Five-axis linkage 3 D printer mechanism

A 3D printer, five-axis linkage technology, applied in the direction of additive processing, etc., can solve the problems of inability to meet the needs of multi-field applications, low work efficiency, easy collapse of suspended structures, etc., to achieve easy heat dissipation, improve printing technology, and improve stability and stiffness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

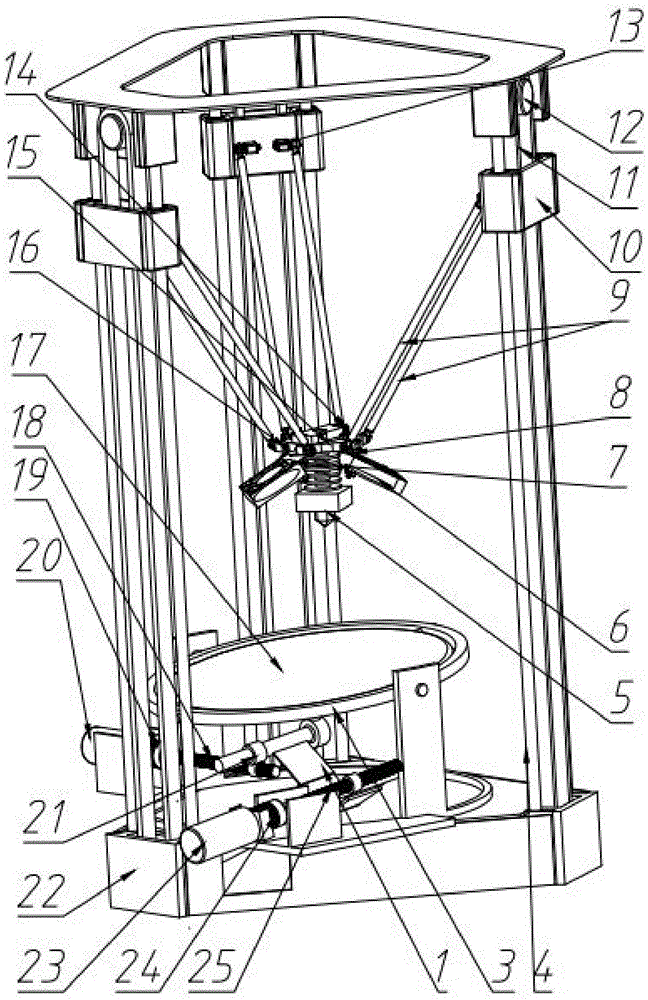

[0024] The invention is mainly composed of a body system, a control system, a printing system and a display system.

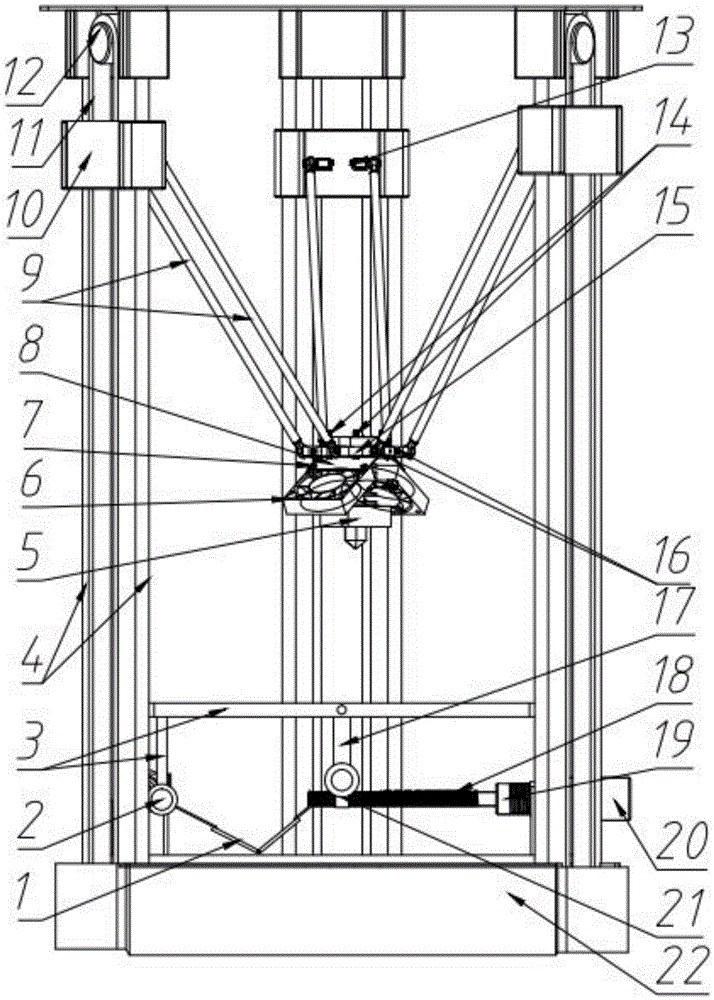

[0025] Such as figure 2 Shown, (22) frame supports all parts, is a hollow equilateral triangular prism, (4) supporting rod two groups, three edge places respectively arrange a group, are used to form (10) slide block and do up and down Reciprocating linear guide rail; at the same time, one (12) synchronous pulleys are arranged on the upper and lower sides of the three edges, and the power is provided by the motor below. (10) slide block is matched with (4) support bar by slide bearing, blocks one side of (11) synchronous belt by internal concave-convex structure, realizes (11) synchronous belt transmission,.

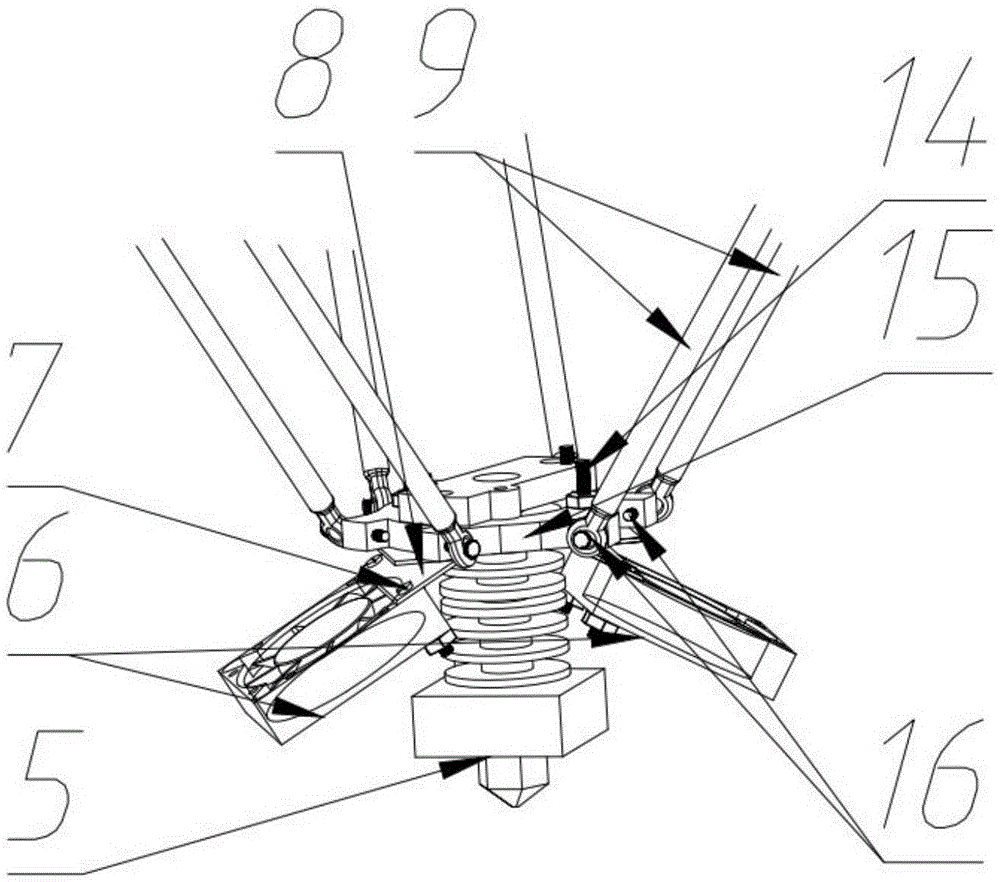

[0026] Such as image 3 As shown, (15) upper moving platform and (10) sliding block are respectively connected to the two ends of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com