Water-based pressure sensitive adhesive as well as preparation method and application thereof

A pressure-sensitive adhesive, water-based technology, applied in the direction of adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problems of poor colloidal strength, poor bonding performance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

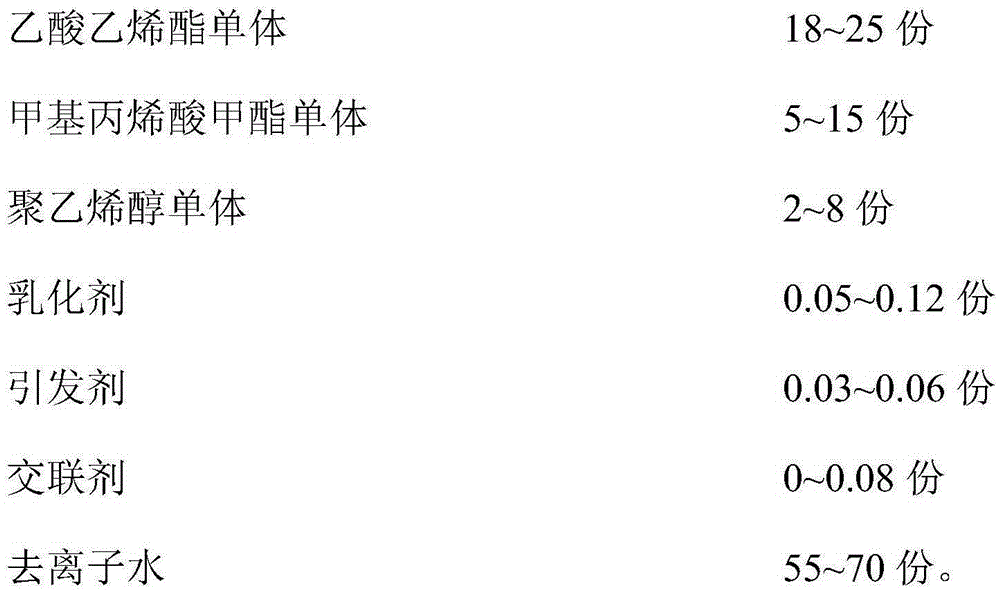

[0070] (1) Preparation of acrylate emulsion:

[0071] In a four-necked flask equipped with an electric stirrer, a reflux condenser, a thermometer and a constant pressure dropping funnel, add 60 parts by weight of deionized water, raise the temperature to 83°C, and then add 20 parts of vinyl acetate dropwise in sequence Monomer, 10 parts of methyl methacrylate monomer, 5 parts of polyvinyl alcohol monomer, 0.08 part of emulsifier sodium laurate and a mixture of alkylphenol polyoxyethylene ether (wherein, dodecyl The mass ratio of sodium base acid and alkylphenol polyoxyethylene ether is 3:2), 0.04 parts of initiator ammonium persulfate, 0.04 parts of crosslinking agent trimethylolpropane and triethanolamine, and the above raw materials are all in Dropping is completed within 2.5-3 hours, then raise the temperature to 90°C, react for 0.7 hours, drop the temperature at the same time at a rate of 10-20 drops / min, slowly add 10 parts of sodium bicarbonate aqueous solution to adjust...

Embodiment 2

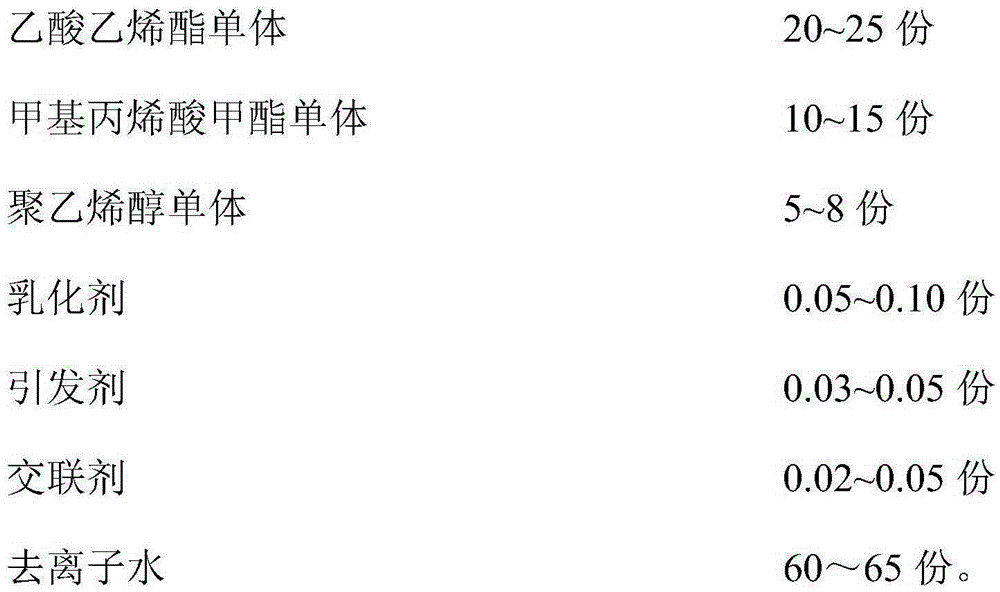

[0078] (1) Preparation of acrylate emulsion:

[0079] In a four-neck flask equipped with an electric stirrer, a reflux condenser, a thermometer and a constant pressure dropping funnel, add 70 parts by weight of deionized water, raise the temperature to 85°C, and then add 25 parts of vinyl acetate dropwise in sequence Monomer, 15 parts of methyl methacrylate monomer, 8 parts of polyvinyl alcohol monomer, 0.12 part of emulsifier alkylphenol ethoxylate, 0.06 part of initiator potassium persulfate, 0.08 part of crosslinking Add maleic anhydride, the above raw materials are all dropped within 2.5~3h, then raise the temperature to 95°C, react for 0.5h, cool down and slowly add 15 parts of ammonium bicarbonate aqueous solution at a rate of 10~20 drops / min to adjust the pH To 6.5, filter to obtain acrylate emulsion;

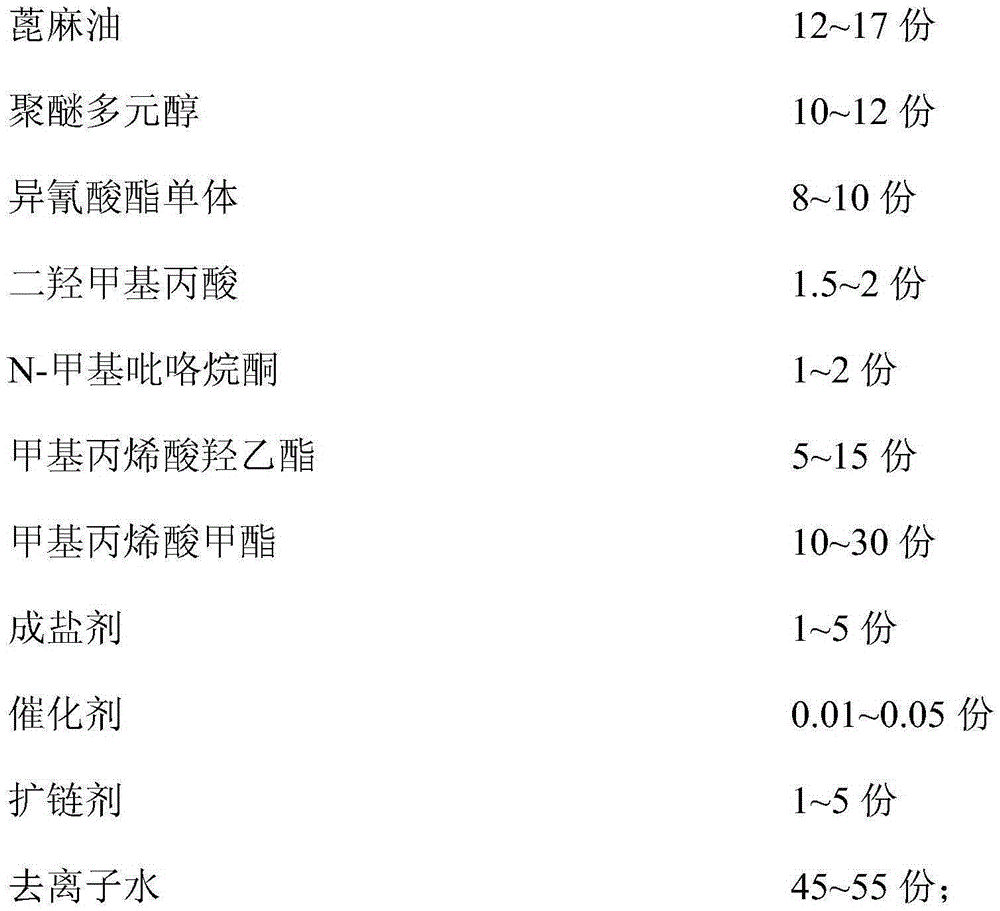

[0080] (2) Preparation of castor oil-based polyurethane prepolymer:

[0081] Pretreatment of castor oil: vacuum dehydration of castor oil castor oil at 120°C for 3h; ...

Embodiment 3

[0086] (1) Preparation of acrylate emulsion:

[0087] In a four-neck flask equipped with an electric stirrer, a reflux condenser, a thermometer and a constant pressure dropping funnel, add 55 parts by weight of deionized water, raise the temperature to 80°C, and then add 18 parts of vinyl acetate dropwise in sequence Monomer, 5 parts of methyl methacrylate monomer, 2 parts of polyvinyl alcohol monomer, 0.05 part of emulsifier sodium laurylate, 0.03 part of initiator ammonium persulfate and potassium persulfate mixture, the above The raw materials are all dropped within 2.5-3 hours, then heated up to 85°C, reacted for 1 hour, and at the same time lowered the temperature at a rate of 10-20 drops / min, slowly added 8 parts of sodium bicarbonate aqueous solution to adjust the pH to 5, and filtered to obtain acrylate Lotion;

[0088] (2) Preparation of castor oil-based polyurethane prepolymer:

[0089] Pretreatment of castor oil: vacuum dehydration of castor oil castor oil at 130°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com