Permanent magnet synchronous motor rotor of mixed magnetic steel

A technology of permanent magnet synchronous motors and magnets, which is applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., and can solve the problem of small proportion of motor reluctance torque, easy demagnetization, large consumption of motor magnets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

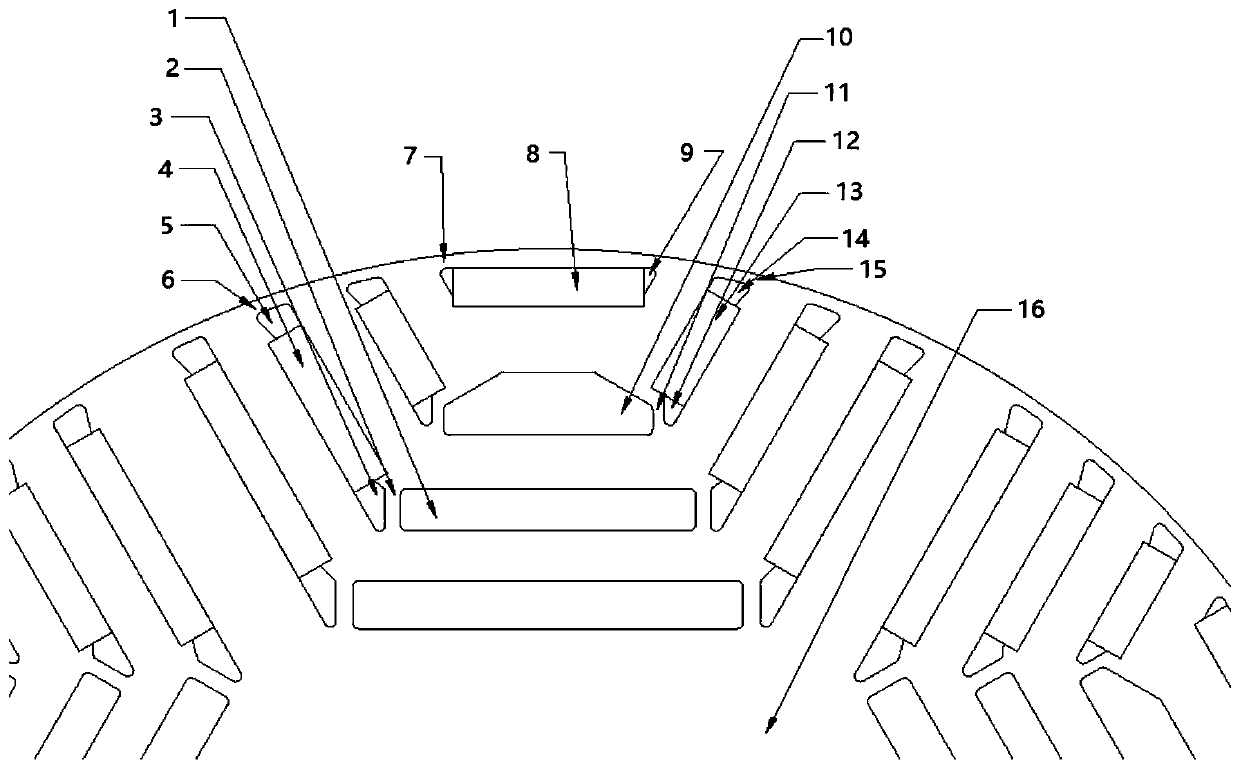

[0022] Such as figure 1 Shown, the permanent magnet synchronous motor rotor of hybrid magnetic steel of the present invention, it is made up of first magnetic steel 8, second magnetic steel 13, the 3rd magnetic steel 4 and rotor iron core 16, the first magnetic steel 8, the second The magnets 13 and the third magnets 4 are alternately distributed and embedded in the rotor core 16, and form several magnetic poles; each pole has N layers of magnets, N is a natural number ≥ 3, the first magnets 8, the second The second magnetic steel 13 and the third magnetic steel 4 are alternately distributed on the magnetic poles in sequence.

[0023] For example, each magnetic pole of the rotor core 16 has N (N is a natural number greater than or equal to 3) layers of magnetic steel, the first layer is 1 piece of first magnetic steel 8, the second layer is 2 pieces of second magnetic steel 13, and the second layer is 2 pieces of second magnetic steel 13. The third layer is composed of two th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com