Solar member for building

A technology for solar energy and construction, applied in sustainable buildings, electrical components, renewable energy integration, etc., can solve problems such as affecting the reliability and life of material bonding, high thermal resistance of photovoltaic module backplanes, and inability to effectively absorb thermal energy. , to achieve the effect of good safety protection performance, stable and reliable insulation performance, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

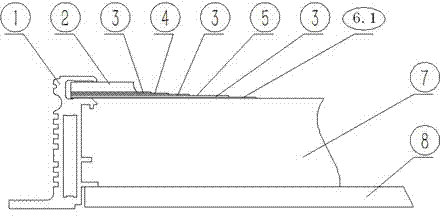

[0055] see figure 1 , 3 and Figure 8-11 , the present invention includes a photovoltaic module, a negative connector 24, a positive connector 25, a junction box 11 and a frame 1, and the photovoltaic module is composed of a glass panel 2, a solar cell 4, an adhesive 3, an insulating film 5, and a metal plate 6.1 (metal The plate is used as the back plate of the photovoltaic module); the contact surface of the metal plate 6.1 and the solar cell 4 is treated with an insulating layer or the insulating film 5 is bonded; the glass panel 2, the solar cell 4, the insulating film 5 and the metal plate 6.1 are formed by bonding the adhesive 3 It is a whole and encapsulated in the frame 1; the metal plate 6.1 is in close contact with the frame 1. The heating device in the junction box 11, or the heating device 12 is installed on the printed circuit board 52, and is fixed on the frame 1 (or on the metal plate 6.1); the positive L-shaped connector 25 and the negative L-shaped connecti...

Embodiment 2

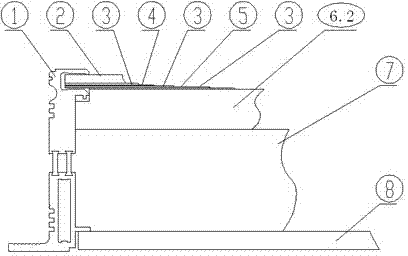

[0059] see figure 2 , 3 and Figure 8-11 , the present invention includes a photovoltaic module, a negative connector 24, a positive connector 25, a junction box 11 and a frame 1, and the photovoltaic module is composed of a glass panel 2, a solar cell 4, an adhesive 3, an insulating film 5, and a solar collector 6.2 (The solar collector is used as the backboard of the photovoltaic module); the contact surface of the solar collector 6.2 and the solar cell 4 is treated with an insulating layer or bonded with an insulating film 5; the glass panel 2, the solar cell 4, the insulating film 5 and the solar heat collector The device 6.2 is formed as a whole by bonding with the adhesive 3 and encapsulated in the frame 1; the solar heat collector 6.2 is in close contact with the frame 1. The heating device in the junction box 11, or the heating device 12 is installed on the printed circuit board 52, and is fixed on the frame 1 (or on the solar collector 6.2); the positive L-shaped c...

Embodiment 3

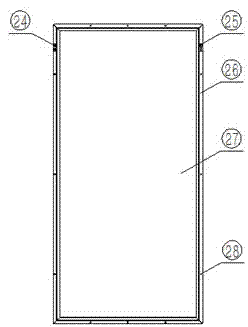

[0066] see Figure 12 , 13 In the present invention, the structural design of the frame of the traditional photovoltaic module is changed to meet the structural requirements of the building envelope and the functional requirements of the photovoltaic module. On the inner side of the frame, the photovoltaic module installation groove and the positioning boss of the component back plate are designed. Two vertical bosses are designed on the inner side of the frame, namely the junction box limiting boss 15 and the junction box anti-slip boss 16, which cooperate with the corresponding grooves of the junction box shell to fix the junction box. A plurality of grooves are designed on the outside of the frame, that is, the frame structure groove 21, to increase the structural strength and increase the contact surface between the sealant and the frame surface when filling the sealant. The arc-shaped groove on the outside of the frame, the sealing strip installation groove 20 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com