Discharging and dedusting device on bunker

A technology of dust removal device and ore tank, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of inability to open and close normally, the air volume of dust removal is not large, and the system cannot extract wind and dust, and achieve equipment operation. High efficiency, good filtration efficiency, and the effect of improving the working environment of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

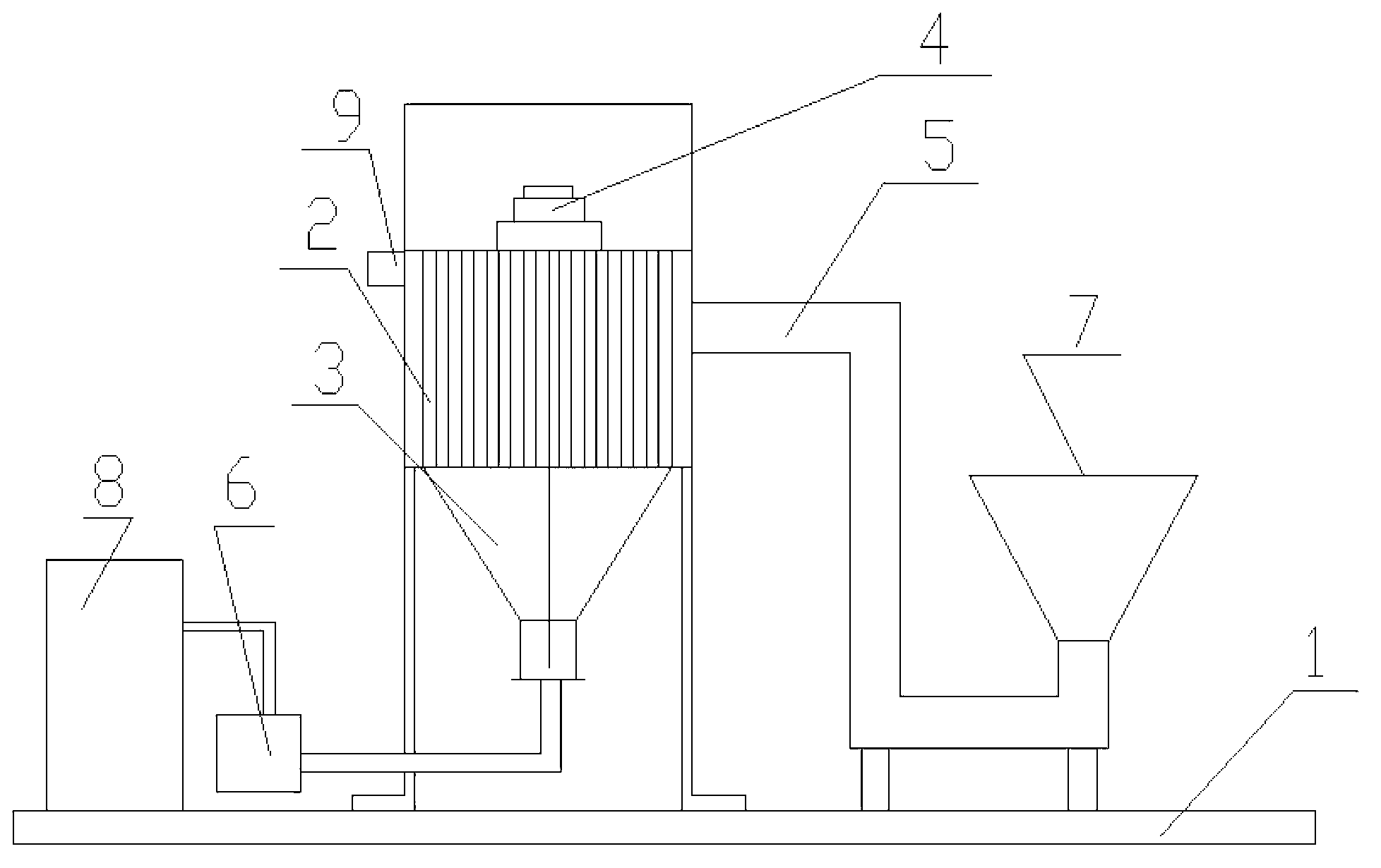

[0011] like figure 1 As shown, the unloading and dedusting device on a mine tank of the present invention includes a mobile unloading car, guide rails, and the guide rails are installed on both sides of the mobile unloading car in parallel, and the mobile unloading car is placed on the guide rails by wheels. A support platform 1 is set on the feeder, and the support platform 1 is equipped with a bag filter 2, a dust collecting bucket 3, a sonic cleaner 4, a dust removal pipeline 5, and a centrifugal fan 6, and the dust collecting bucket 3 is set on the bag filter 2, the sonic dust cleaner 4 is set above the bag filter 2, the centrifugal fan 6 communicates with the lower part of the dust collecting bucket 3 through a pipeline, and one end of the dust removal pipeline 5 is provided with an ash suction port 7, which is connected with the mobile unloading truck. The ash outlet is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com