Pressure-sensitive adhesive composition, pressure-sensitive adhesive, and adhesive sheet using same

A technology of adhesives and compositions, applied in the direction of non-polymer adhesive additives, adhesive additives, film/sheet adhesives, etc., can solve the problems of unsuitable electronic components for fixed purposes, and achieve excellent cohesion , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

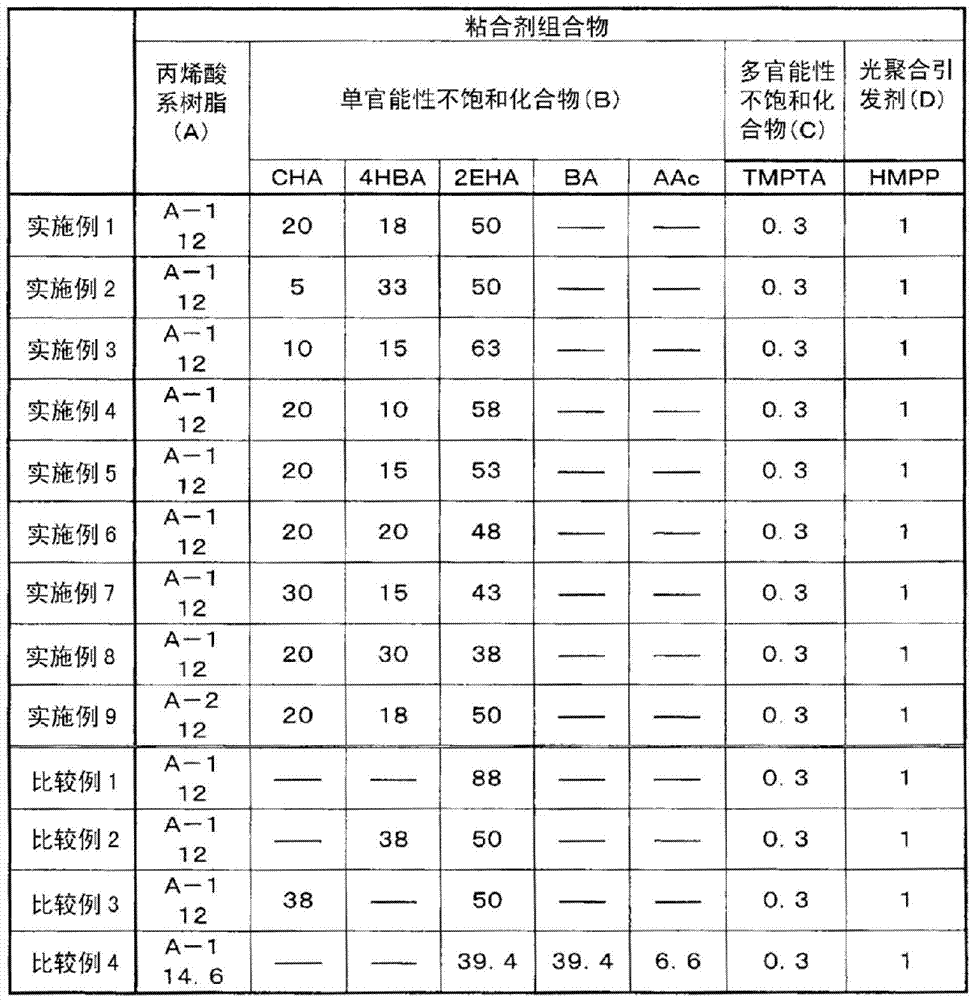

[0144] 12 parts of acrylic resin (A-1) as acrylic resin (A), 18 parts of 4-hydroxybutyl acrylate (HBA: (B2)) as monofunctional unsaturated compound (B), 20 parts Cyclohexyl acrylate (CHA: (B1)), 50 parts of 2-ethylhexyl acrylate (2EHA: (B3)), 0.3 part of trimethylolpropane triacrylic acid as polyfunctional unsaturated compound (C) The ester (TMPTA) was added to a vessel with a stirrer and stirred and mixed for 24 hours to dissolve. By mixing 1 part of 2-hydroxy-2-methyl-1-phenyl-propan-1-one (trade name: "Darocur1173"; manufactured by Ciba Specialty Chemicals Inc. )(HMPP) to obtain an adhesive composition.

[0145] The pressure-sensitive adhesive composition obtained above was coated on a polyethylene terephthalate (PET) substrate having a thickness of 100 μm so as to have a thickness of 130 μm. Furthermore, using the PET substrate subjected to the mold release treatment, the coating surface was covered so that the mold release treatment surface came into contact with the co...

Embodiment 2~8

[0151]In Example 1, the compounding ratios of 4-hydroxybutyl acrylate (HBA), cyclohexyl acrylate (CHA) and 2-ethylhexyl acrylate (2EHA) were changed as shown in Table 1 below, Except that, it carried out similarly to Example 1, and obtained the adhesive composition and the adhesive sheet.

Embodiment 9

[0153] In Example 1, the acrylic resin (A-2) was used instead of the acrylic resin (A-1), and the compounding ratio of other components was changed as shown in the following Table 2, except that it was the same as in Example 1. Operation, obtain adhesive composition and adhesive sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com