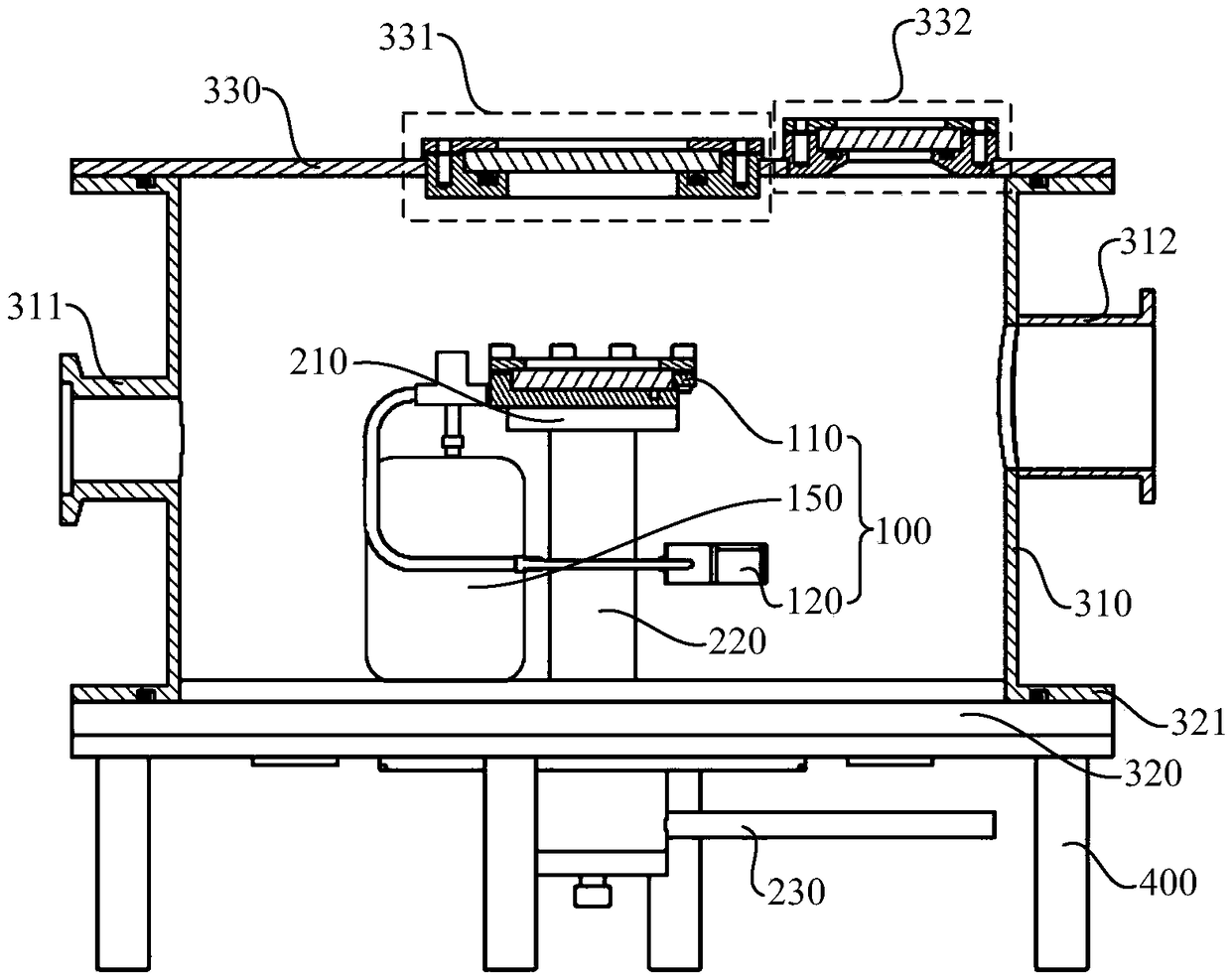

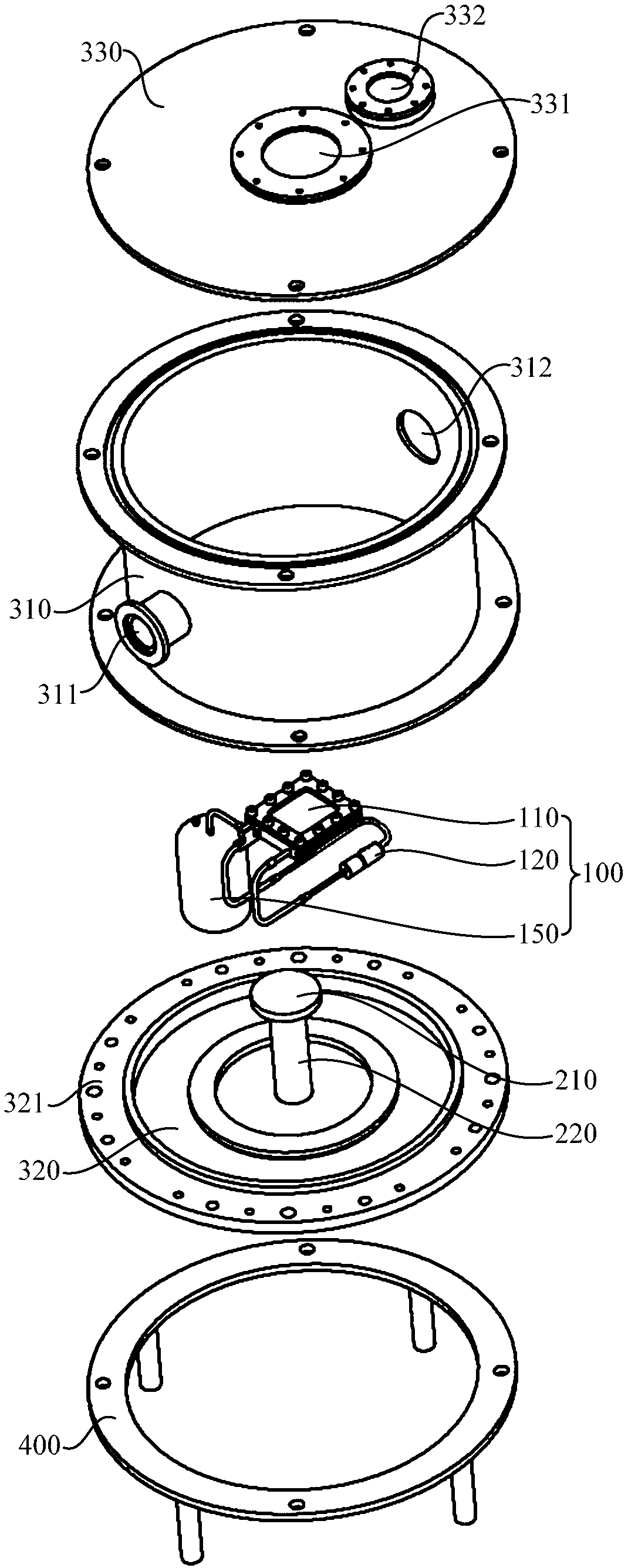

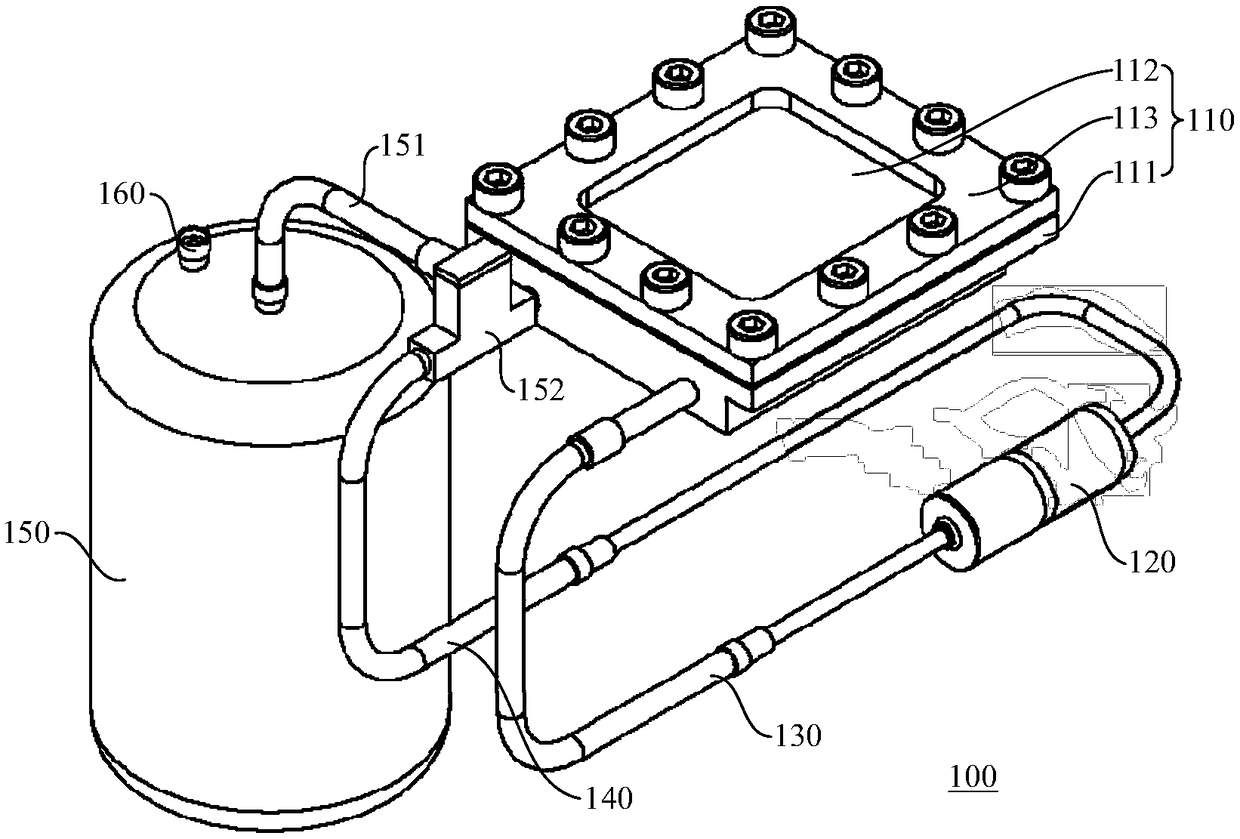

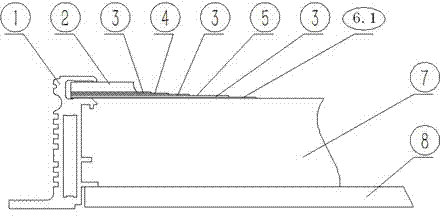

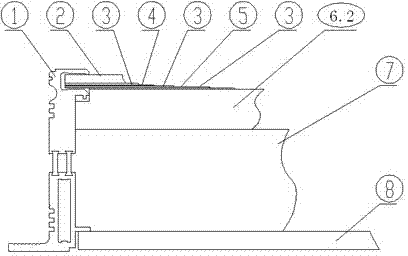

Visual experimental device for low-temperature fluid condensation and flow

PendingCN108645886AEasy to adjustReduced structural sealing difficultyFlow propertiesMaterial condensationLoop heat pipeEvaporator

The invention relates to the field of low-temperature fluid flow experiments and discloses a visual experimental device for low-temperature fluid condensation and flow. The visual experimental devicecomprises a loop heat pipe, a refrigerator in contact with a condenser and a heat insulation system surrounding at least part of the loop heat pipe and at least part of the refrigerator, wherein the loop heat pipe comprises the condenser and an evaporator which are in closed connection to form a loop; at least part of the heat insulation system is pervious to light the condenser comprises a bottomplate and a photo-permeable cover plate, channels are formed in the bottom plate, the photo-permeable cover plate is attached to the bottom plate and defines a condensation channel together with thechannels in the bottom plate. The visual experimental device for low-temperature fluid condensation and flow can visualize the condensation and flow process of low-temperature fluid, and the structural strength problem caused by cold and heat shock, large difference in thermal expansion coefficients of structural members and the like is also solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

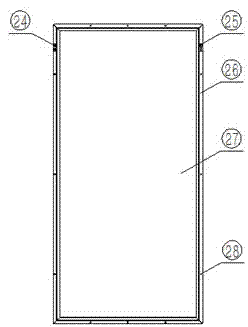

Damp-proof sound-absorbing building envelope with air layer

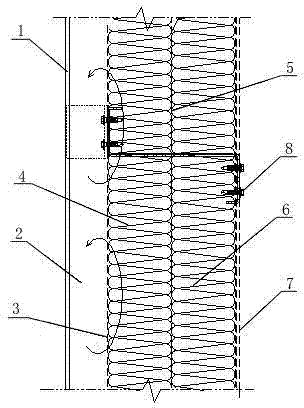

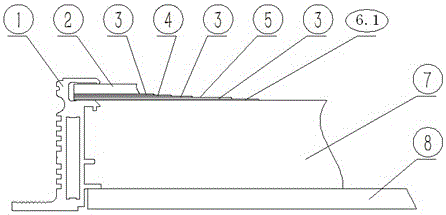

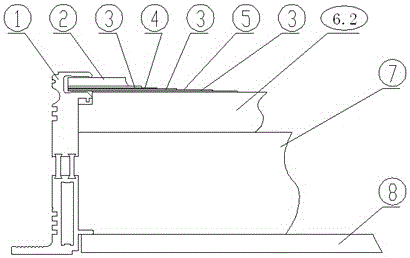

ActiveCN103485447AAvoid moisture accumulationSolve the durability problemCovering/liningsWallsWater vaporEngineering

The invention discloses a damp-proof sound-absorbing building envelope with an air layer. The damp-proof sound-absorbing building envelope is characterized by comprising an exterior trimming panel, a heat-insulating waterproof layer, an outer layer flame-retardant sound-absorbing heat-insulating material layer, a vapor blocking layer, an inner layer flame-retardant sound-absorbing heat-insulating material layer and an interior trimming panel which are all arranged in sequence from the outside to the inside of a room. The air layer which is sealed relatively is formed between the exterior trimming panel and the heat-insulating waterproof layer. By the arrangement of the air layer and the matched design of the heat-insulating waterproof layer, the inner layer flame-retardant sound-absorbing heat-insulating material layer, the outer layer flame-retardant sound-absorbing heat-insulating material layer and the vapor blocking layer, humidity accumulation in a heat-insulating material can be effectively avoided, and the problem that the durability, structural strength and heat insulation of a heat insulation system are affected due to poor moisture penetrability in the heat insulation system is solved. The damp-proof sound-absorbing building envelope is clear in hierarchical structure and is good in heat insulation, energy saving performance, moisture penetrability, damp prevention and sound absorption, and the shortcoming that the building porous material external building envelope is internally easily affected with damp, condensation and mold and is non-breathable and poor in sound absorption can be fundamentally overcome.

Owner:CHINA SOUTHWEST ARCHITECTURAL DESIGN & RES INST CORP LTD

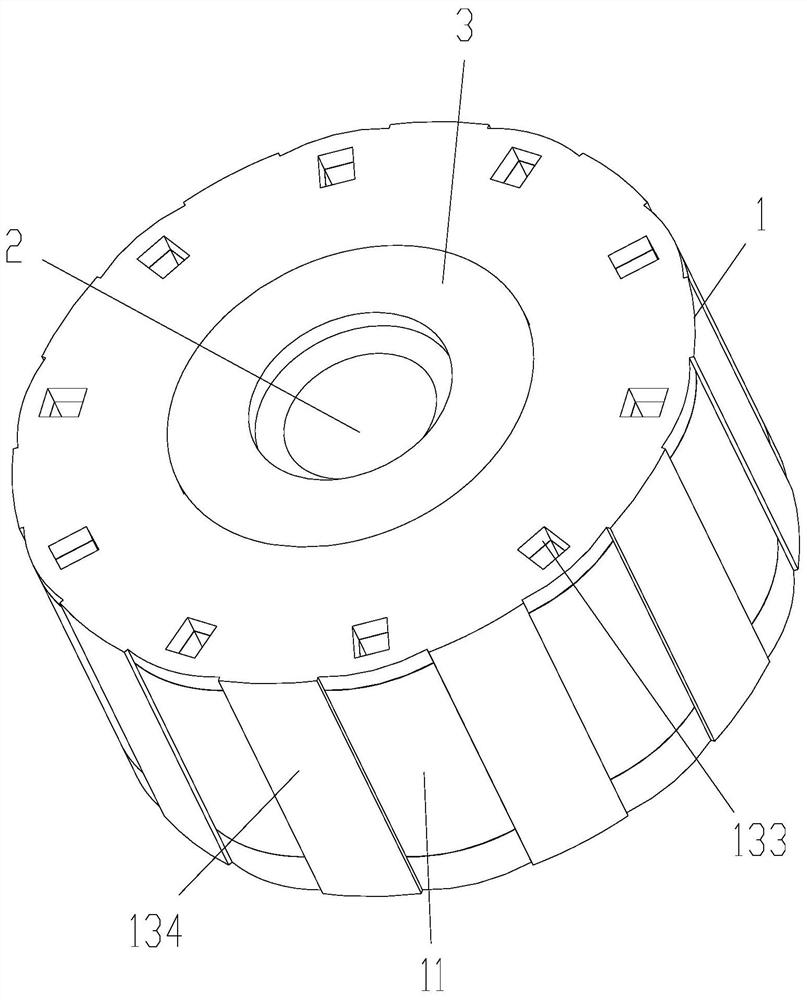

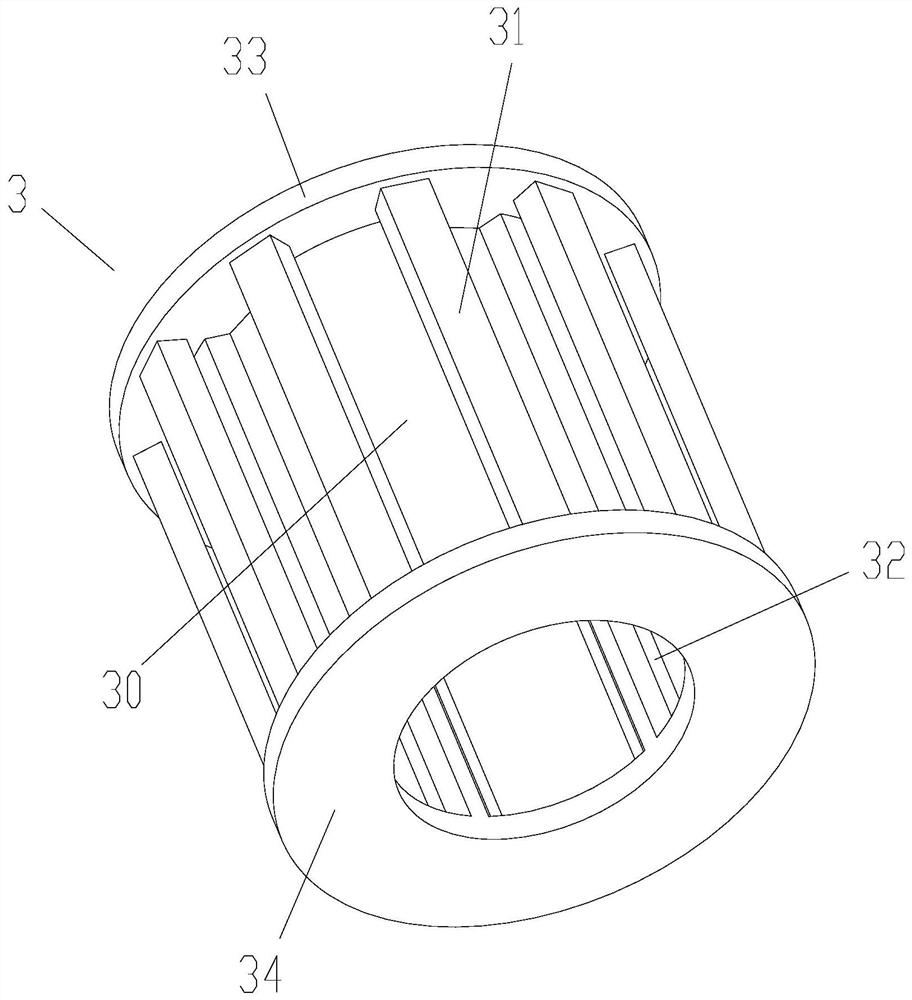

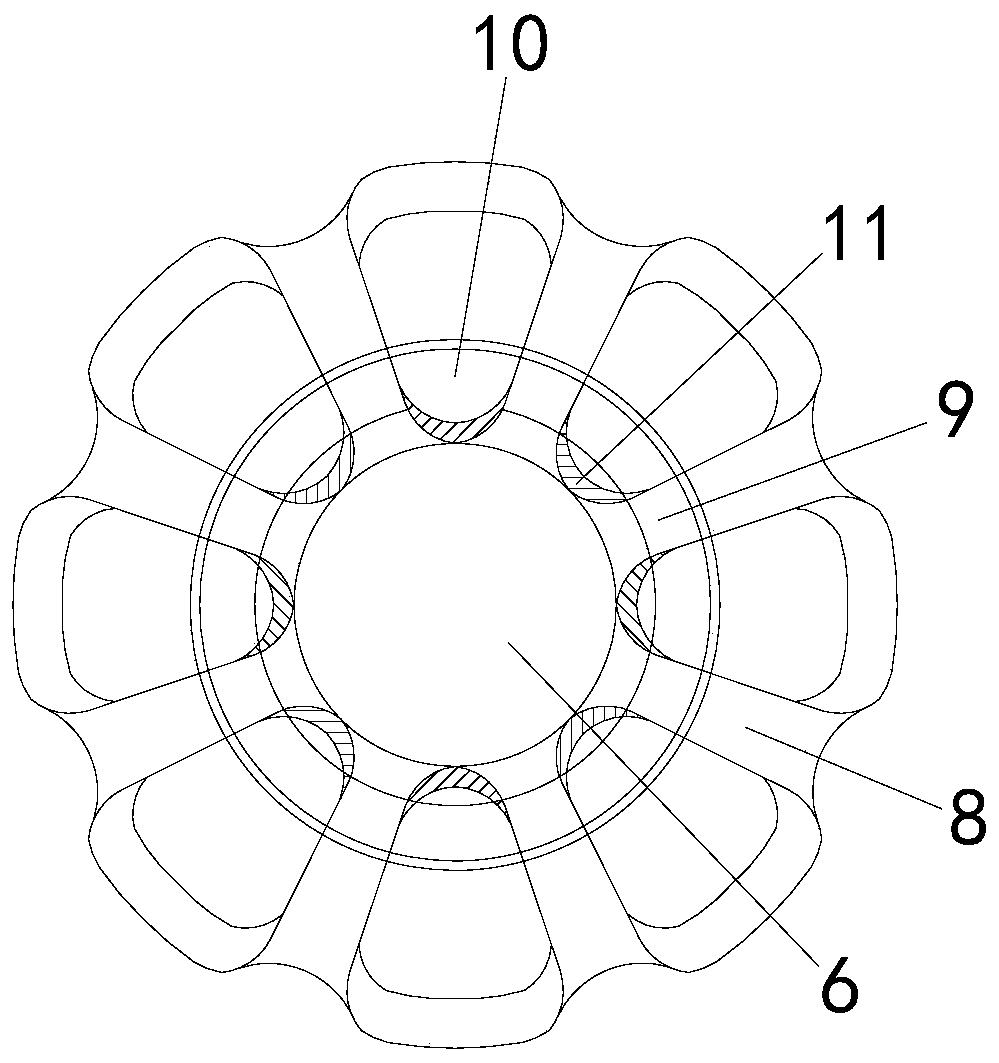

Rotor structure and motor

PendingCN112737170AImprove structural strengthAddress structural strengthMagnetic circuit rotating partsSupports/enclosures/casingsElectric machineEngineering

The invention provides a rotor structure and a motor, and the rotor structure comprises a body structure which comprises an outer iron core, a magnet, and a supporting frame, wherein the supporting frame is provided with a through hole and a plurality of first connecting holes formed in the direction surrounding the preset axis at intervals, and the plurality of first connecting holes, the outer iron core and the magnet are arranged at intervals; an inner iron core used for being connected with a shaft of the motor, wherein the inner iron core is installed in the through hole and is spaced from the body structure, and the inner iron core is provided with a plurality of second connecting holes which are formed at intervals in the direction surrounding the preset axis; a damping piece which is made of a deformable material, and comprises a damping part located in a gap between the inner iron core and the body structure, wherein the damping piece comprises a first connecting part and a second connecting part, the first connecting part is arranged in the first connecting hole in a penetrating mode, and the second connecting part is arranged in the second connecting hole in a penetrating mode. According to the rotor structure, the problem that the damping effect and the structural strength of a rotor structure in the prior art are difficult to consider is solved.

Owner:GREE ELECTRIC APPLIANCES INC

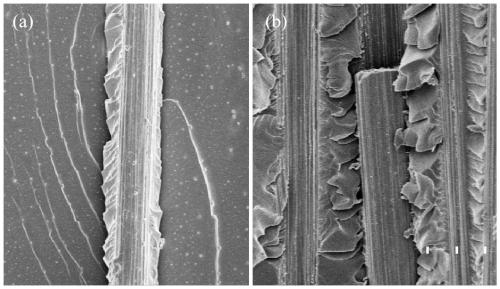

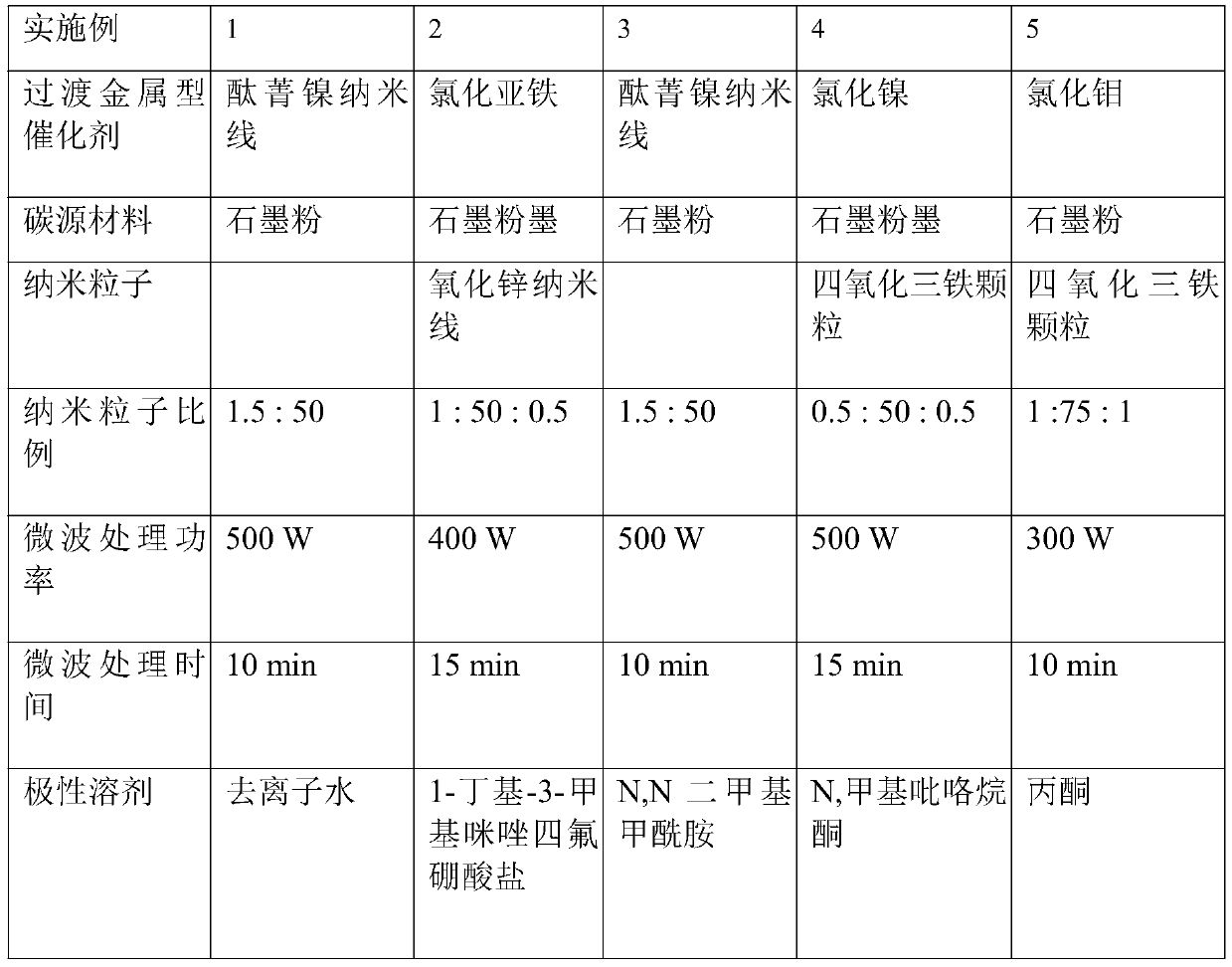

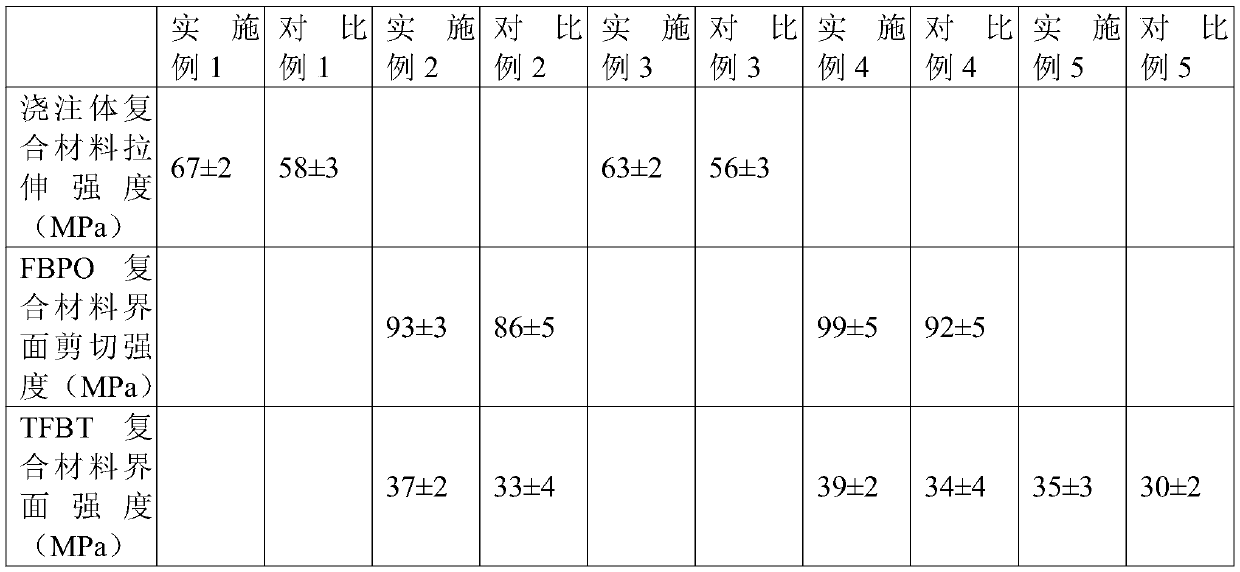

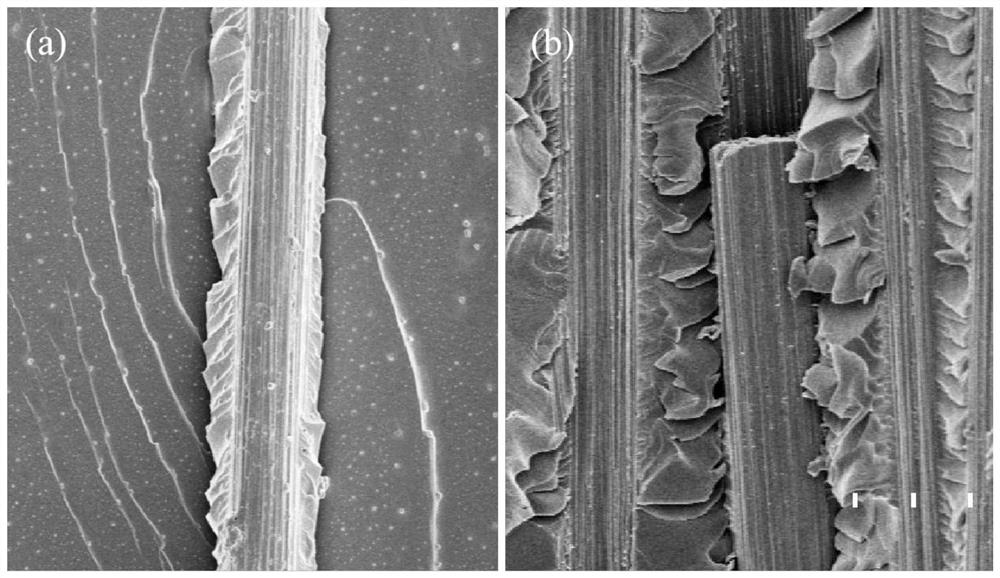

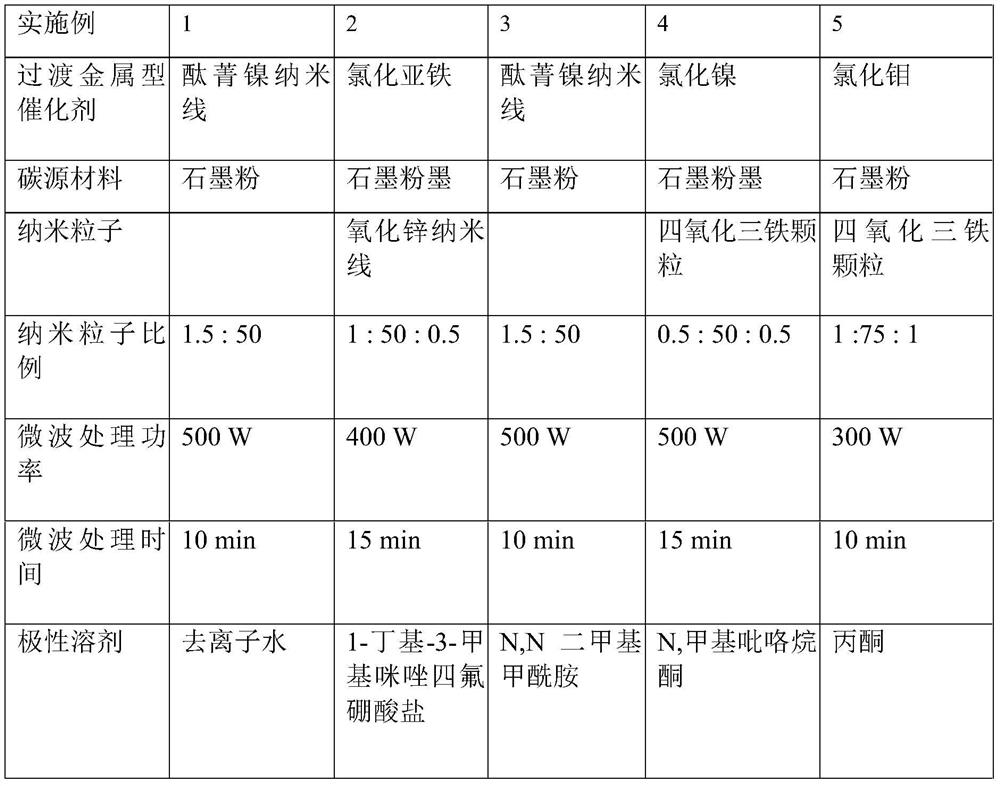

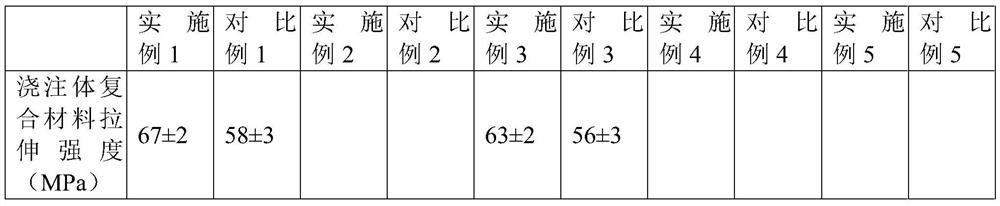

Microwave-assisted efficient construction method for high-strength interface of carbon-based reinforcement/resin composite material

The invention discloses a microwave-assisted efficient construction method for a high-strength interface of a carbon-based reinforcement / resin composite material, and belongs to the field of compositematerials. The method comprises the following step: modifying a carbon-based reinforcement by nanoparticles through a synergistic effect of physical coating and chemical grafting so as to form an interface (a cage-shaped interface structure) coated with a cage-shaped structure carbon source material shell. Based on the microwave irradiation activation principle, the activation of the carbon-basedreinforcement and the uniform self-assembly of the nanoparticles are realized by adjusting the ratio of the transition metal catalyst to the carbon source material to the nanoparticles. Compared withcomposite material traditional interface enhancement, the method of the invention is more efficient and faster, realizes the nanometer reinforcement of the interface of the carbon-based reinforcement / resin composite material, solves the problem that the structural integrity and strength of the carbon-based reinforcement are damaged by discharging and sparking of the carbon-based reinforcement ina microwave field, and has important significance in preparing the high-performance carbon-based reinforcement / resin composite material; and the high-strength interface can be applied to the high-techfields of composite material pressure containers, aerospace crafts and the like.

Owner:BEIJING UNIV OF CHEM TECH

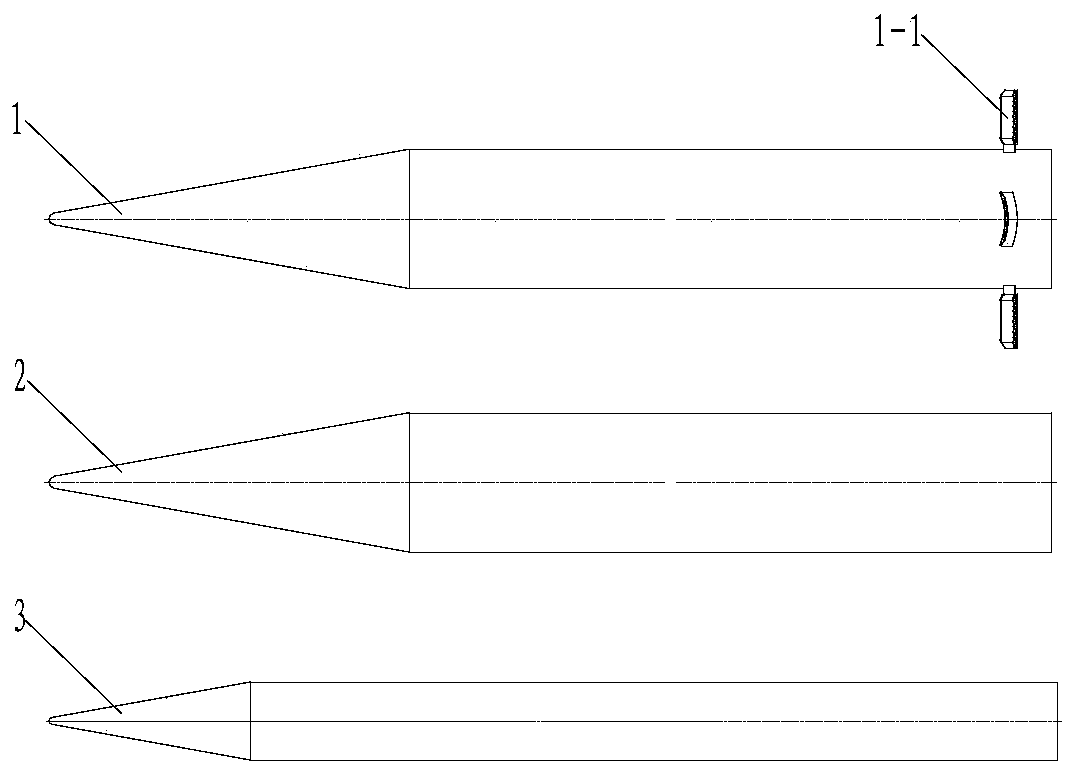

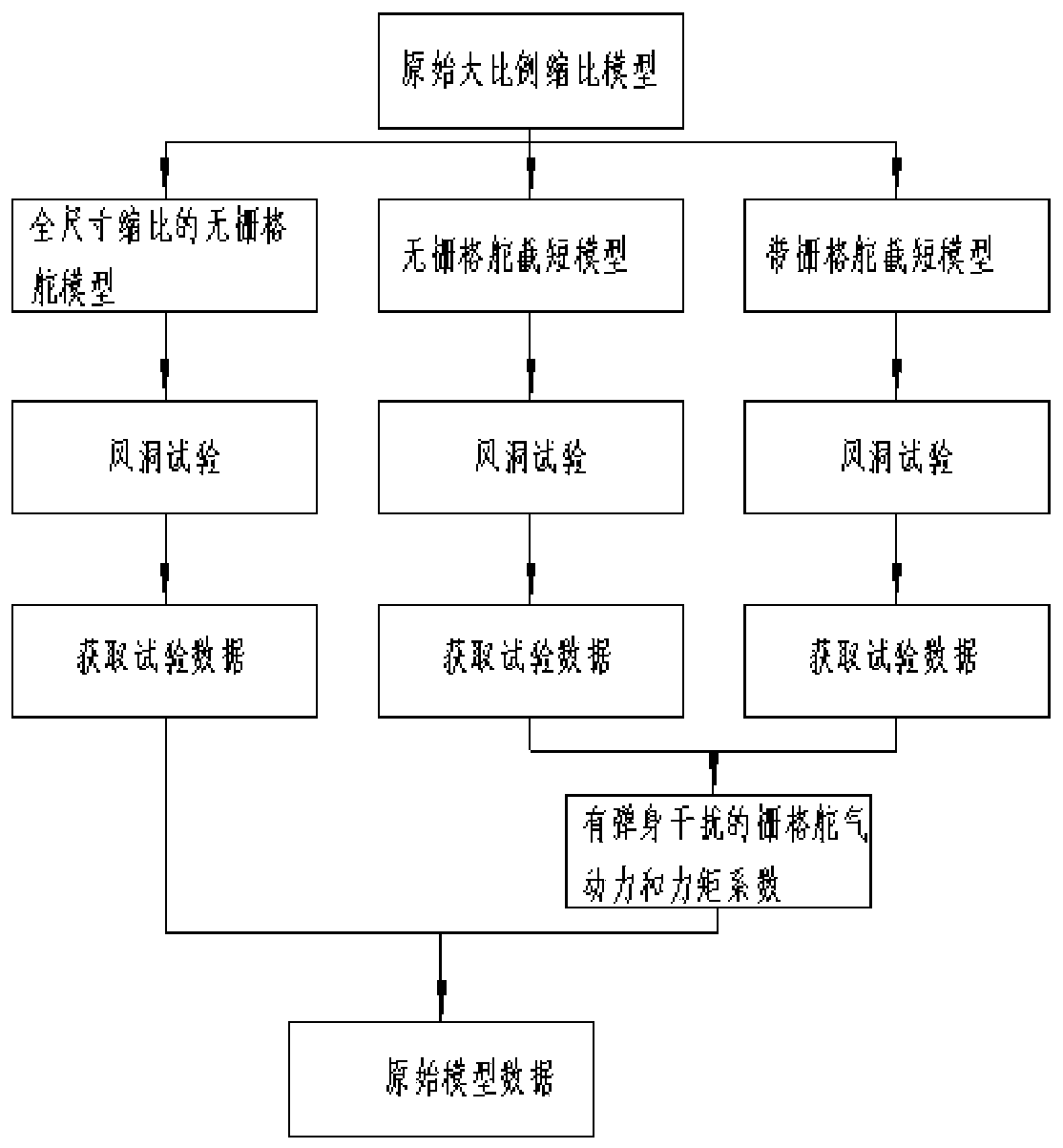

High-speed wind tunnel test simulation method for large-scaling grid rudder

ActiveCN111006845APrioritize model sizeStructural strength unchangedAerodynamic testingScale modelClassical mechanics

The invention relates to a high-speed wind tunnel test simulation method for a large-scaling grid rudder. The method comprises the steps: building three scaling models that meet wind tunnel test conditions and include a truncation model with a grid rudder, a truncation model without a grid rudder, and a full-size scale type model without a grid rudder according to an original large-slenderness-ratio grid rudder model; arranging the three scaling models respectively in a wind tunnel for simulation test under the condition of using unified balance systems to ensure the measurement precision; andacquiring test data of the three models through a wind tunnel test, processing the test data, and finally acquiring data of the original model. For the model with a large slenderness ratio and a longequal straight section, the truncation model with the grid rudder is designed, so that the model size of the grid rudder is preferentially guaranteed; meanwhile, the length of the model meets the wind tunnel test requirement, the aerodynamic characteristics of the grid rudder before and after truncation are basically unchanged, so that the machining problem and the structural strength problem encountered by a large-scale scaling grid rudder model are effectively solved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Solar member for building

ActiveCN104333302AReduce the temperatureAlleviate hot spotsPhotovoltaic supportsPhotovoltaic energy generationBuilding integrationCollector device

The invention relates to a solar member for a building. The solar member comprises a photovoltaic assembly, a junction box, a connector, a frame, a filling material and a member backboard. A solar heat collector or a metal plate is employed as a photovoltaic assembly backboard, and a heating electronic device and the frame or the photovoltaic assembly backboard are contacted for heat dissipation; the photovoltaic assembly and the member backboard are installed in a fixation groove corresponding to the frame to form an enclosed space, and an integral member module is formed by bonding the filling material; the outer side surface of the frame is provided with a radiator and a heat conduction pipe for conducting solar energy to a solar heat collection system; and a refrigeration and heating apparatus is integrated on the photovoltaic assembly backboard and the member backboard, and an isolation layer is clamped between the photovoltaic assembly backboard and the member backboard. According to the invention, the solar member for the building can be used for photovoltaic generating and solar heat collection and temperature adjustment, can directly replace a decoration material, an insulation material, a waterproof material, an exterior-protected construction material and an air conditioning device on the roof or the wall of the building, and can also be integrally installed with the roof or the wall of an existing building so as to realize photovoltaic building integration.

Owner:ANHUI CHANGYUAN GREEN ENERGY

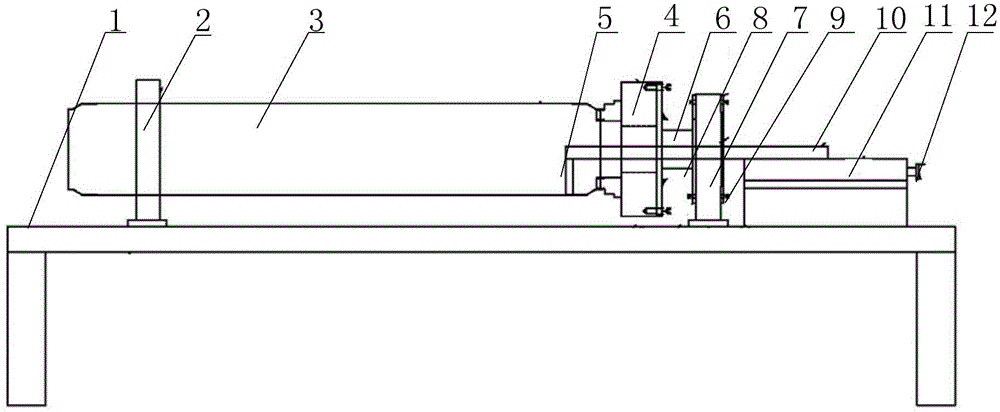

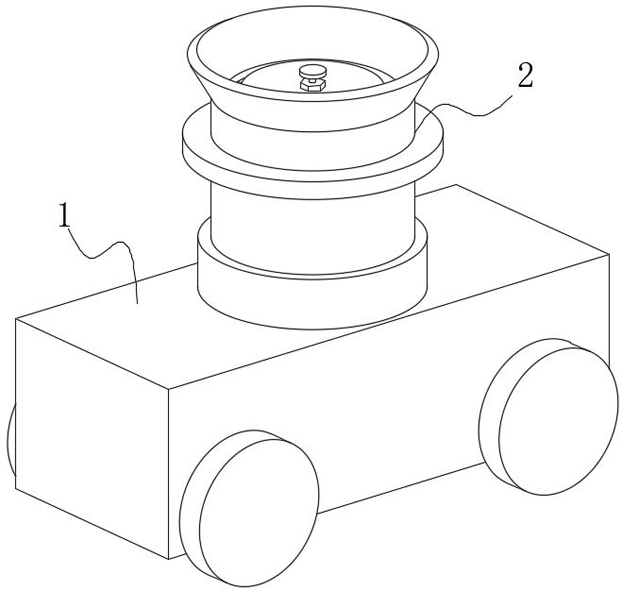

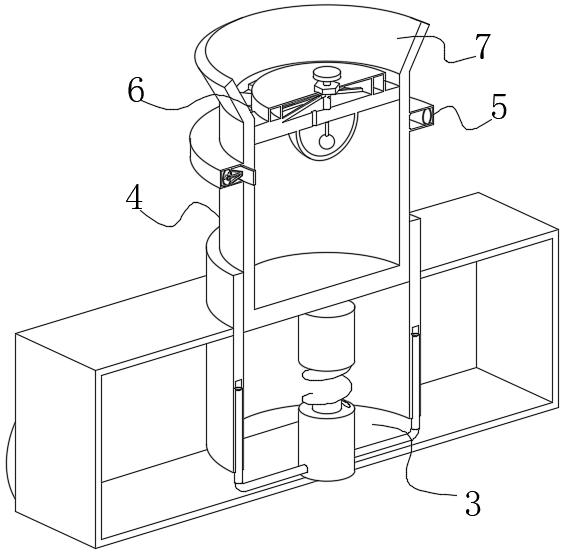

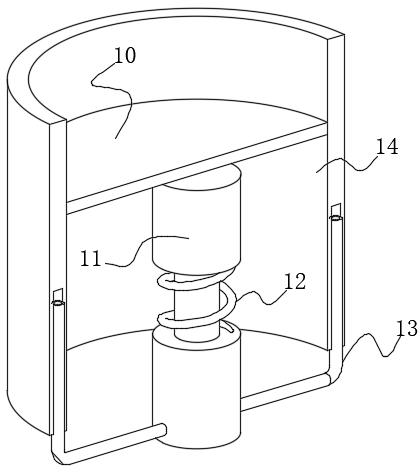

Choke plug stripping machine

The invention provides a choke plug stripping machine, comprising a choke plug chuck, a rotary shaft, a stripping cutting head, a circular mesh bracket and a bearing seat, wherein the circular mesh bracket supports a circular mesh of which the choke plug needs to be dismounted; the rotary shaft is arranged on the bearing seat, and is connected with the choke plug chuck; the choke plug chuck can clamp the inner circular surface of the choke plug, and drives the choke plug to rotate; the stripping cutting head can clamp the axial inner side of the choke plug along a nickel mesh, and applies an action force on the choke plug in the axial direction of the circular mesh. According to the choke plug stripping machine, the inner side of the circular mesh is clamped through the stripping cutting head, so that the 360-degree rotation of the choke plug is realized by utilization of the choke plug chuck; the stripping cutting head continuously applies a stripping force on different circumferential parts at the inner side of the choke plug, so that the choke plug is stripped from the circular mesh.

Owner:YUYUE HOME TEXTILE

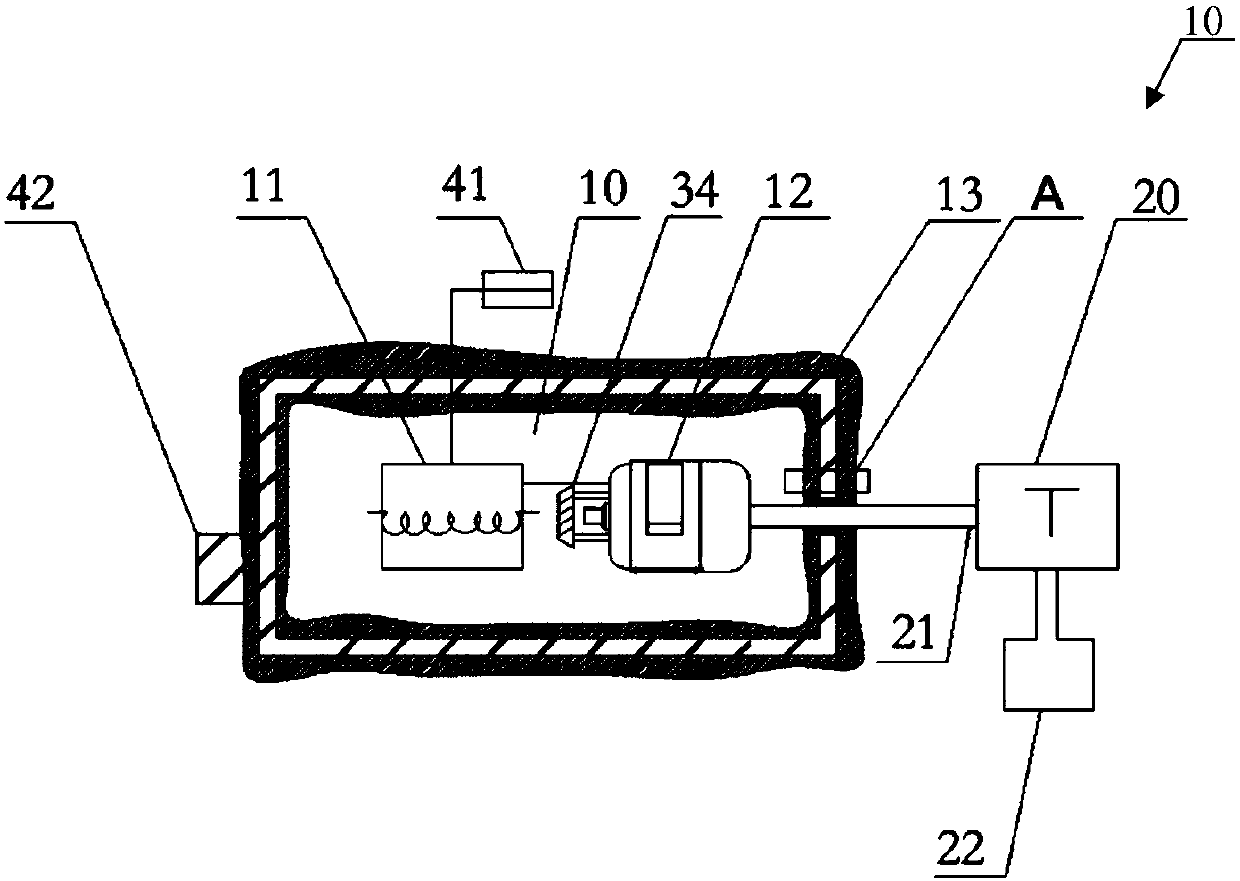

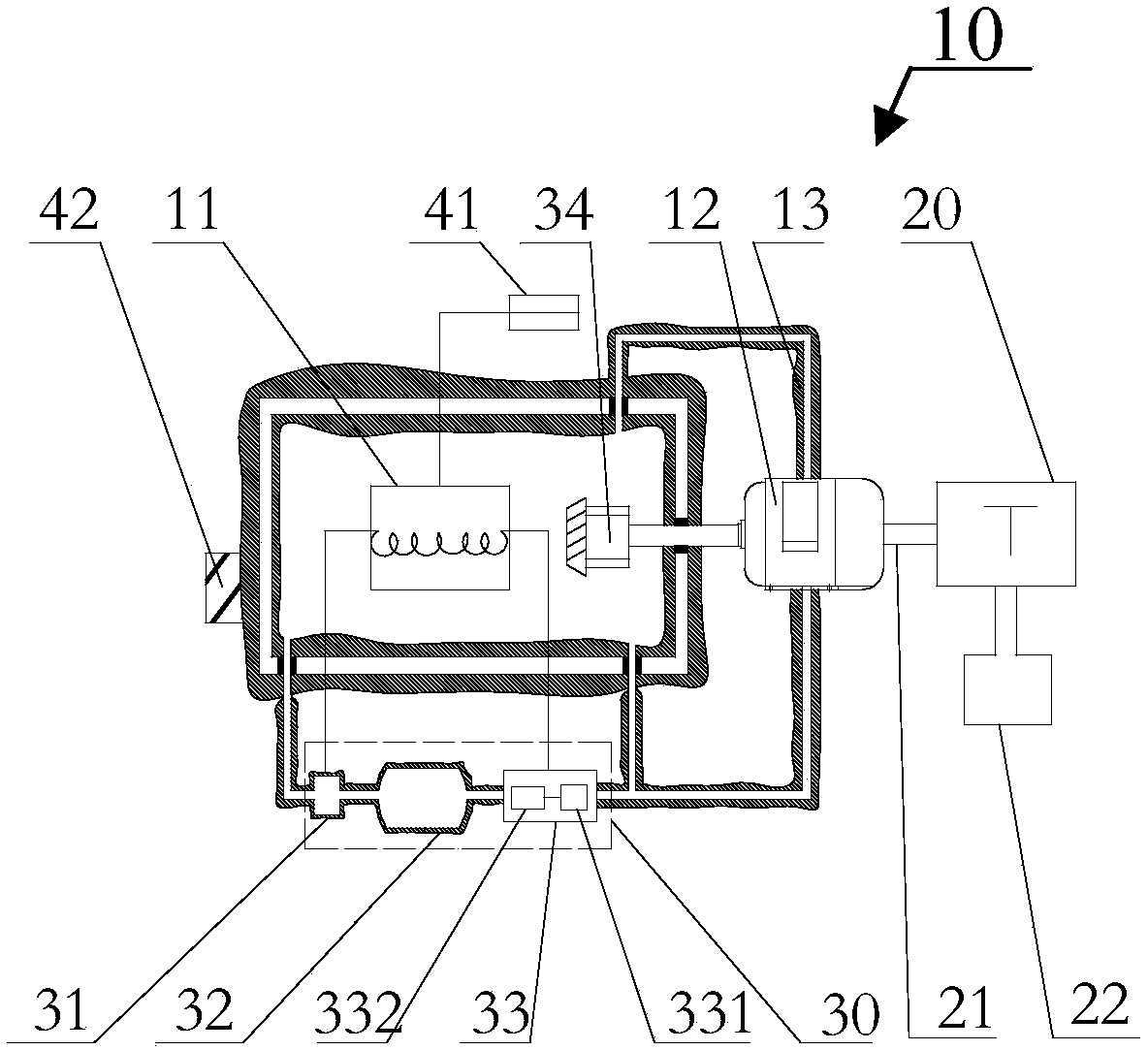

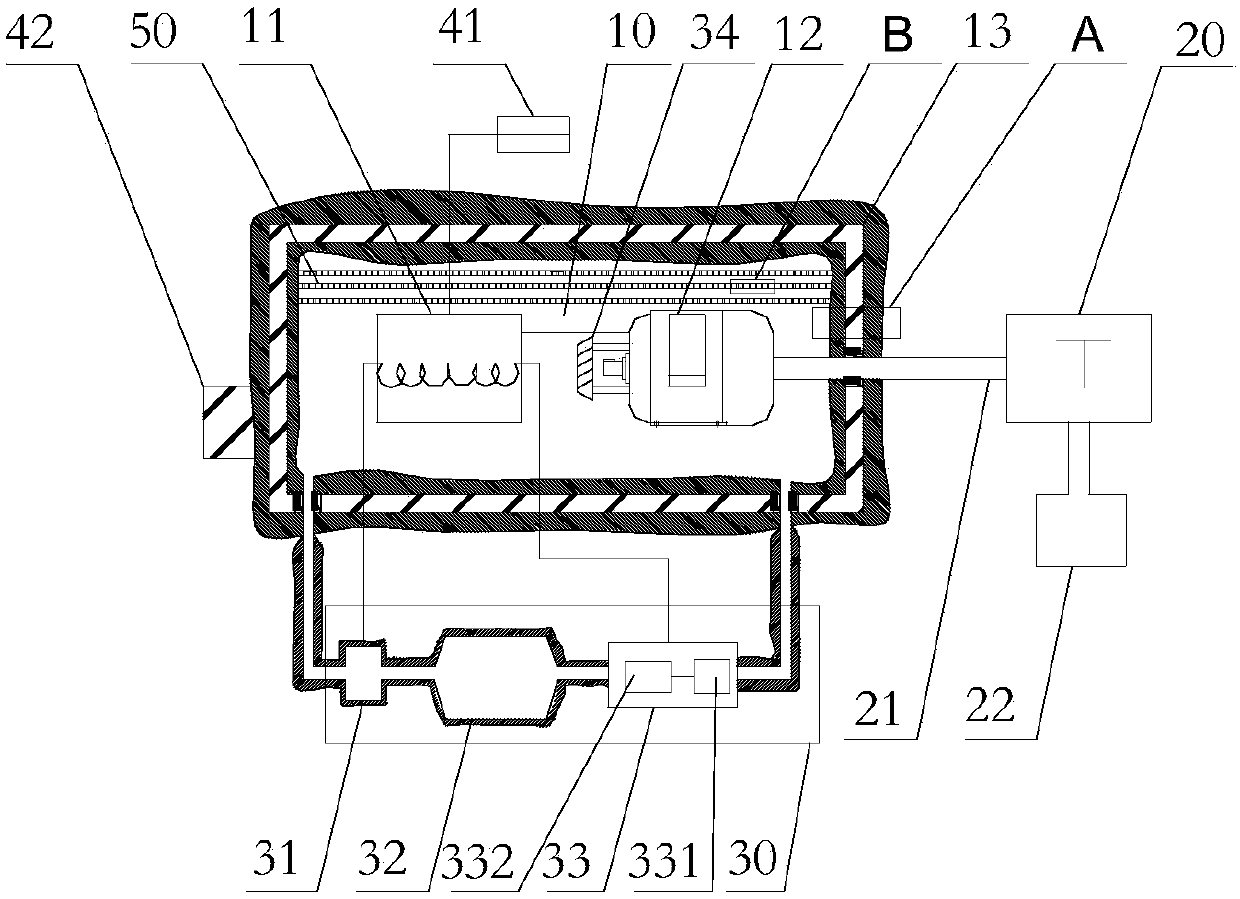

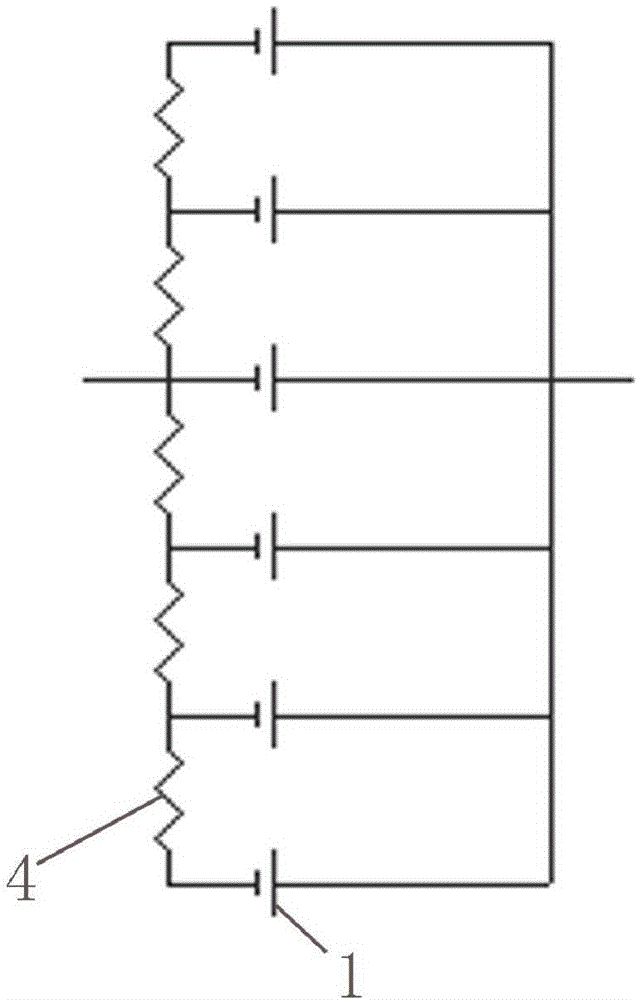

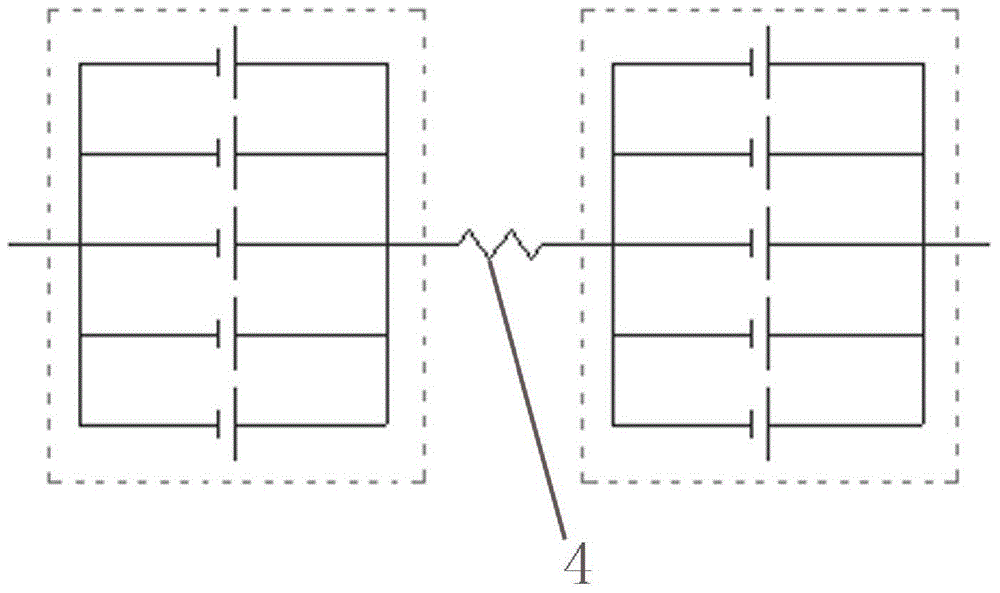

Superconducting power storage device and control method thereof

PendingCN107645212AEnergy storage density limitHigh energy storage densityElectrical storage systemDynamo-electric machinesSuperconducting CoilsCondensed matter physics

The invention provides a superconducting power storage device and a control method thereof. The superconducting power storage device comprises a first casing body, a superconducting coil and a superconducting generator. The superconducting part of the superconducting generator and the superconducting coil are arranged in the superconducting environment in the first casing body. The power output end of the superconducting generator is electrically connected with the superconducting coil. The superconducting coil and the superconducting part of the superconducting generator are arranged in the superconducting environment of the first casing body, so that both the superconducting generator and the superconducting coil are in a superconducting state. The power output end of the superconductinggenerator is electrically connected with the superconducting coil. The superconducting generator in the superconducting state is driven by a drive device to generate power, and the generated power isstored in the superconducting coil. The superconducting generator and the superconducting coil are in a superconducting state, so that the power storage density of the superconducting coil is not limited. The power storage efficiency of the superconducting power storage device is improved.

Owner:TECH XANADU OF RESONATORY SOLAR SYSTD CO LTD

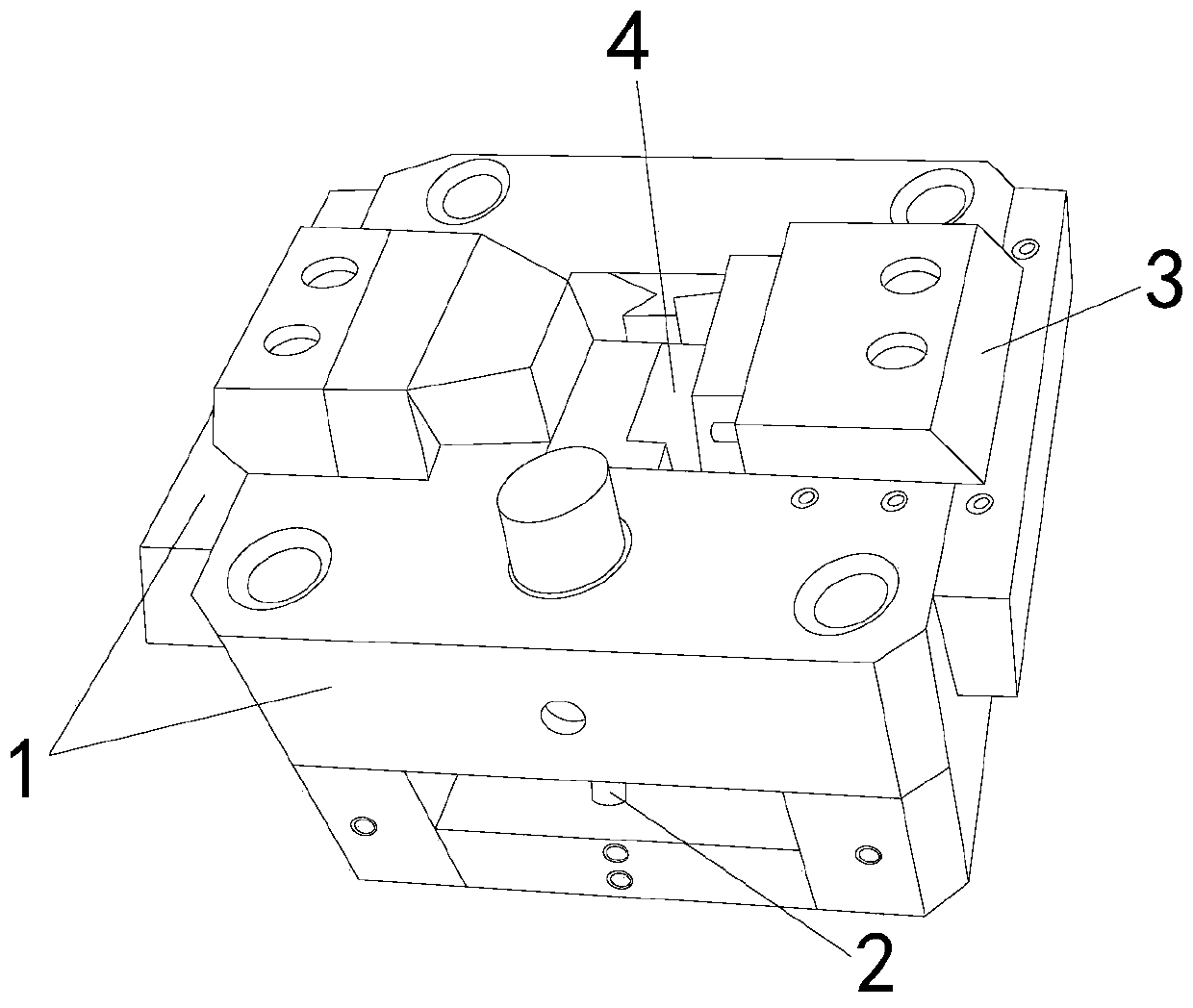

Stamping die for metal product casting

InactiveCN111421057AAddress structural strengthAddressing the Effects of Structural StrengthShaping toolsNon-rotating vibration suppressionResonanceEngineering

The invention discloses a stamping die for metal product casting. The stamping die structurally comprises an upper die base, an ejection male die, a male die plate and a spring plunger, wherein the ejection male die is arranged in the upper die base, the male die plate is correspondingly arranged at the top of the ejection male die, and the side edge of the male die plate is connected with the spring plunger. The stamping die has the beneficial effects that sound waves generated by vibration are dispersed through a part pressing device arranged in the stamping die, a stable transmission stateof the sound waves in air is broken, resonance cannot be formed, meanwhile, the sound waves are absorbed and prevented from being continuously transmitted outwards, and resonance caused by the fact that the sound waves are transmitted to a structure is prevented, so that the influence of high-frequency vibration on the structural strength is avoided.

Owner:宋红龙

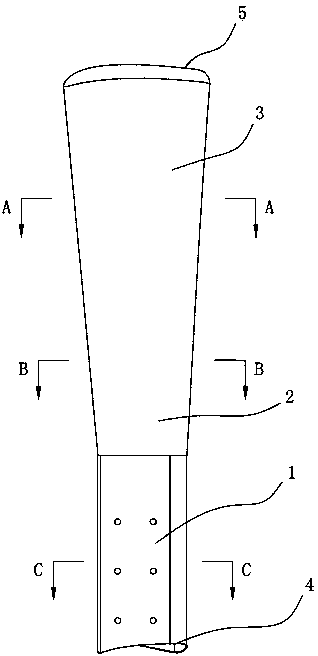

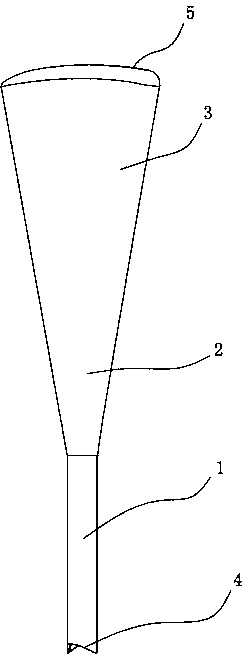

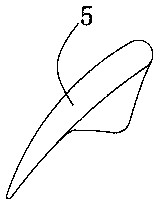

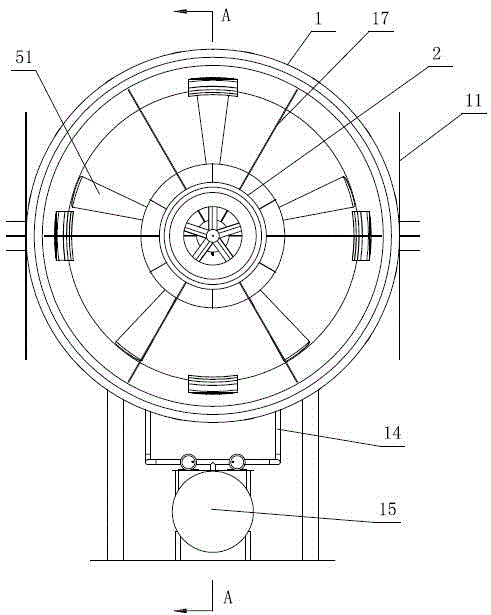

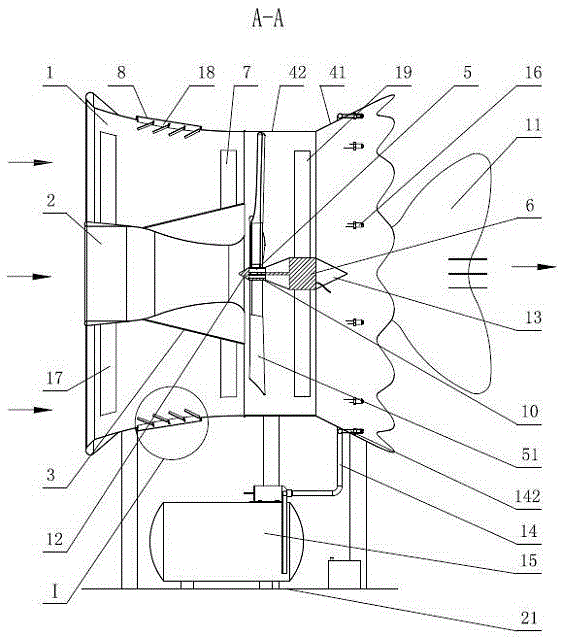

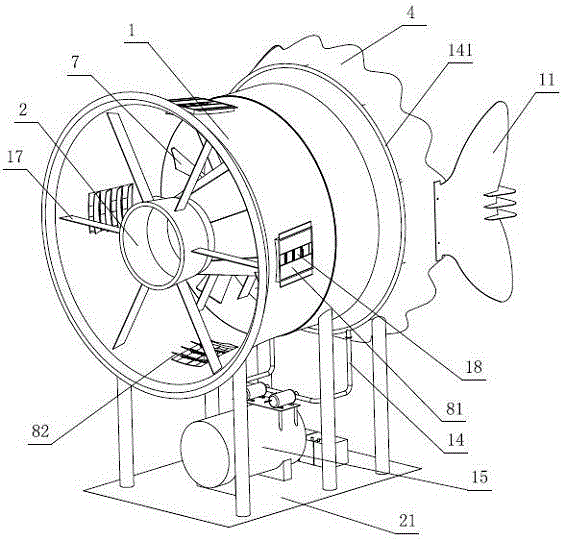

Blade for narrow pipe wind gathering type wind power generation device

ActiveCN103807112AIncrease wind areaIncrease conversion rateWind motor combinationsMachines/enginesFront edgeWind force

A blade for a narrow pipe wind gathering type wind power generation device comprises an installing section, a continuous working section and an outer working section, wherein the installing section extends towards the blade apex portion from the blade root portion in the blade spacing direction, the continuous working section is connected between the installing section and the outer working section in a smooth mode, the wing profiles of the three sections are round pointed asymmetric wing profiles, and the upper cambered surfaces and the lower cambered surfaces of the back edges of the wing profiles of the three sections are connected through smooth circular curves. The blade profile of the installing section is a twisted uniform-section blade profile, the blade profile of the continuous working section and the blade profile of the outer working section are twisted variable section blade profiles, the twisted directions of the three sections are the same, the back edges of the wing profiles are twisted towards the blade surface direction relative to the front edges of the wing profiles, and the twisted angle of the outer working section is larger than or equal to that of the continuous working section; the shape of the blade gradually becomes narrower from the blade apex portion to the transition connecting position between the installing section and the continuous working section, and the thickness of the sections of the blade gradually become larger from the front edges of the wing profiles to the back edges of the wing profiles. The blade conforms to the characteristics of fluid in a gradually shrinking type limited sealing body and meets the requirement for kinetic energy conversion.

Owner:无锡金蝎中蕴风电科技有限公司

A kind of stamping forming method of crankshaft speed signal disc

InactiveCN103769469BSimple manufacturing methodReduce processVehicle componentsHigh volume manufacturingPunching

The invention provides a stamping forming method of an automobile crankshaft signal panel. The stamping forming method comprises a blanking process, a groove rolling process, a punching process, a deep drawing and flanging process, a large and small signal hole punching process, a reshaping process and the like. By applying the stamping forming method for a crankshaft rotating speed signal panel, a complicated porous-structure panel body and a cover body part can be manufactured by virtue of a stamping forming process, and the method has the advantages of fewer processes, simple operation and control, high material utilization, short production period, less environmental pollution and the like, is beneficial to realization of automatic large-batch production and can be used for improving the production efficiency and lowering the production cost; signal hole processing is performed after metallic material plastic deformation, hole processing is more accurate, and the method can be used for solving the problems such as irregular shape of deep-drawn rectangular teeth, deformation of deep-drawn holes of a complicated-structure piece and high cracking, wrinkling and deformation possibility of a panel body due to uneven stress strain in a rectangular tooth primary stamping forming method, and can be applied to large-batch production of automobile parts.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

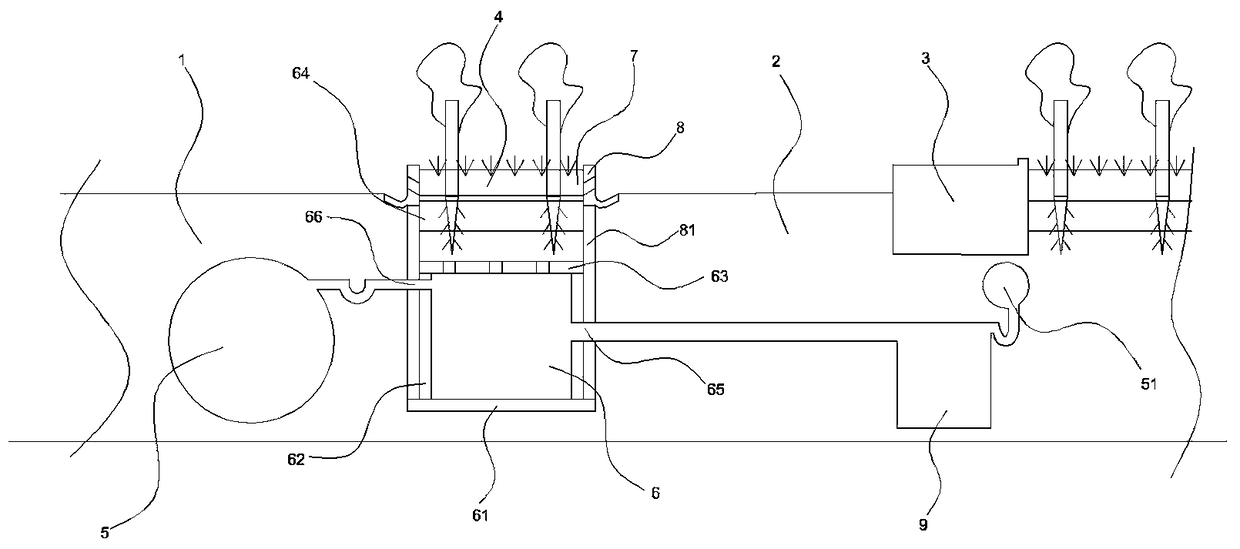

Urban road rainwater utilization technique

PendingCN108374473ASolve problems that require a centralized locationAddress structural strengthFatty/oily/floating substances removal devicesSewerage structuresEngineeringBottom water

The invention relates to an automatic rainwater collection and utilization technique, in particular to an urban road rainwater utilization technique, involving a vehicle road, a bicycle lane and a sidewalk. A green isolation belt is arranged between the vehicle road and the bicycle lane; a rainwater pipe is arranged below the vehicle road; a water supply pipe is arranged below the sidewalk. The urban road rainwater utilization technique is characterized in that a storage adjusting chamber is arranged below the green isolation belt; the storage adjusting chamber has a bottom water channel, support plates arranged on two sides of the bottom water channel, and a porous partition plate supported by the support plates on the two sides. It is intended herein that the storage adjusting chamber isarranged below the green isolation belt to allow municipal works to spray less water to green isolating belts in the roads during actual operation, the green isolation belts are kept moist throughoutthe year and are never frozen in winter, and the whole structure is simple.

Owner:安吉绿源生态科技有限公司

A capping device for a coke dry quenching tank car body

ActiveCN113736492BImprove stabilityReduce the amplitude of the side-to-side swingCoke quenchingCoke oven safety devicesCokeEngineering

The invention discloses a capping device for a coke dry quenching tank car body, which comprises a tank car, the upper surface of the tank car is movably connected with a feeding device, and the feeding device includes a stabilizing device, and the inner surface of the top of the stabilizing device is slidably connected There is a tank body, and the invention relates to the technical field of metallurgical equipment. The capping device of the dry quenching coke tank car body is equipped with an exhaust device. When the equipment is in use, the coke is sealed inside the tank body. The metal cover at the bottom of the cover plate is heated rapidly, and the air inside it expands when heated, and the hot air Entering the inside of the outer cover from the through hole, under the action of high-pressure airflow, the movable plate is pushed, the inserting plate protrudes from the inside of the outer cover, and the outer surface of the inserting plate is against the inner surface of the tank body, reducing the left and right swing of the cover plate. At the same time, it also increases the sealing effect of the equipment, which solves the problem of poor sealing effect of traditional CDQ tank cars.

Owner:ZHANGJIAGANG CHANGLI MACHINERY

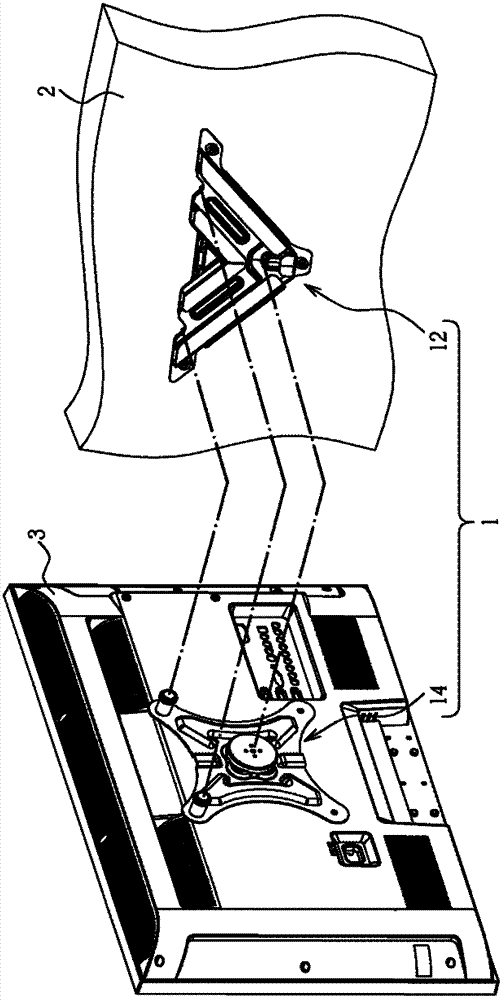

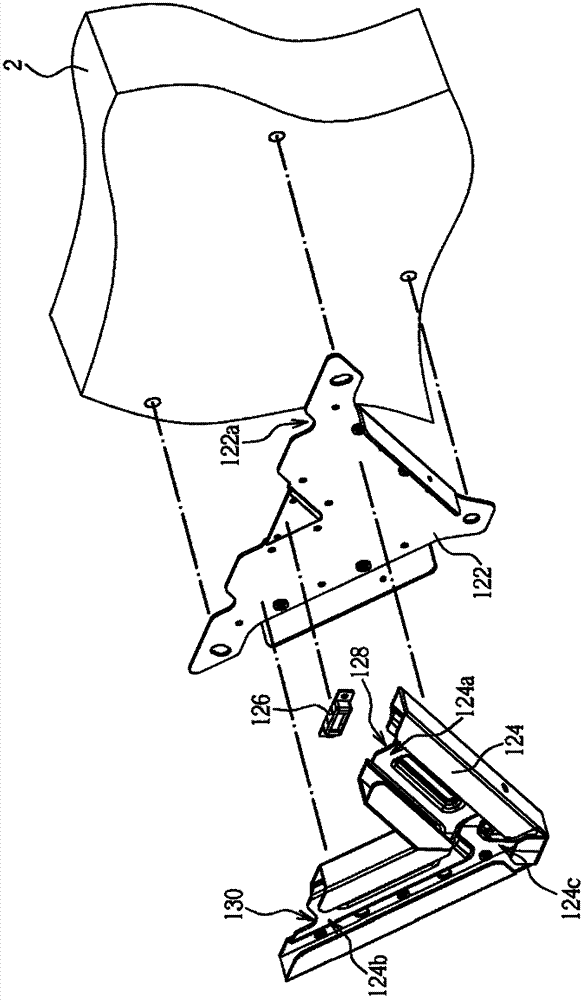

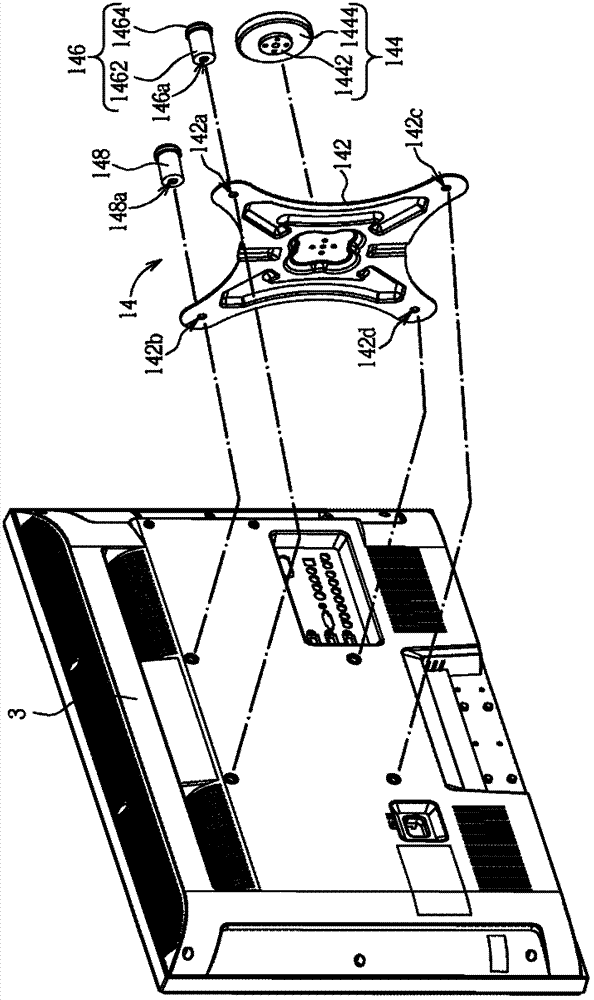

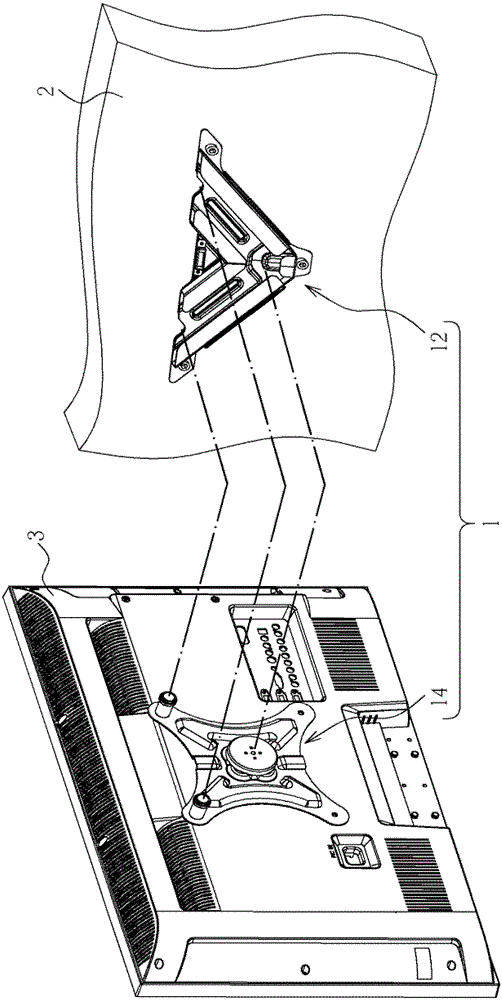

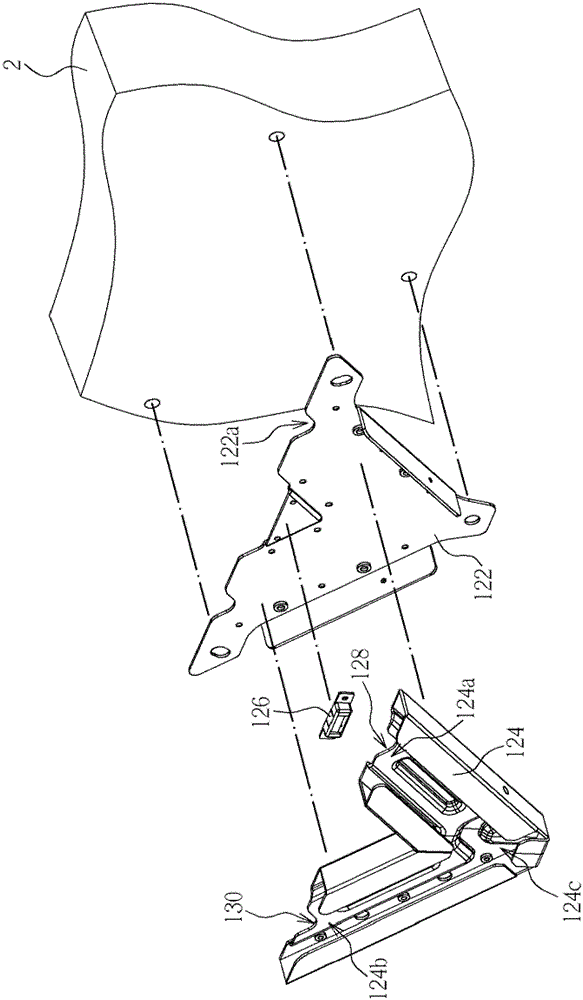

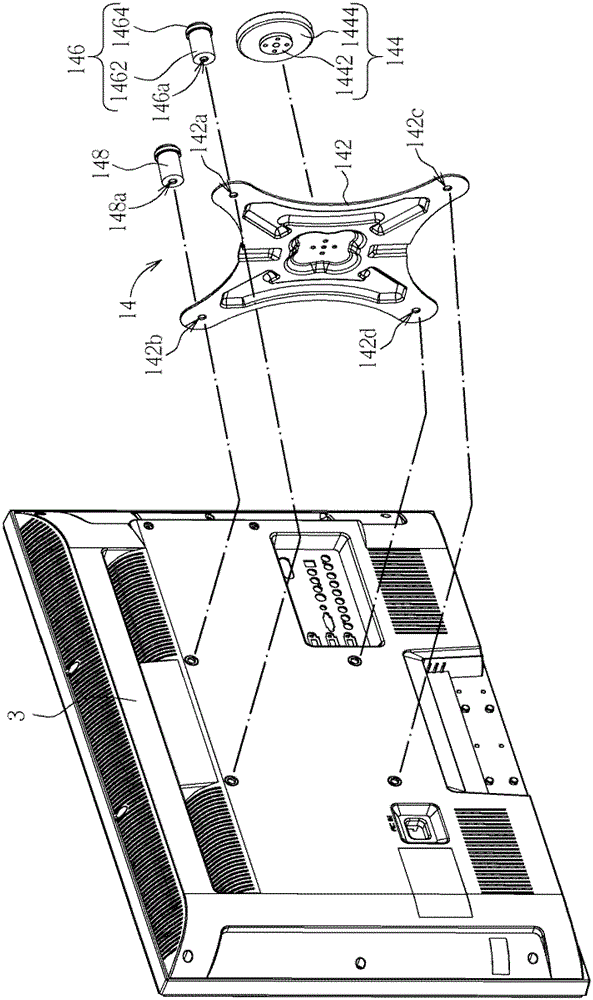

Wall-mounted combination

ActiveCN103363265AAddress structural strengthSolve operational problemsMachine supportsCasings/cabinets/drawers detailsEngineeringWall mount

Owner:AMTRAN TECH CO LTD

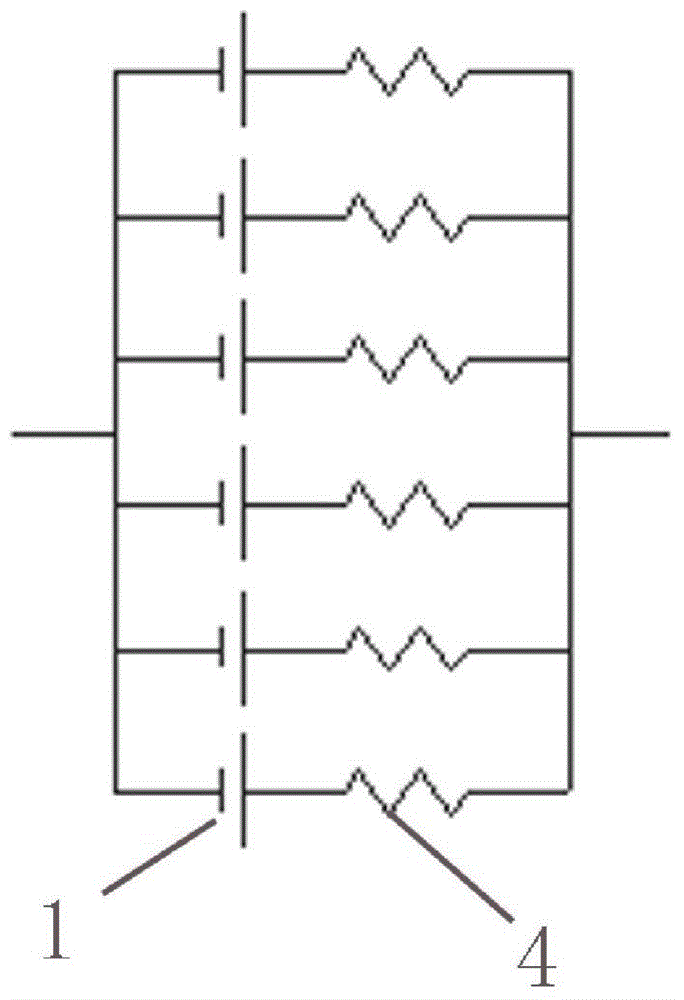

Novel safety structure for power battery module

InactiveCN106159354ASimple structureEasy to useCell component detailsSecondary cells servicing/maintenancePower batteryElectrical and Electronics engineering

The invention provides a novel safety structure for a power battery module. The safety structure comprises a protected circuit and bimetallic strips, wherein the bimetallic strips are connected in the protected circuit and serve as conducting elements; the bimetallic strips are provided with strength-weak parts. The safety structure is simple, convenient to apply and low in cost; in a scheme that the circuit is protected by fusing the conducting elements, the safety structure solves contradiction between the structural strength and the sensitivity of the conducting elements, and further solves the problem that the cost is too high due to use of fuses in a plurality of branch circuits.

Owner:BEIJING BOSTON POWER BATTERY

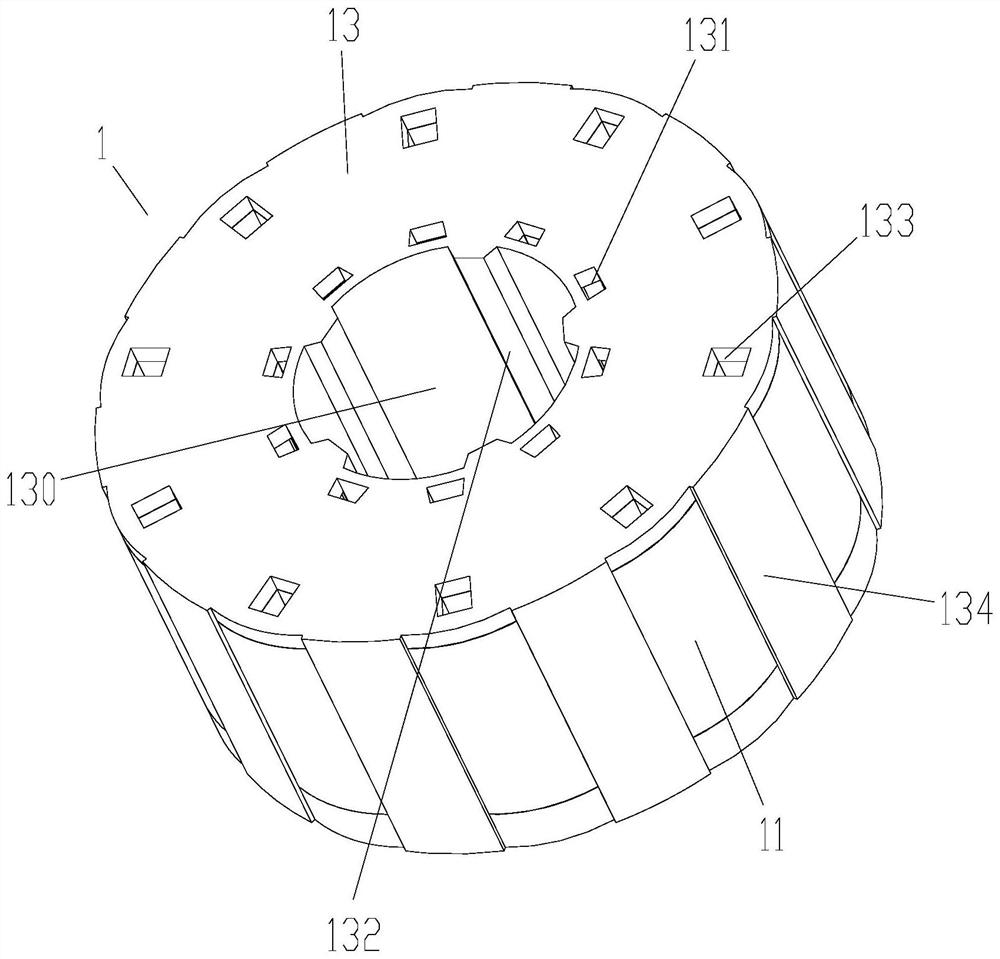

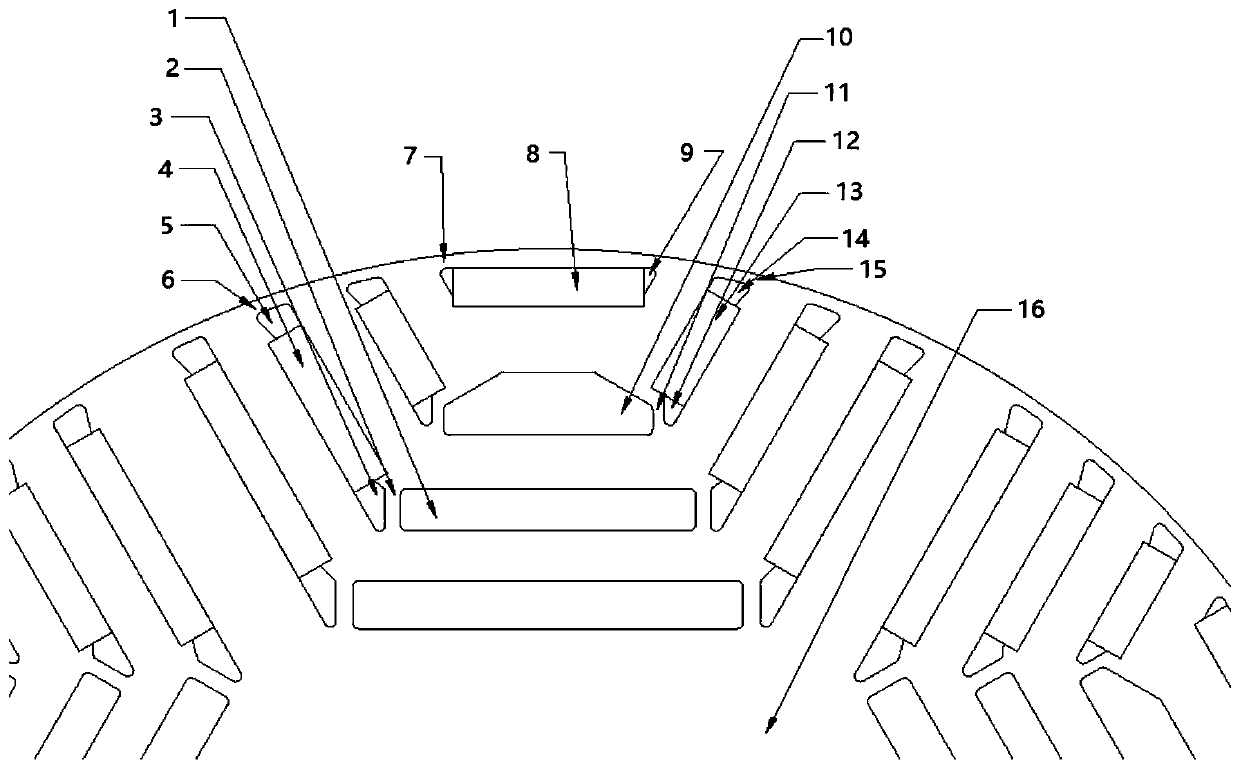

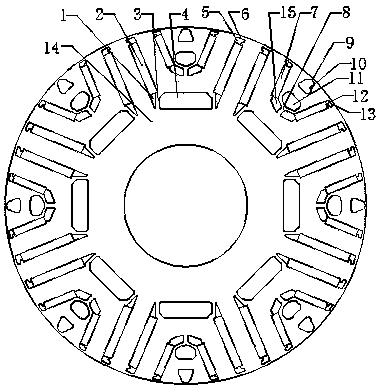

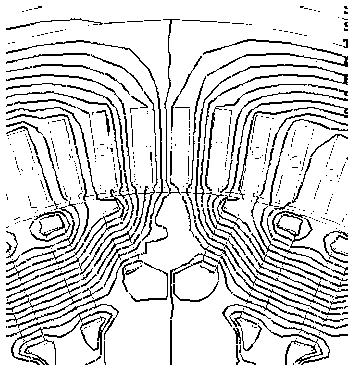

Permanent magnet synchronous motor rotor of mixed magnetic steel

PendingCN110855039AAddress structural strengthEnhanced magnetic concentration effectMagnetic circuit rotating partsPermanent magnet synchronous motorElectric machinery

The object of the present invention is to disclose a permanent magnet synchronous motor rotor of mixed magnetic steel, which is composed of first magnetic steel, second magnetic steel, third magneticsteel, and a rotor core. The first, second and third magnetic steel are alternately distributed and embedded in the rotor core to form a plurality of magnetic poles. Each magnetic pole has N layers ofmagnetic steel, wherein N is a natural number greater than or equal to 3. The first, second and third magnetic steel are alternately distributed on the magnetic poles in sequence. Compared with the prior art, the multilayer magnetic steel arrangement can easily obtain a good magnetic flux concentration effect and pole arc coefficient control, solves the contradiction between the structural strength and the magnetic isolation effect of the tangential magnetic steel arrangement, and effectively reduces the performance degradation caused by the pole leakage reactance of the motor. A layer of themultilayer magnetic steel close to the outer circle of the rotor core is the radial magnetic steel to further enhance the magnetic flux concentration effect to achieve the object of the present invention.

Owner:ZHEJIANG LOONGSON ELECTRIC DRIVE TECH CO LTD

wall hanging combination

ActiveCN103363265BAddress structural strengthSolve operational problemsMachine supportsCasings/cabinets/drawers detailsEngineeringWall mount

Owner:AMTRAN TECH CO LTD

Solar Components for Buildings

ActiveCN104333302BReduce the temperatureAlleviate hot spotsPhotovoltaic supportsPhotovoltaic energy generationBuilding integrationCollection system

The invention relates to a solar member for a building. The solar member comprises a photovoltaic assembly, a junction box, a connector, a frame, a filling material and a member backboard. A solar heat collector or a metal plate is employed as a photovoltaic assembly backboard, and a heating electronic device and the frame or the photovoltaic assembly backboard are contacted for heat dissipation; the photovoltaic assembly and the member backboard are installed in a fixation groove corresponding to the frame to form an enclosed space, and an integral member module is formed by bonding the filling material; the outer side surface of the frame is provided with a radiator and a heat conduction pipe for conducting solar energy to a solar heat collection system; and a refrigeration and heating apparatus is integrated on the photovoltaic assembly backboard and the member backboard, and an isolation layer is clamped between the photovoltaic assembly backboard and the member backboard. According to the invention, the solar member for the building can be used for photovoltaic generating and solar heat collection and temperature adjustment, can directly replace a decoration material, an insulation material, a waterproof material, an exterior-protected construction material and an air conditioning device on the roof or the wall of the building, and can also be integrally installed with the roof or the wall of an existing building so as to realize photovoltaic building integration.

Owner:ANHUI CHANGYUAN GREEN ENERGY

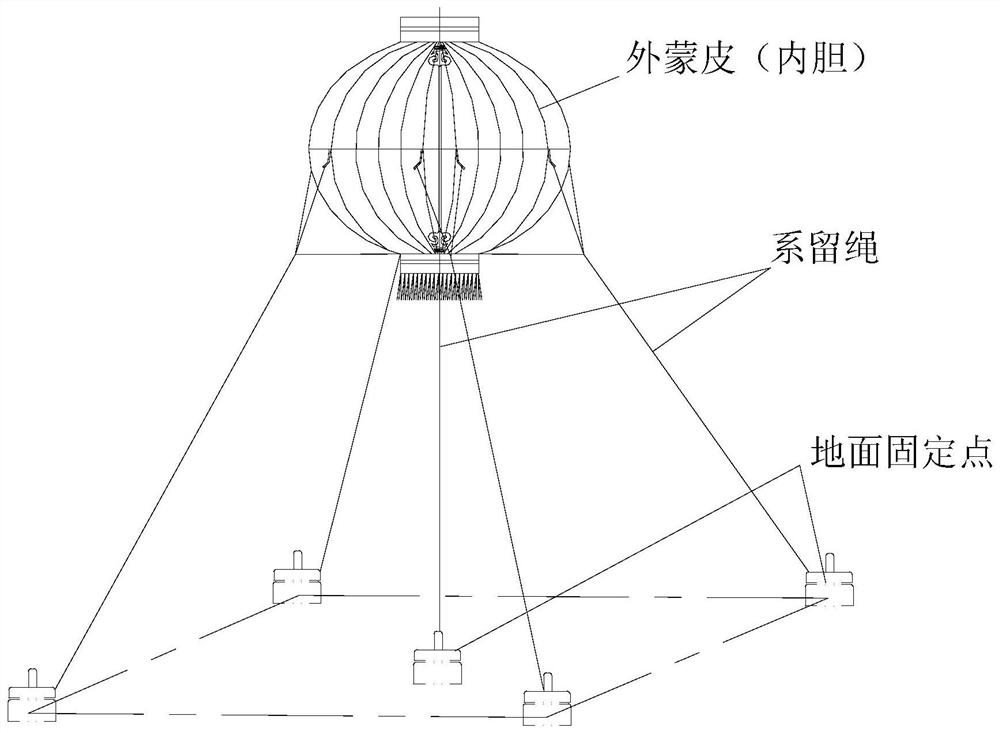

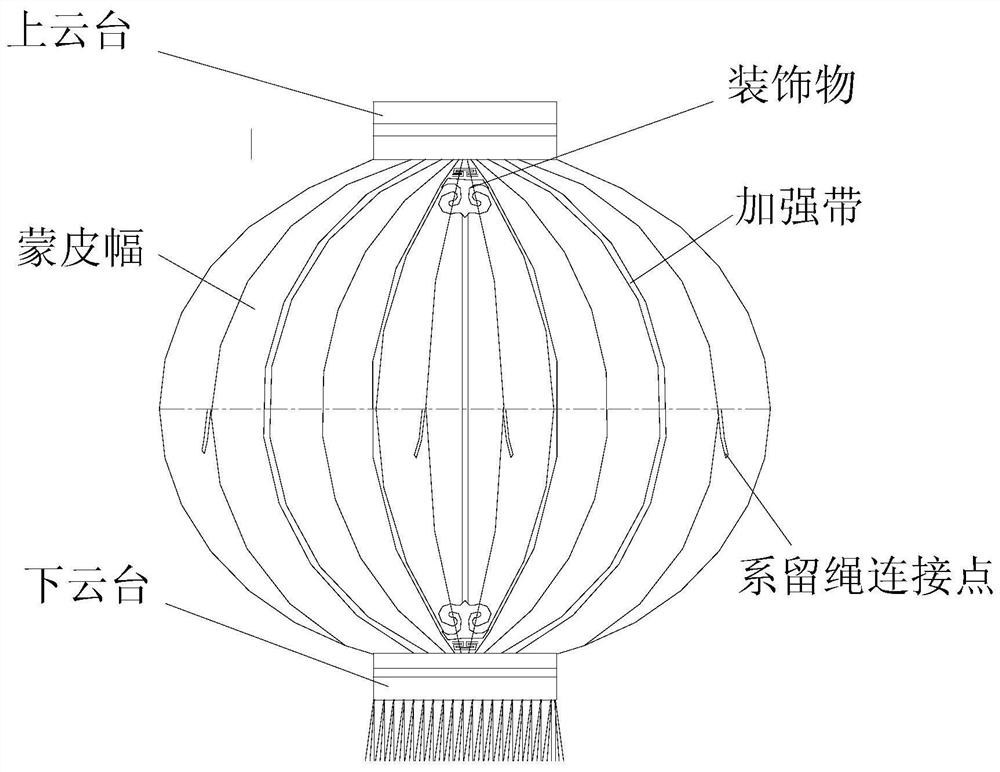

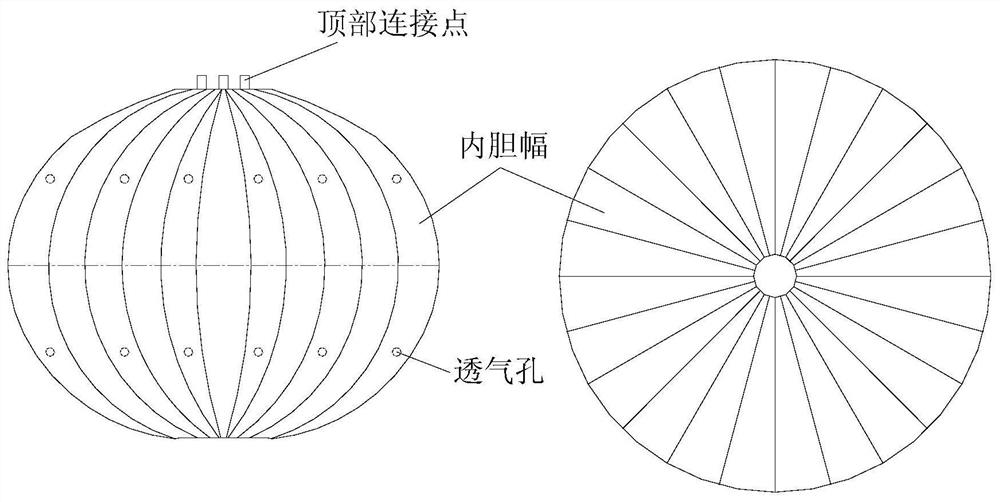

Foldable and unfoldable double-layer type large inflatable palace lantern and folding and inflating method

ActiveCN113181669AReliable structural airtightnessThe decorative effect is beautiful and generousStage arrangementsStructural engineeringLantern

The invention relates to a foldable and unfoldable double-layer type large inflatable palace lantern and a folding and inflating method. The inflatable palace lantern comprises an outer skin used for bearing the force and an inner container, wherein the inner container is of a multi-layer structure, an outer layer of the inner container is a nylon composite film, and an inner layer of the inner container is at least two layers of PE composite films; air holes for extruding residual gas are uniformly distributed in the nylon composite film; the inner container is fixedly connected to the inner side of the outer skin, an upper part and the bottom of the outer side of the outer skin are connected through a holder to form a palace lantern; a palace lantern is connected with a ground mooring point through the mooring rope, and the mooring rope is used for resisting the wind and fixing the palace lantern.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Straight-through narrow tube wind power generation system

ActiveCN103807102BExpand application wind speed lower limitSmooth dischargeWind motor combinationsRenewable energy generationImpellerWind power system

The invention discloses a straight-through type narrow-pipe wind collecting wind power generation system which comprises an outer narrow pipe. An inner narrow pipe is overall sleeved with the outer narrow pipe, a conical sleeve is fixedly connected to the peripheral face of the inner narrow pipe, the wide head end of the conical sleeve is located at the tail of the outer narrow pipe, guide vanes are arranged on the conical sleeve, the inner narrow pipe and the conical sleeve are fixedly supported in the outer narrow pipe, an air outlet of the inner narrow pipe is an external expansion opening, a wake flow pipe is axially and fixedly connected to the air outlet end of the outer narrow pipe, an impeller and a power generator are installed in the wake flow pipe, the impeller is close to the tail of the outer narrow pipe, blades on the impeller rotate under the driving effect of wind power to drive the power generator to generate power, and an external expansion section is arranged on the wake flow pipe. According to the straight-through type narrow-pipe wind collecting wind power generation system, on the basis that the inner-pipe wind speed is effectively quickened, the wind power use rate can be further improved, and the efficiency of the power generator can be further improved; meanwhile, due to the arrangement of a fogging machine, fogging is achieved through self-supplying of green electric energy, haze and dust are finally reduced through fogging, the atmospheric environment is improved, and therefore application of the wind power generation system is expanded.

Owner:无锡金蝎中蕴风电科技有限公司

A rail vehicle and its undercarriage structure

The invention discloses a railway vehicle and an underframe structure thereof. The chassis structure comprises underframe edge beams, a floor, an end beam, a first sleeper beam, and a second sleeper beam, wherein the underframe edge beams are parallelly and oppositely arranged, and the end beam are arranged at one end of the structure. The upper portion of the middle part of the underframe edge beams is provided with a middle door hole, and the lower portion of the middle part of the underframe edge beams is provided with a mounting cavity, wherein the mounting cavity is used for mounting mobile pedals. A stair reinforcing device comprises cross beams, a short longitudinal beam and a long longitudinal beam, wherein the cross beams are arranged on the two sides of the middle door hole and used for connecting the two oppositely-arranged underframe edge beams, and the upper portions of the cross beams are in plug-in connection with the floor. The short longitudinal beam is connected to the cross beams at two sides, the long longitudinal beam is connected with the first sleeper beam and the cross beam corresponding to one side of the first sleeper beam, and the distance from the firstsleeper beam to the cross beam corresponding to one side of the first sleeper beam is not greater than that from the second sleeper beam to the cross beam corresponding to one side of the second sleeper beam. According to the railway vehicle and the underframe structure thereof, due to the force transfer between the long longitudinal beam, the cross beams and the short longitudinal beam, the bearing capacity, especially anti-longitudinal impact capacity, of underframe edge beams at the portion of the middle door hole is improved, thus meeting collision requirements when accidental collision occurs between vehicles; in addition, the problem of insufficient strength and rigidity in a middle-arranged vehicle door and a stair rear underframe structure can be solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

A kind of preparation method of carbon-based reinforcement/resin composite material

ActiveCN111592737BEvenly dispersedSolve the problem of loss of mechanical propertiesPtru catalystModified carbon

The invention discloses a microwave-assisted efficient construction method for a high-strength interface of a carbon-based reinforcement / resin composite material, and belongs to the field of compositematerials. The method comprises the following step: modifying a carbon-based reinforcement by nanoparticles through a synergistic effect of physical coating and chemical grafting so as to form an interface (a cage-shaped interface structure) coated with a cage-shaped structure carbon source material shell. Based on the microwave irradiation activation principle, the activation of the carbon-basedreinforcement and the uniform self-assembly of the nanoparticles are realized by adjusting the ratio of the transition metal catalyst to the carbon source material to the nanoparticles. Compared withcomposite material traditional interface enhancement, the method of the invention is more efficient and faster, realizes the nanometer reinforcement of the interface of the carbon-based reinforcement / resin composite material, solves the problem that the structural integrity and strength of the carbon-based reinforcement are damaged by discharging and sparking of the carbon-based reinforcement ina microwave field, and has important significance in preparing the high-performance carbon-based reinforcement / resin composite material; and the high-strength interface can be applied to the high-techfields of composite material pressure containers, aerospace crafts and the like.

Owner:BEIJING UNIV OF CHEM TECH

Layout structure of liquefied natural gas fuel tanks in bulk carriers

ActiveCN110789663BSolve the problem of insufficient support strengthAddress structural strengthHull interior subdivisionFor bulk goodsBulk cargoFuel tank

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

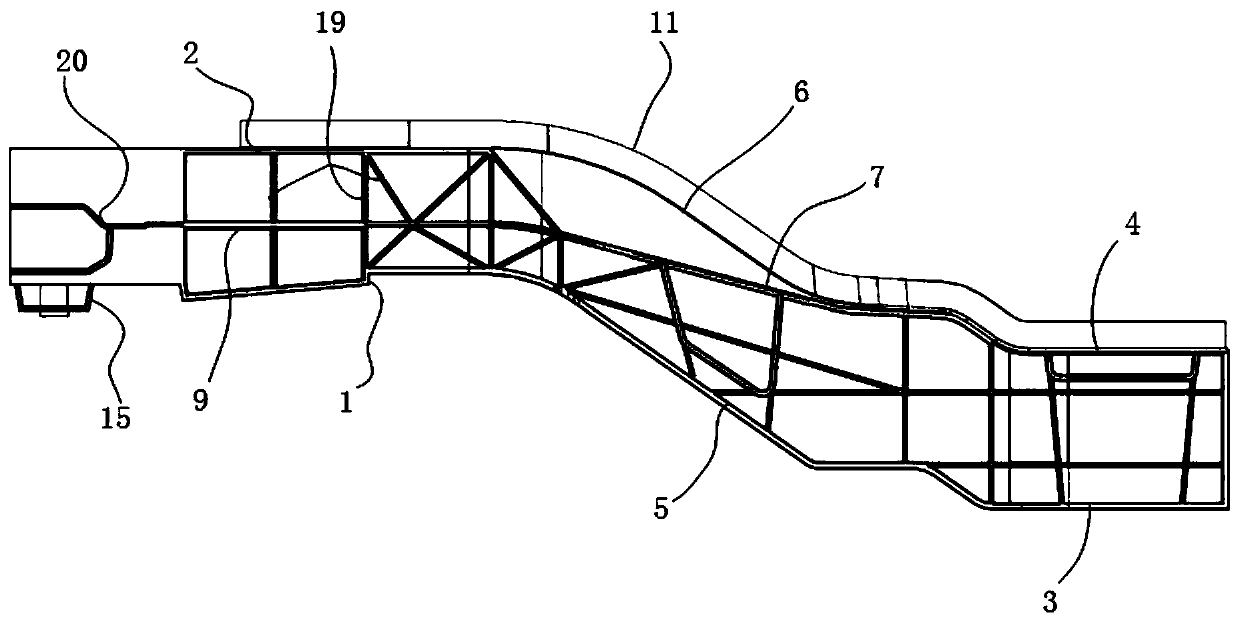

Land leveler and rear rack connecting structure of land leveler

InactiveCN112095707AImprove reliabilityImproved fatigue reliabilityMechanical machines/dredgersCivil engineeringLightening holes

The invention discloses a land leveler and a rear rack connecting structure of the land leveler. The rear rack connecting structure of the land leveler comprises a first upper hinge connecting plate,a second upper hinge connecting plate, a lower hinge connecting plate, a left side supporting plate and a right side supporting plate; the left side supporting plate and the right side supporting plate are arranged in the vertical direction and are parallel; the first upper hinge connecting plate, the second upper hinge connecting plate and the lower hinge connecting plate are sequentially arranged in the horizontal direction from top to bottom; the two ends of the first upper hinge connecting plate, the second upper hinge connecting plate and the lower hinge connecting plate are connected with the left side supporting plate and the right side supporting plate correspondingly to form a box type structure; hinge pin holes are formed in the corresponding positions of the first upper hinge connecting plate, the second upper hinge connecting plate and the lower hinge connecting plate; lightening holes are formed in the first upper hinge connecting plate, the second upper hinge connecting plate and the lower hinge connecting plate correspondingly; and hinge lugs are further connected to the inner sides of the left side supporting plate and the right side supporting plate between the second upper hinge connecting plate and the second lower hinge connecting plate, and the hinge lugs are drop-shaped.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD +1

Car and its rear torque box

ActiveCN109808773BEffective protectionAddress structural strengthUnderstructuresSuperstructure subunitsStructural engineeringMechanical engineering

The invention discloses an automobile and a rear torsion box thereof. The automobile rear torsion box comprises a first connecting part, a second connecting part and a third connecting part, wherein the first connecting part comprises a first base plate and a second base plate which are oppositely arranged, and a first lining plate which is fixed between the first base plate and the second base plate through a plurality of first reinforcing ribs; the second connecting part comprises a first buffer plate, a second buffer plate, a third buffer plate and a first support plate; the third connecting part comprises a third base plate and a fourth base plate which are oppositely arranged; wherein, both ends of the first buffer plate are respectively connected with the first base plate and the third base plate; the first support plate is arranged on the first buffer plate, and an angle formed between the first support plate and the first buffer plate is greater than 0 degree and smaller than 180 degrees; and both ends of the first support plates are respectively connected to the first connecting part and the second connecting part. By adopting the rear torsion box, the problems that a conventional metal plate rear torsion box is low in integration degree, complex in process and high in cost, and the structure of the rear torsion box is deformed easily because of collision of the rear part of the automobile are solved, and a battery pack can be effectively protected.

Owner:AIWAYS AUTOMOBILE CO LTD

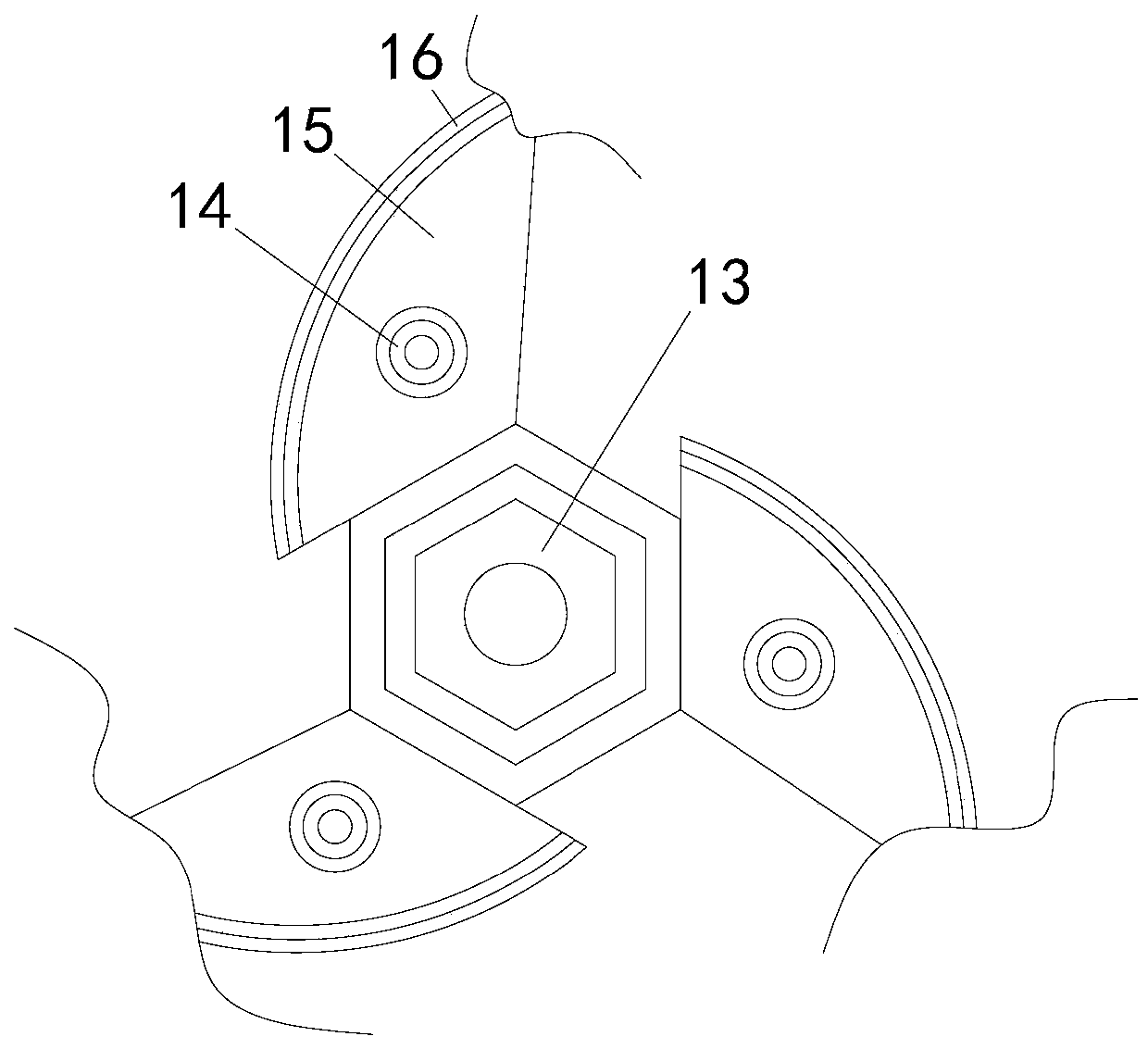

Permanent magnet synchronous motor rotor with high-performance tangential magnetic circuit structure

PendingCN110138119AAddress structural strengthAvoid performance degradationMagnetic circuit rotating partsPermanent magnet synchronous motorMagnetic poles

The invention aims to disclose a permanent magnet synchronous motor rotor with a high-performance tangential magnetic circuit structure. The rotor comprises a rotor core, first magnetic steels and second magnetic steels, the first magnetic steels and second magnetic steels are respectively inlaid into the rotor core, each magnetic pole of the rotor is formed by two first magnetic steels and two second magnetic steels which are uniformly distributed at the two sides of the central line of the magnetic pole, and a first magnetic pole is located at the outer side of a second magnetic pole. Compared to the prior art, the contradiction between the structural strength and the magnetic isolation effect of the tangential magnetic steel arrangement is solved, the multilayer magnetic steel arrangement is adopted to easily obtain the better magnetic gathering design and pole arc coefficient control, effectively inhibit the performance reduction caused by the leakage reactance of the motor pole and achieve the purposes of the invention.

Owner:ZHEJIANG LOONGSON ELECTRIC DRIVE TECH CO LTD

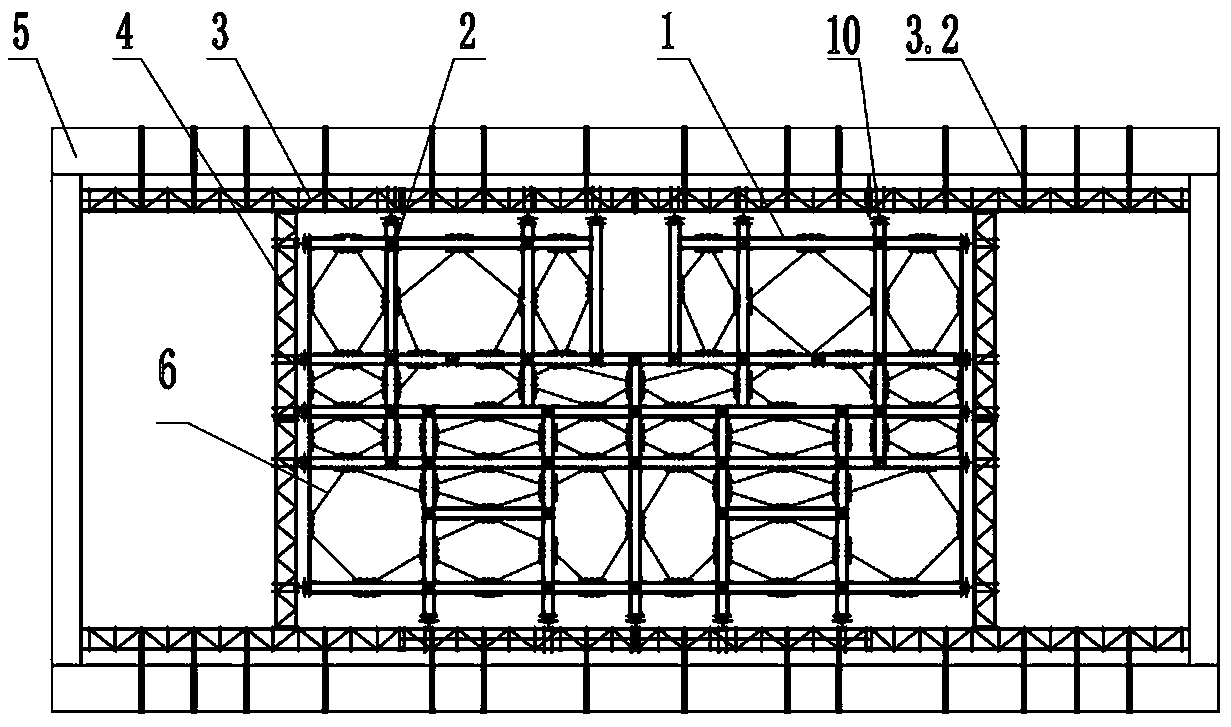

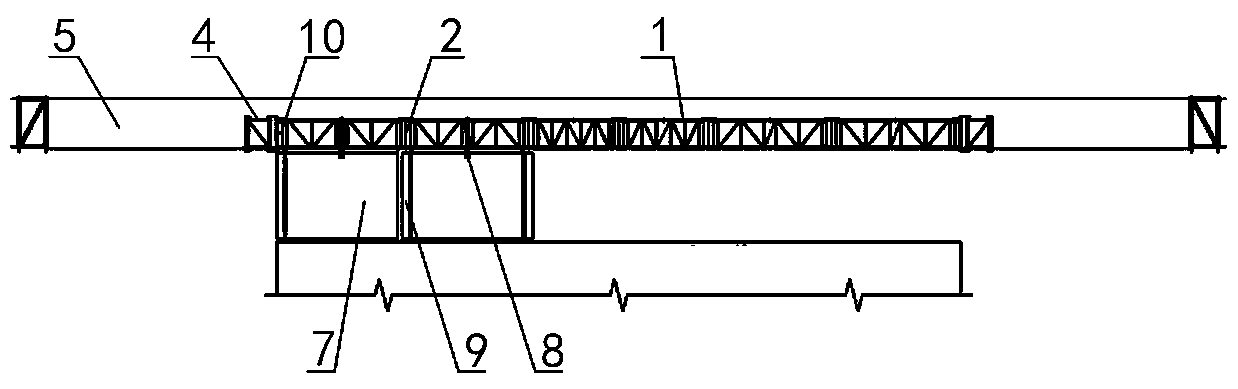

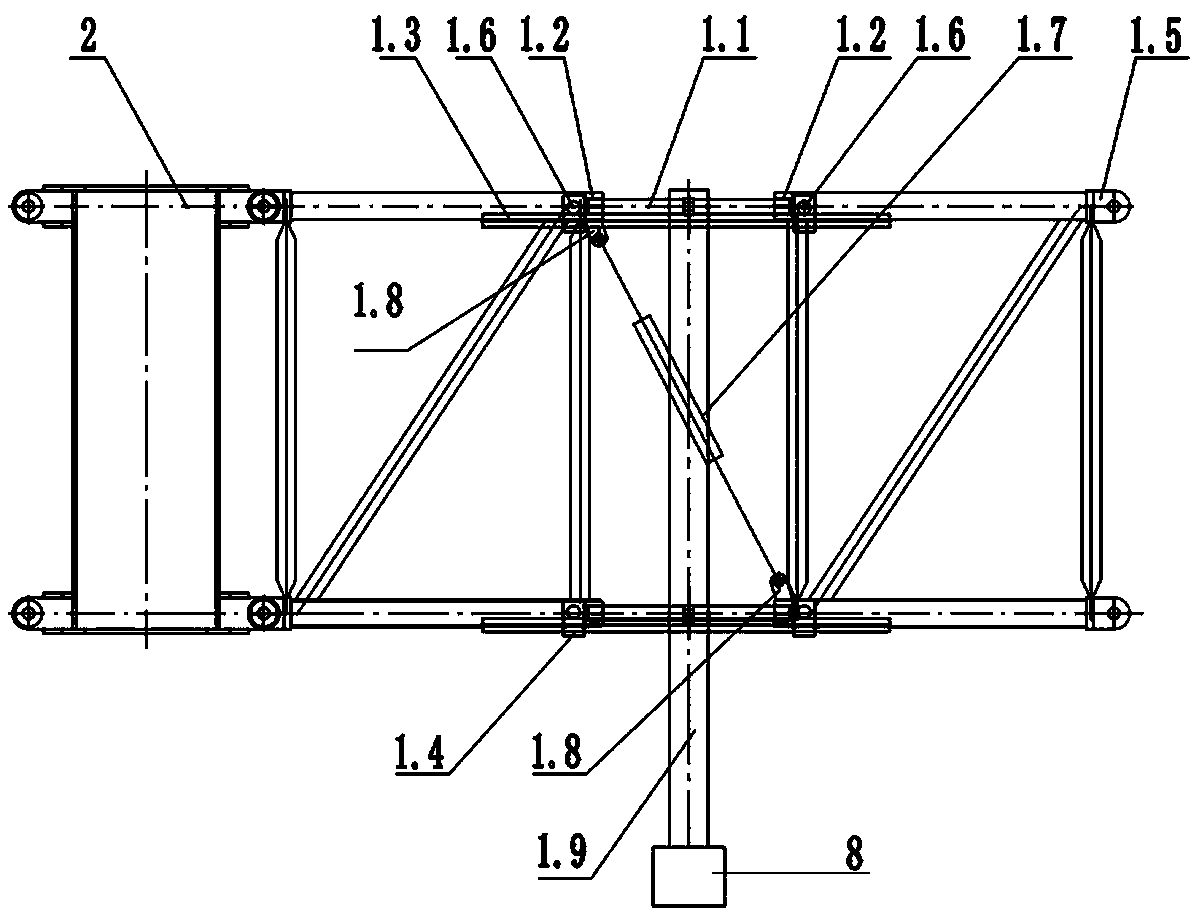

Prefabricated wall panel temporary positioning support system and construction method based on construction platform

ActiveCN108894513BAddress structural strengthEasy to combineBuilding material handlingSupporting systemArchitectural engineering

The invention relates to a temporary positioning support system for prefabricated wallboard based on a construction platform and a construction method thereof. The temporary positioning support systemfor prefabricated wallboard based on a construction platform includes a support piece at the top of the wallboard to be mounted, a node connector above an inner cast-in-place column, an external wallconnector above a cast-in-place concrete column and an auxiliary beam adjacent to the peripheral structure and the like. The support piece is connected to the node connector to form a net frame structure, which is connected with the auxiliary beam through the external wall connecter, and the auxiliary beam is connected with a platform. The node connector and the support piece form an inner wall hanging passageway, and the external wall connector, the support piece and the auxiliary beam form an outer wall hanging passageway. The screw connection between the support pieces is convenient to realize the combination of different size support pieces by modularization; the stiffness of the control structure is controlled by adding inclined tie rod and horizontal joint steel pipe between supportpieces and multi-position connection among the main and auxiliary beam and the platform. The positioning support system adapts to the layout of different building structure or the installation dimension of special member, and realizes the automatic temporary positioning of prefabricated wallboard.

Owner:CABR CONSTR MACHINERY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com