Method for preparing Pd/foamed metal catalyst for hydrogenolysis dechlorination

A foam metal and catalyst technology, which is applied in the field of preparation of palladium/foam metal catalyst, can solve the problems of high energy consumption, equipment cost, catalyst deactivation and the like, and achieves the effects of good stability, high degree of dispersion and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

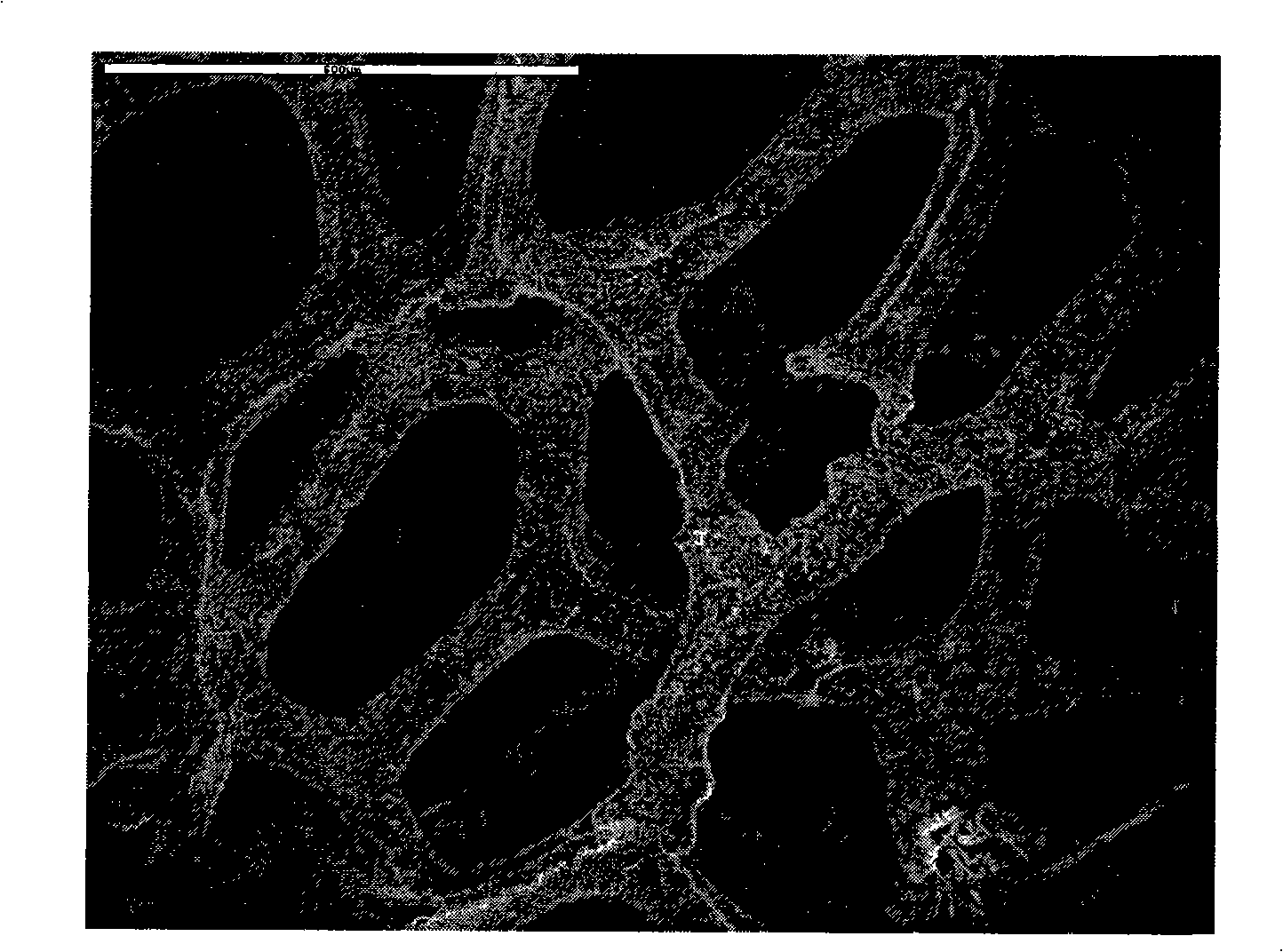

[0021] Embodiment 1: nickel foam supported palladium catalyst technology and dechlorination reaction process

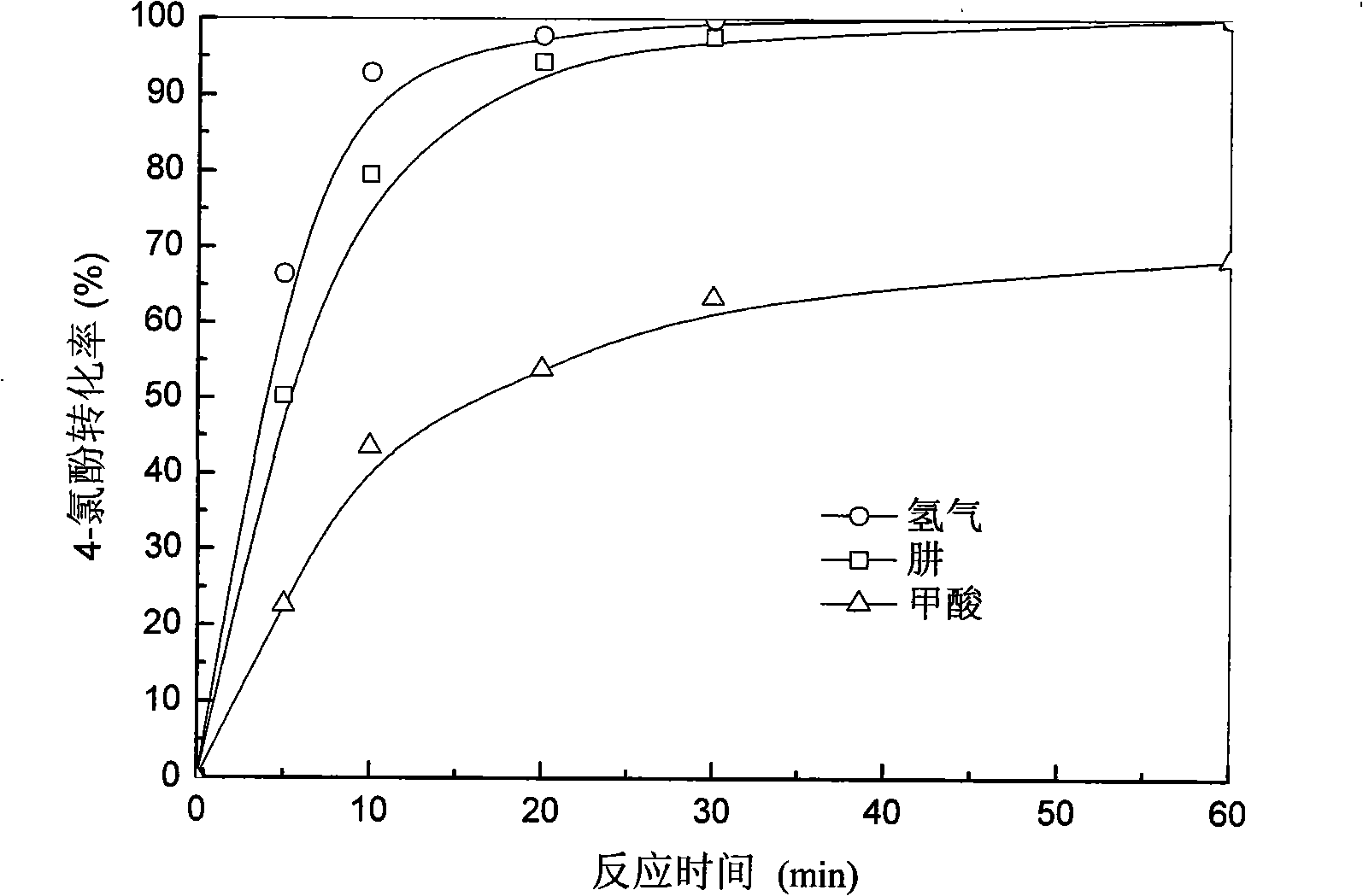

[0022] Cut out the required size of nickel foam (99.9%, thickness 2.0mm, S BET : 1.2217±0.1296m 2 / g, pore density: 130ppi), load according to the following steps: (1) the foamed nickel sheet is cut into a small block of 2mm × 2mm size, and the foamed nickel small block of about 0.3g is weighed and put into the acetone solution, Ultrasonic for 40-60 minutes to degrease, take them all out and rinse them with clean water, then put them into 80g / L sulfuric acid solution and ultrasonically for 60-180s to remove the oxide layer, then wash and drain with clean water; (2) 0.3g of the present embodiment The initial size of nickel foam before cutting is 1.4×4.8cm 2 , the required palladium loading is 3.5mg / cm 2 (geometric size), thus calculate and prepare 22mL 10mMPdCl according to the load calculation formula 2 +30mMNaCl (molar ratio 1:3) deposition solution (i.e. chemica...

Embodiment 2

[0024] Embodiment 2: foam copper supported palladium catalyst technology and dechlorination reaction process

[0025] The catalyst preparation process and reaction performance evaluation conditions are the same as in Example 1, except that the carrier is made of foamed copper material, and the time for ultrasonically removing the oxide layer in 80g / L sulfuric acid solution is 30-40s. When the catalyst is used for hydrodechlorination of 4-chlorophenol, the conversion rate of chlorophenol after 20 minutes of reaction is 98.6%, which is slightly higher than the dechlorination efficiency of palladium / nickel foam.

Embodiment 3

[0026] Embodiment 3: foam iron supported palladium catalyst technology and dechlorination reaction process

[0027] The catalyst preparation process and reaction performance evaluation conditions are the same as in Example 1, except that the carrier is made of foamed iron material, and the time for ultrasonically removing the oxide layer in 80g / L sulfuric acid solution is 10-30s. When the catalyst is used for hydrodechlorination of 4-chlorophenol, the conversion rate of 4-chlorophenol is 92.1% after 20 minutes of reaction, which is slightly lower than the dechlorination efficiency of palladium / nickel foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com