Preparation method of hyperbranched ternary polymerization organic silicon

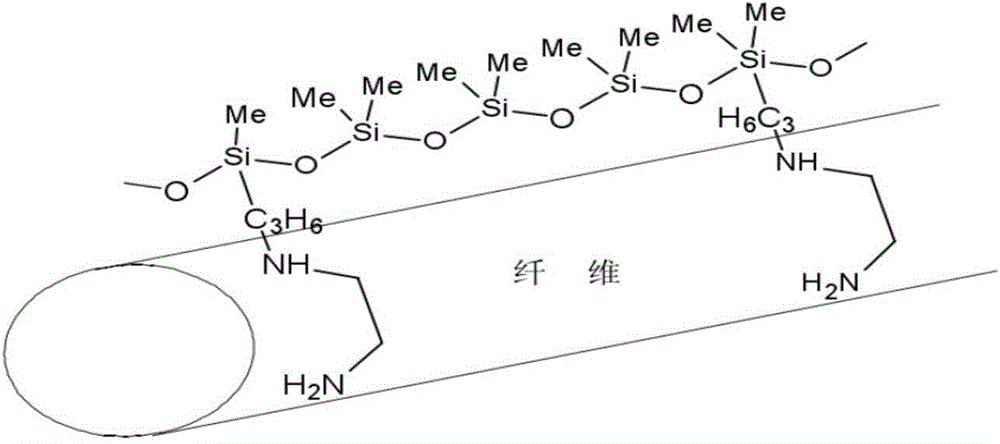

A hyperbranched ternary, silicone technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of poor washability, softness and smoothness not as good as amino silicone oil, etc., to increase hydrophilicity, good anti-contamination, The effect of increasing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] A preparation method of hyperbranched ternary copolymerization organosilicon, comprising the steps of:

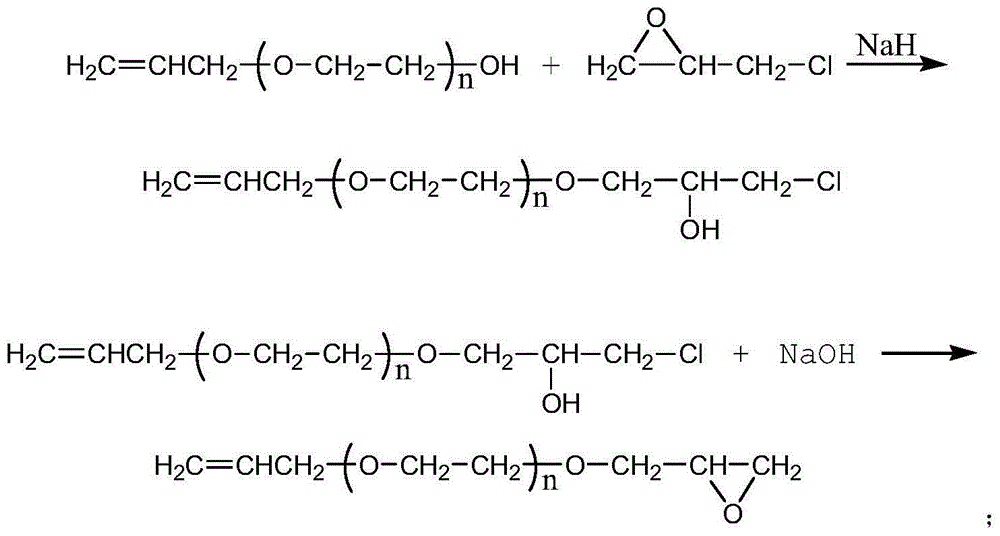

[0039] (1) Preparation of allyl polyoxyethylene glycidyl ether:

[0040] Mix allyl polyoxyethylene ether and epichlorohydrin evenly, use sodium hydride as a catalyst, react at 55°C for 1.5h, and then remove excess epichlorohydrin under reduced pressure; then add a certain amount of amount of sodium hydroxide aqueous solution, and control the reaction temperature at 30°C for 1.5 hours; after the reaction, undergo post-processing such as vacuum distillation and filtration to remove impurities to obtain end-capped polyether products. The degree of polymerization of the allyl polyoxyethylene ether is 19. The molar ratio of allyl polyoxyethylene ether, epichlorohydrin and sodium hydroxide is 1:1.4:1.3.

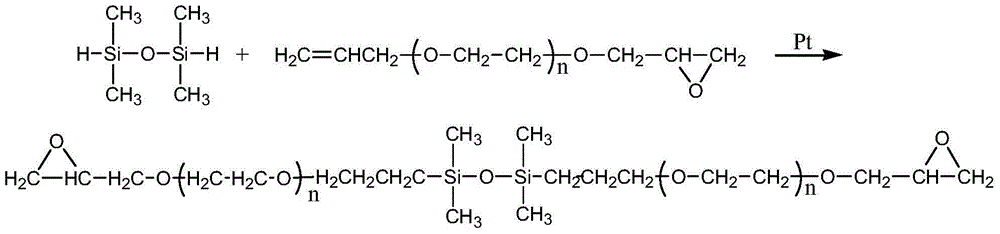

[0041] (2) Preparation of epoxy-terminated polyether block siloxane:

[0042] Mix tetramethyldihydrodisiloxane and allyl polyoxyethylene glycidyl ether in a ratio of 1...

specific Embodiment 2

[0047] A preparation method of hyperbranched ternary copolymerization organosilicon, comprising the steps of:

[0048] (1) Preparation of allyl polyoxyethylene glycidyl ether:

[0049] Mix allyl polyoxyethylene ether and epichlorohydrin evenly, use sodium hydride as a catalyst, react at 65°C for 2.5 hours, and then remove excess epichlorohydrin under reduced pressure; then add a certain amount of Amount of sodium hydroxide aqueous solution, control the reaction temperature and react at 40°C for 3 hours; after the reaction, undergo post-processing such as vacuum distillation and filtration to remove impurities to obtain end-capped polyether products. The degree of polymerization of the allyl polyoxyethylene ether is 25. The molar ratio of allyl polyoxyethylene ether, epichlorohydrin and sodium hydroxide is 1:1.4:1.3.

[0050] (2) Preparation of epoxy-terminated polyether block siloxane:

[0051] Mix tetramethyldihydrodisiloxane and allyl polyoxyethylene glycidyl ether in a r...

specific Embodiment 3

[0056] A preparation method of hyperbranched ternary copolymerization organosilicon, comprising the steps of:

[0057] (1) Preparation of allyl polyoxyethylene glycidyl ether:

[0058] Mix allyl polyoxyethylene ether and epichlorohydrin evenly, use sodium hydride as a catalyst, react at 60°C for 2 hours, and then remove excess epichlorohydrin under reduced pressure; then add a certain amount of Sodium hydroxide aqueous solution, the reaction temperature is controlled at 35 °C for 2 hours; after the reaction is completed, the end-capped polyether product is obtained by post-processing such as vacuum distillation and filtration to remove impurities. The degree of polymerization of the allyl polyoxyethylene ether is 23. The molar ratio of allyl polyoxyethylene ether, epichlorohydrin and sodium hydroxide is 1:1.4:1.3.

[0059] (2) Preparation of epoxy-terminated polyether block siloxane:

[0060] Mix tetramethyldihydrodisiloxane and allyl polyoxyethylene glycidyl ether in a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com