Method for preparing palladium nano-particles by plant biomass reduction method

A technology of palladium nanoparticles and plant biomass, which is applied in the field of preparing palladium nanoparticles by plant biomass reduction method, achieving the effects of good dispersion, stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

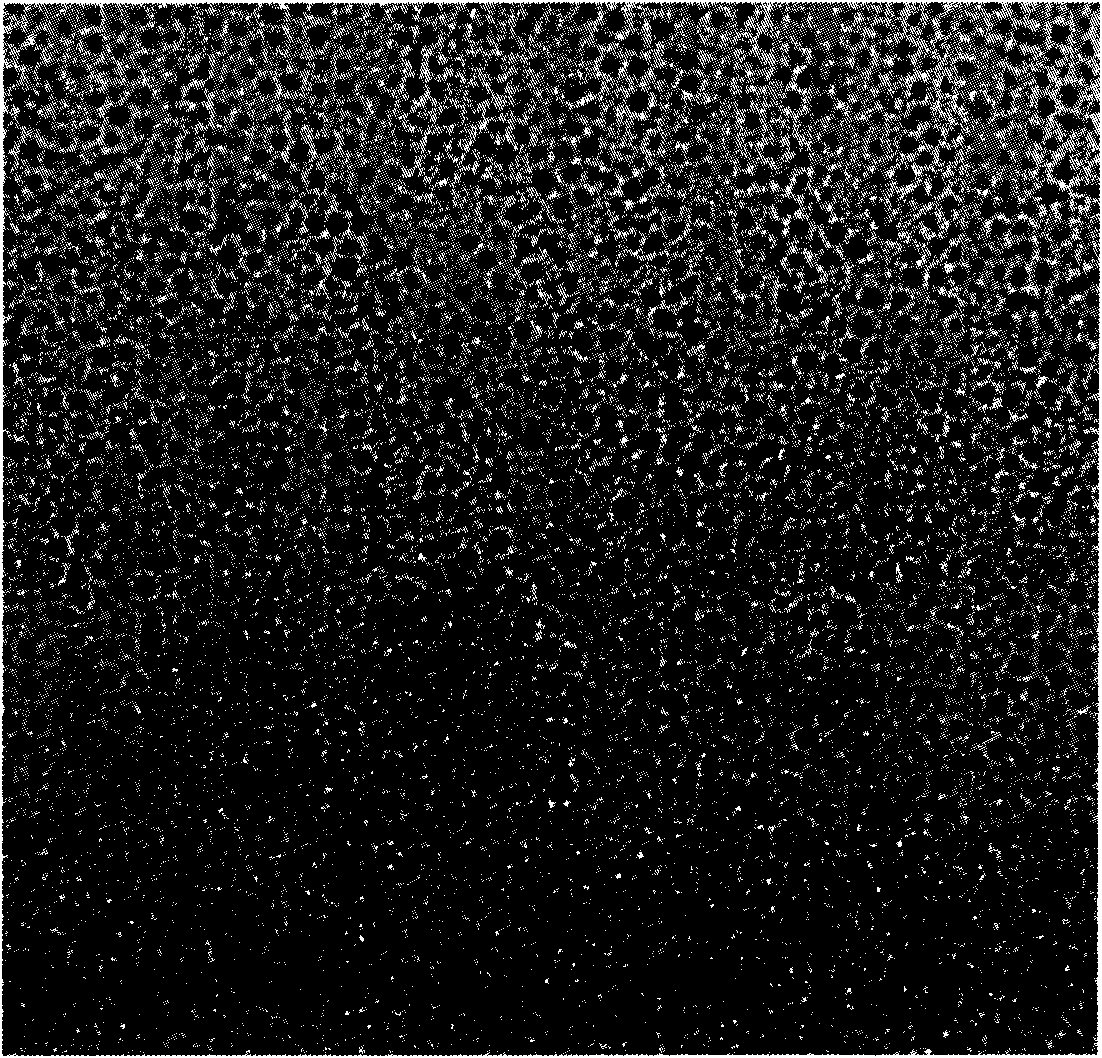

Embodiment 1

[0019] Weigh 2g of dry powder of camphor leaves, add 100mL of water, keep for 5min after boiling, and filter the resulting filtrate, which is the aqueous extract of camphor with a concentration of 20.0g / L. Take 25mL of Cinnamomum camphora aqueous extract and 25mL of palladium chloride solution (0.01mol / L) to react in a 100mL Erlenmeyer flask, and control the reaction temperature to 30°C. After reacting 48h, observe gained palladium sol with transmission electron microscope (TEM), observation result (see figure 1 ) shows that the obtained palladium nanoparticles are nearly spherical, uniform in size, most of the particle diameters are distributed in the range of 2.0-4.5nm, and the average particle diameter is 3.2nm.

Embodiment 2

[0021] Adopt 25mL of Cinnamomum camphora aqueous extract in embodiment 1, react in 100mL Erlenmeyer flask with 25mL palladium chloride solution (0.006mol / L), control reaction temperature is 30 ℃, the gained palladium nanoparticles after reacting 60h are nearly Spherical, most of the particle size distribution is 2.5-5.5nm, and the average particle size is 4.0nm.

Embodiment 3

[0023] Adopt 25mL of Cinnamomum camphora aqueous extract in embodiment 1, react in 100mL Erlenmeyer flask with 25mL palladium chloride solution (0.002mol / L), control reaction temperature is 30 ℃, gained palladium nanoparticles after reaction 70h are nearly Spherical, most of the particle size distribution is 4.5-8.0nm, and the average particle size is 6.0nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com