Production of a Platinum-Free Chelate Catalyst Material as an Intermediate Product, and Further Processing Thereof to Obtain an Electrocatalytic Coating as a Final Product

a technology of chelate catalyst and platinum-free chelate, which is applied in the direction of physical/chemical process catalyst, cell components, sustainable manufacturing/processing, etc., can solve the problems of unsatisfactory catalytic performance characteristics, disadvantageous surface quality of materials, and cathode poisoning, etc., to improve the catalytic capacity, simple, efficient, cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

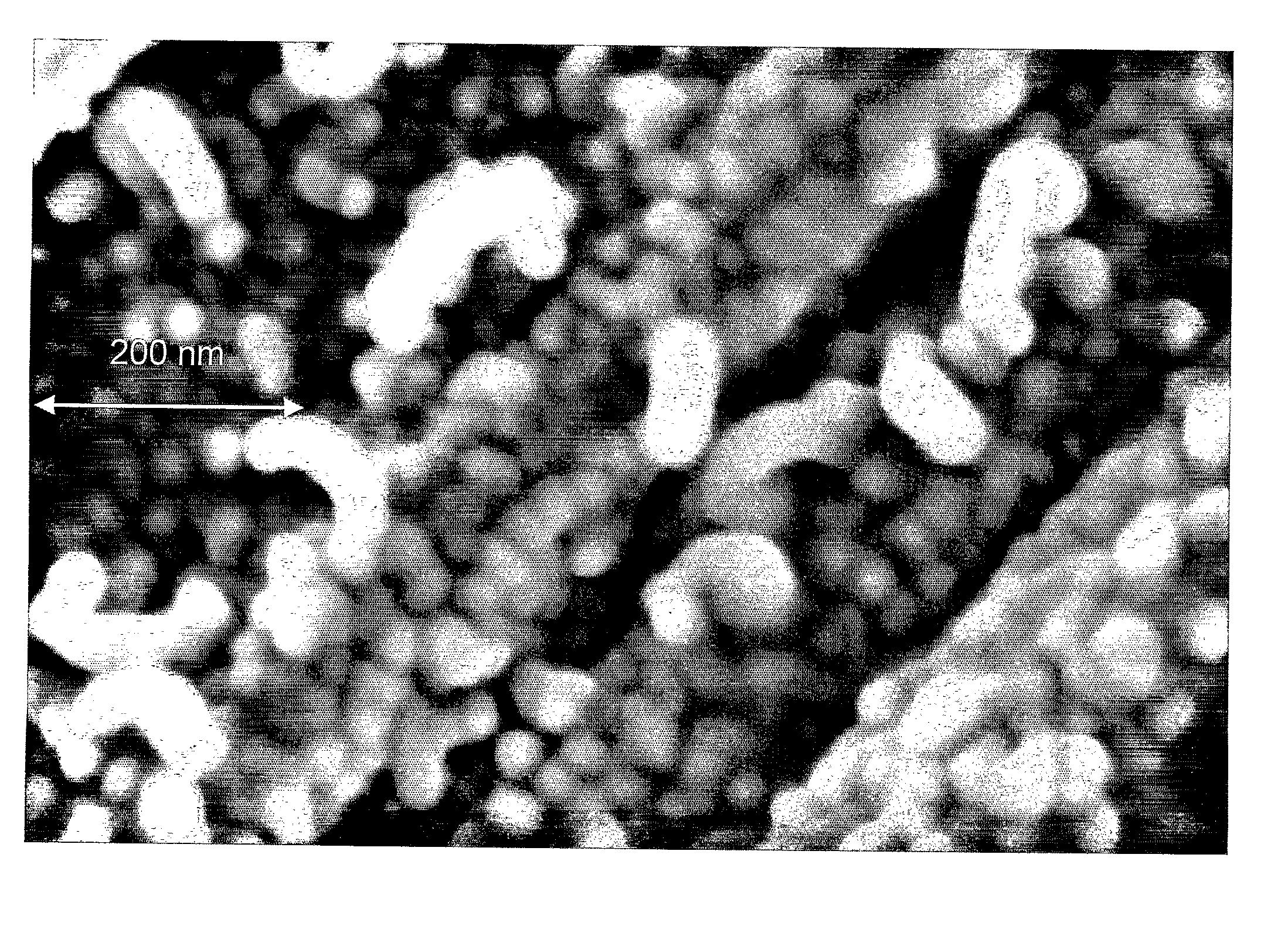

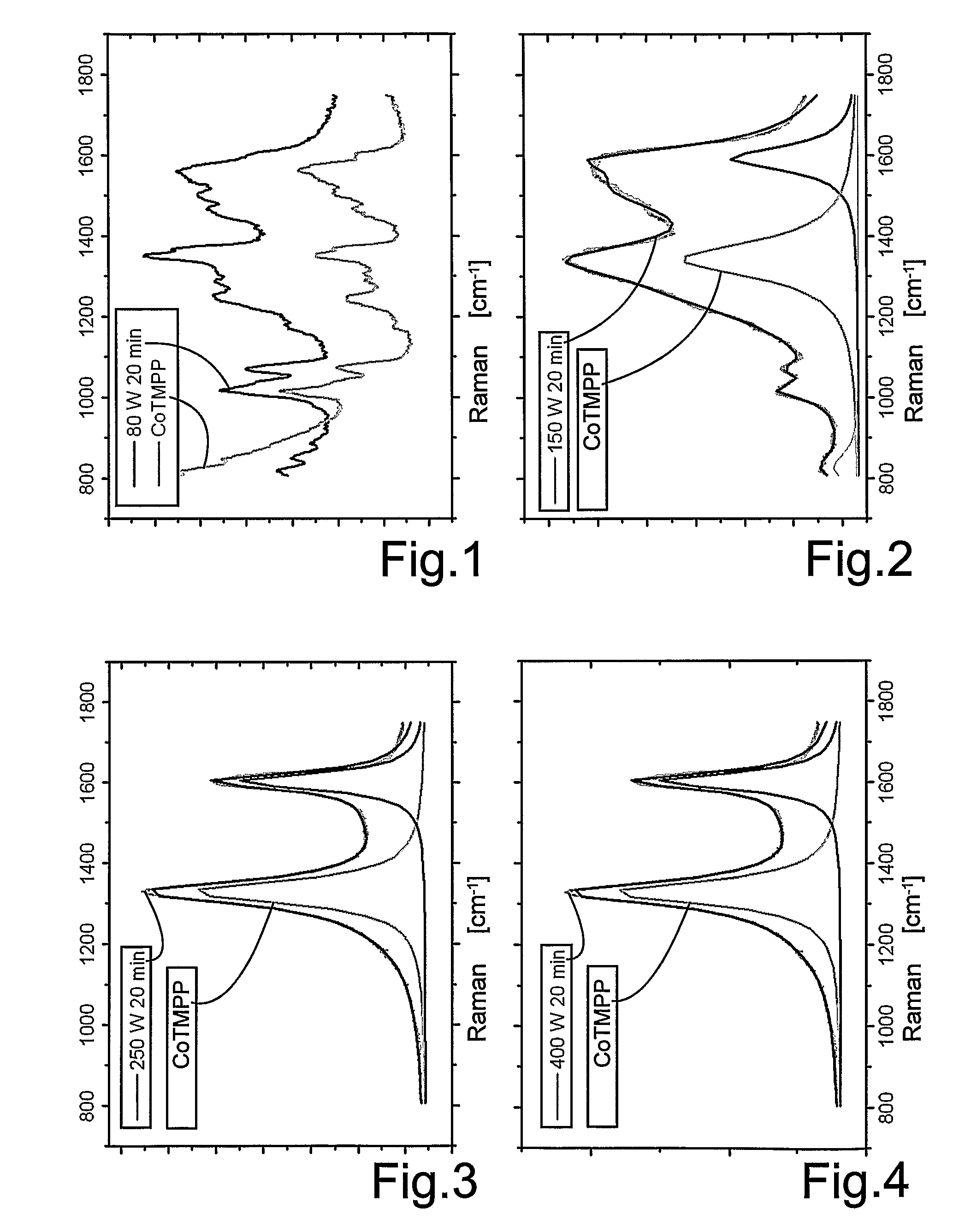

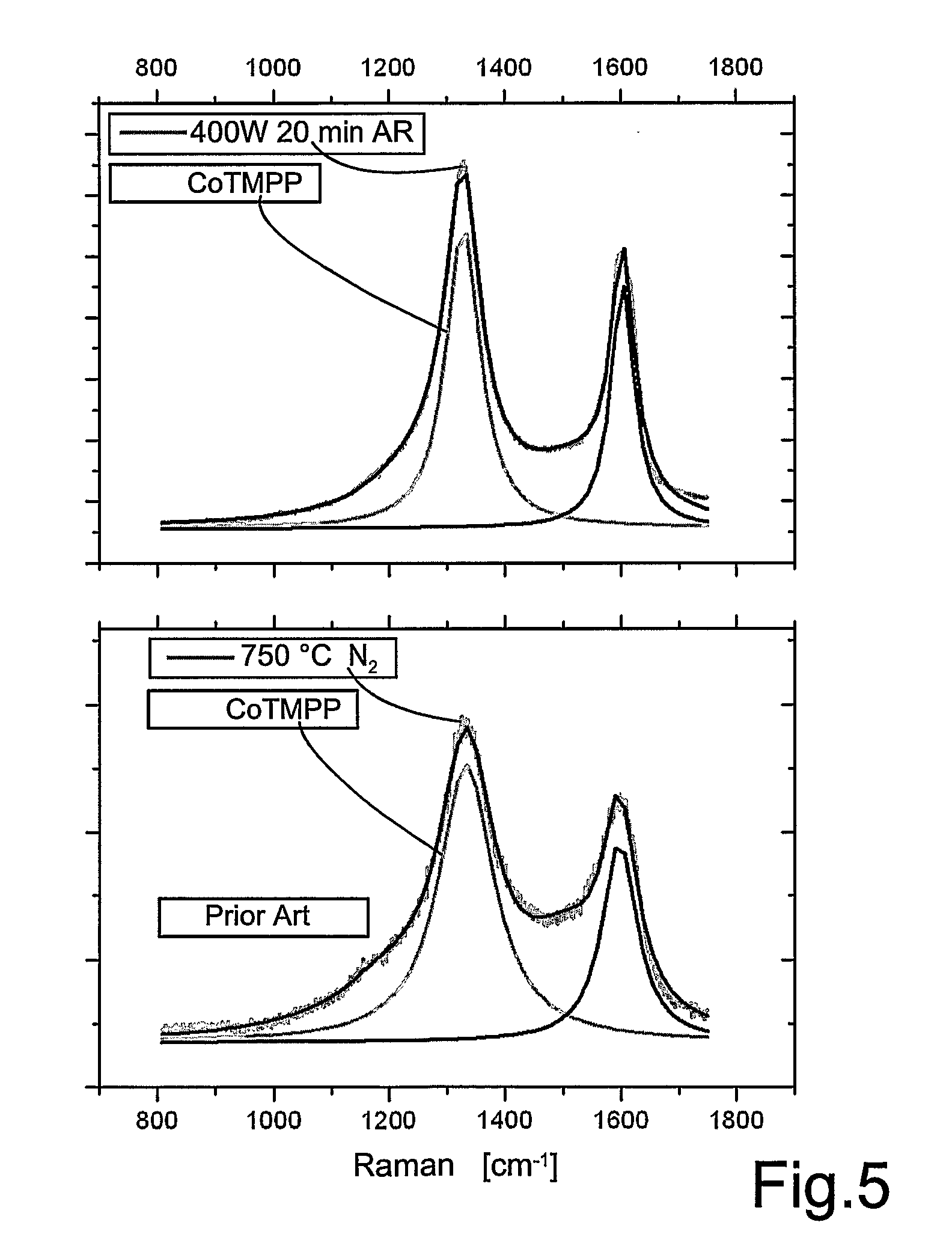

[0033]By employing the plasma treatment, during which a great deal of electronic, but only little thermal energy is transferred to the molecules (this is characteristic of a low-temperature plasma, also referred to as a nonthermal plasma, since only the light electrons are a few ten thousand degrees hot, however, the ions and neutral particles are virtually at room temperature), a chelate catalyst material may be obtained, which, due to negligible sintering and thus production of nanoscale particles having a large, catalytically active surface, has a higher activity for the electrocatalytic reaction of the oxygen reduction than conventional thermal treatments. A chelate catalyst material made of an electrically conductive carbon matrix having embedded, electrochemically active centers is prepared by the method according to the present invention. The plasma treatment controls the fragmentation of the chelate molecules as starting material, the cross-linking of these fragments as a ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas pressure | aaaaa | aaaaa |

| plasma power | aaaaa | aaaaa |

| plasma gas pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com