Blade for narrow pipe wind gathering type wind power generation device

A technology for wind power generation devices and blades, which is applied to wind power generator components, wind power generation, wind power engines, etc. It can solve problems such as unknown and no specific instructions, and achieve penetration, increase wind energy conversion rate, and improve start-up performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

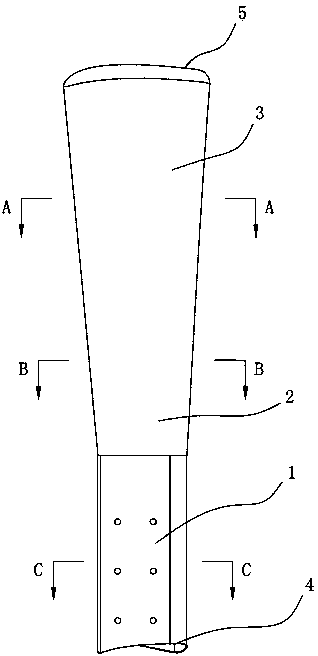

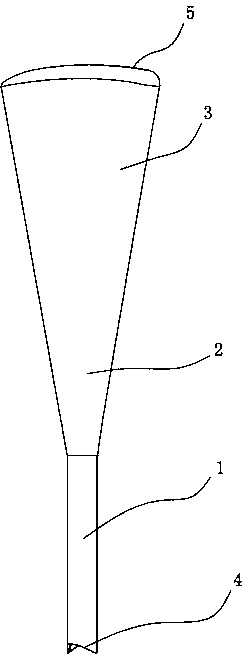

[0027] The concepts used in this application are well known in the art, and related concepts are described below:

[0028] Blade root: the end of the blade connected to the hub;

[0029] Tip: The opposite end of the blade to the root, that is, the outermost segment of the blade.

[0030] Blade span: the length direction from the blade tip to the blade root or from the blade root to the blade tip.

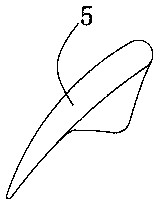

[0031] Airfoil: The cross-sectional shape of the blade.

[0032] Wing Chord: That is, the airfoil chord line refers to the straight line between the leading edge and the trailing edge of the airfoil.

[0033] Asymmetrical airfoil: An airfoil in which the center arc of the airfoil does not coincide with the chord line of the airfoil.

[0034] Airfoil Leading Edge: The front edge of an airfoil.

[0035] Airfoil Trailing Edge: The rear edge of an airfoil.

[0036] Twisted equal-section blade shape: The blade section shape line and cross-sectional area are the same along the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com